In the fields of engineering manufacturing and product design, surface flatness affects not only aesthetic appeal but also assembly precision and operational safety. A countersink hole is a fundamental and critical type of hole processing, with its core value lying in achieving a seamless integration between fasteners and the workpiece surface.

Mastering the process specifications and application techniques of countersinking is an essential foundation for every engineer to ensure products meet industrial standards. This technical guide provides a comprehensive overview of countersink holes, from definitions and construction steps to common troubleshooting.

What is a Countersink Hole?

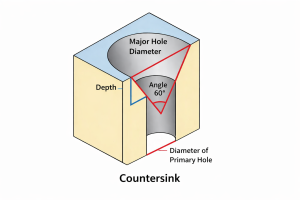

A countersink hole refers to a conical enlargement processed at the opening of an existing cylindrical hole in a workpiece. Its primary design purpose is to provide a recessed space for countersunk screws (flat-head screws), allowing the screw head to sit flush with or slightly below the surface of the workpiece once tightened.

From a geometric perspective, a standard countersink hole consists of two parts: a cylindrical pilot hole at the bottom and a conical recess at the top. This structure not only improves the tidiness of the exterior but also prevents protruding bolt heads from snagging objects or causing scratches, which is particularly vital in tight assembly spaces.

How to Drill a Countersink Hole

Processing a countersink hole is not a simple matter of enlarging the hole diameter; it is a professional cutting process that requires precise control over depth and angle. To ensure the hole is flat and fits the screw perfectly, it is recommended to follow these standardized steps:

Drilling a Pilot Hole

Before processing the countersink, a pilot hole must be drilled. The diameter of the pilot hole should be slightly larger than the nominal thread diameter of the screw, typically by 0.2 to 0.5 mm. It is essential to ensure the pilot hole is perpendicular to the surface; if the pilot hole is tilted, the subsequent countersink will also be tilted, preventing the screw head from sitting flush.

Selecting and Installing the Countersink Bit

Select a countersink bit that matches the screw specifications and the required angle, such as 90 degrees. When loading the bit into a drill press or hand drill, always check its runout to prevent an uneven or polygonal hole shape caused by an off-center axis.

Setting the Depth Limit

For precision machining or mass production, it is recommended to install a depth stop on the drill press or bit. If a hardware limit is unavailable, perform a test cut on scrap material first. Measure the depth needed for the screw to sit perfectly flush and mark the feed scale to ensure consistency across multiple holes.

Commencing Drilling and Chip Removal

Start the drill and begin cutting at a low rotation speed. Follow the principle of short-stroke feeding, which involves drilling to a certain depth and then slightly lifting the bit. This helps remove debris from the conical surface, preventing chip buildup from scratching the hole wall or causing chatter marks.

Inspection and Fine-tuning

After reaching the target depth, stop the machine and place a screw into the hole for a test fit. Ideally, the screw head should sit approximately 0.1 mm below the surface to account for the thickness of subsequent coatings or paint. If the depth is insufficient, restart the drill and deepen the cut slightly.

Types of Countersink Holes

The geometric profile of a countersink must precisely match the taper of the fastener to ensure uniform load distribution. Depending on the fastener head shape and the applicable engineering standards, common types of countersink holes include:

Classification by Fastener Standard and Angle

-

90° Countersink: The universal standard for metric fasteners.

-

82° Countersink: The typical specification for imperial (Unified Thread Standard) fasteners.

-

Special Application Angles: Depending on specific engineering requirements, angles such as 60°, 100°, 110°, and 120° are also utilized.

Classification by Engineering Functional Form

-

Flat Head Countersink: The most widely used form, featuring a conical recess with a flat top. The included angle is typically 82° for commercial hardware (especially in woodworking) and often 100° for riveting or specific aerospace hardware applications.

-

Oval Head Countersink: Specifically designed for oval head screws that feature a slightly convex and smooth exterior. The included angle is typically 100°, frequently used in industrial designs such as molding and trim where both fastening and aesthetics are required.

-

Round Head Countersink: Although less common, this type pairs effectively with round head screws. It is typically used in specialized cases where a protruding, decorative screw head is desired as a design feature, or when installing flat-profile fasteners onto hardware that does not natively feature countersink holes.

Dimensions of Countersink Holes

In engineering drawings, dimensional specifications must be strictly followed to ensure fit precision. Below is a reference table for common countersink dimensions based on ISO standards:

Countersunk Hole Size Chart for Flat Head Fasteners (ISO)

All dimensions are in millimetres apart from the countersink angle.

Data Source: The Engineer’s Bible – ISO Countersunk Data

| Fastener Size (Thread) | Pilot Hole Diameter (Close Fit H12) | Pilot Hole Diameter (Normal Fit H13) | Pilot Hole Diameter (Loose Fit H14) | Countersink Diameter | Countersink Angle (°) |

| M3 | 3.2 | 3.4 | 3.6 | 6.94 | 90 |

| M3.5 | 3.7 | 3.9 | 4.2 | 8.96 | 90 |

| M4 | 4.3 | 4.5 | 4.8 | 9.18 | 90 |

| M5 | 5.3 | 5.5 | 5.8 | 11.47 | 90 |

| M6 | 6.4 | 6.6 | 7 | 13.71 | 90 |

| M8 | 8.4 | 9 | 10 | 18.25 | 90 |

| M10 | 10.5 | 11 | 12 | 22.73 | 90 |

| M12 | 13 | 13.5 | 14.5 | 27.21 | 90 |

| M16 | 17 | 17.5 | 18.5 | 33.99 | 90 |

| M20 | 21 | 22 | 24 | 40.71 | 90 |

Countersunk Hole Size Chart for 82 Degree Machine Fasteners (ANSI Inch)

All dimensions are in inches apart from the countersink angle.

Data Source: The Engineer’s Bible – ANSI 82° Countersunk Data

| Fastener Size (Thread) | Pilot Hole Diameter (Close Fit) | Pilot Hole Diameter (Normal Fit) | Pilot Hole Diameter (Loose Fit) | Countersink Diameter | Countersink Angle |

| #0 | 1/15 | 6/79 | 3/32 | 5/42 | 82 |

| #1 | 3/37 | 4/45 | 8/77 | 13/89 | 82 |

| #2 | 3/32 | 7/69 | 7/62 | 16/93 | 82 |

| #3 | 5/47 | 8/69 | 9/70 | 1/5 | 82 |

| #4 | 3/25 | 9/70 | 14/97 | 9/40 | 82 |

| #5 | 9/64 | 5/32 | 11/64 | 25/99 | 82 |

| #6 | 2/13 | 10/59 | 5/27 | 12/43 | 82 |

| #8 | 9/50 | 10/51 | 13/61 | 1/3 | 82 |

| #10 | 15/73 | 21/95 | 5/21 | 5/13 | 82 |

| #12 | 15/64 | 15/61 | 6/23 | 39/89 | 82 |

| 1/4 | 17/64 | 9/32 | 19/64 | 36/71 | 82 |

| 5/16 | 21/64 | 11/32 | 23/64 | 40/63 | 82 |

| 3/8 | 25/64 | 13/32 | 27/64 | 16/21 | 82 |

| 7/16 | 29/64 | 15/32 | 31/64 | 69/85 | 82 |

| 1/2 | 17/32 | 9/16 | 39/64 | 7/8 | 82 |

| 9/16 | 19/32 | 5/8 | 43/64 | 1 | 82 |

| 5/8 | 21/32 | 11/16 | 47/64 | 1 1/8 | 82 |

| 3/4 | 25/32 | 13/16 | 29/32 | 1 3/8 | 82 |

Applications and Uses of Countersink Holes

Countersink designs are widely utilized in scenarios with strict requirements for surface quality, space utilization,

and fluid dynamics. Their primary functional applications include:

Maintaining Surface Smoothness and Fluid Dynamics

In structural components where absolute surface flatness is required (such as the outer skins of high-speed vehicles), countersink holes ensure that fasteners do not disrupt surface continuity. This effectively reduces fluid drag and prevents turbulence or aerodynamic noise during high-speed operation.

Prevention of Mechanical Interference and Space Optimization

In precision assemblies or compact mechanical structures, countersinking eliminates surface protrusions by burying the fastener head within the substrate. This prevents physical interference between moving parts and enables ultra-thin designs, allowing components to stack or slide without obstruction.

Enhancing Operational Safety and Ergonomic Experience

By eliminating exposed bolt heads, countersink holes prevent operators or maintenance personnel from being scratched by sharp metal edges. Furthermore, on handheld devices or industrial products requiring frequent contact, countersinking ensures that fasteners do not disrupt the overall grip or tactile continuity.

Countersink vs. Counterbore

In mechanical design, countersink and counterbore holes are the two most frequently confused features.

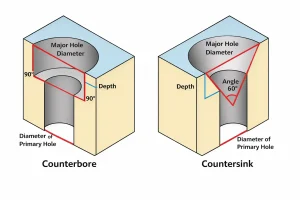

A カウンターシンク features a typical conical (V-shaped) cross-section. The edges of the hole are sloped at a specific angle, designed specifically to accommodate countersunk screws. The slope fits perfectly with the conical underside of the screw head, providing a self-centering function.

In contrast, a カウンターボア appears as a cylindrical (flat-bottomed) enlargement. It features a flat bottom and vertical sidewalls. It is primarily used to accommodate socket head cap screws or other fasteners with flat-bottomed heads. Due to its flat bearing surface, a counterbore can withstand higher tightening pressures.

Other Holes in Engineering

Hole processing is a vast branch of machining, and countersinking is just one part of it:

Common Hole Types Overview

- ブラインドホール: A hole that does not penetrate the back of the part; depth control is key.

- スルーホール: Penetrates the material completely for connection or drainage/venting.

- スポットフェイス: Clears only the rough surface around a hole to provide a flat bearing surface for a washer.

- タップ穴: Features internal threads for direct fastening by screwing in a bolt.

よくあるご質問

What are the two reasons a hole needs to be countersunk?

There are two primary reasons: first, for safety and flatness, eliminating surface protrusions to prevent snagging, interference, or scratches; second, for aerodynamic requirements, maintaining a streamlined surface to reduce drag.

What are common countersinking construction errors?

The most common errors include mismatched angles between the countersink and the screw (e.g., 90° vs. 82°), drilling too deep, and surface chatter caused by excessive rotation speeds.

What are the disadvantages of a countersink hole?

A countersink weakens the material thickness at the hole opening. For thin sheets, this may result in insufficient structural strength or cause the screw head to “pull through” the material under high tension.

How do you repair a countersink hole in engineering?

If a countersink is processed too large, common solutions include using a larger screw size and re-drilling, using dedicated thread repair inserts (such as Helicoils), or filling and re-machining.

結論

A countersink hole is an important design element that balances industrial aesthetics with mechanical function. By utilizing standardized dimensional choices and precise cutting processes, you can significantly improve assembly precision and product durability.

If you would like to optimize your countersink design based on actual parts and materials, you are welcome to upload your drawings and key parameters. Our engineers can help you evaluate size selection and machining solutions.