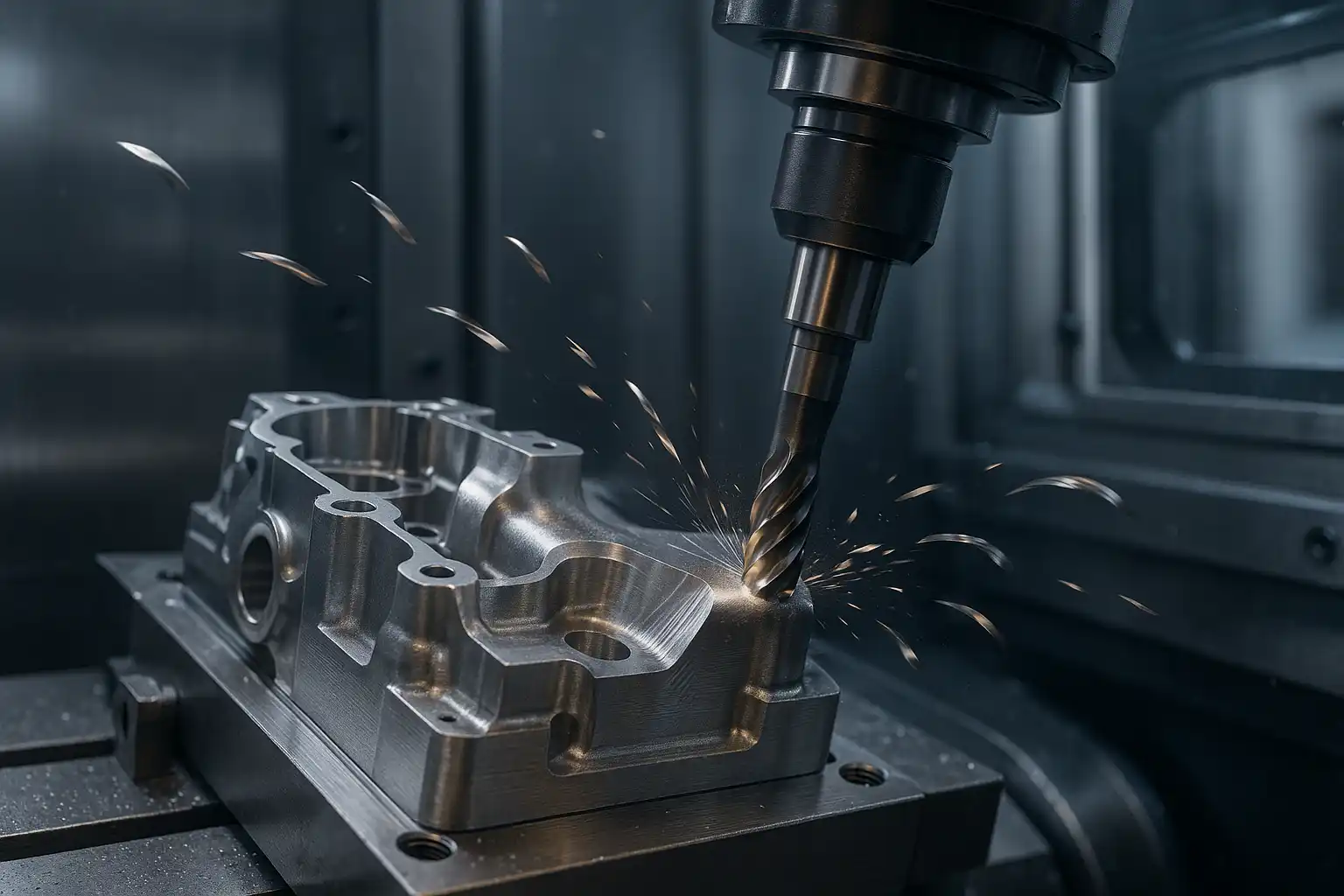

In modern industrial manufacturing, a Computer Numerical Control (CNC) machine tool is the cornerstone for achieving high-precision, high-efficiency production. A high-performance CNC machine is a highly integrated and complex precision system, consisting of the following 13 core components and systems working in close collaboration.

This detailed breakdown ensures that all critical functions, from control to high-precision execution to auxiliary support are distinctly and comprehensively presented.

1. Input Device

The Input Device is the primary means of loading the CNC program onto the machine. This can range from a simple keyboard for direct G-code input, a USB drive containing the full program, or some form of wireless communication for downloading programs from a remote computer.

2. Machine Control Unit (MCU)

The MCU is the collection of software and hardware responsible for reading the input G-code and converting it into the actual operational instructions that the machine and its tools must follow. As one of the most critical components of the entire machine, the MCU drives the servo motors along the axes, ensures the tool is in the correct position upon movement completion, and controls the activation of the tool changer and coolant system.

3. Machine Tool (Tool/Magazine)

This general term refers to any cutting tool used within the machine. Different CNC types handle tools uniquely: CNC lathes hold the tool still while the rotating workpiece moves, while CNC mills rotate the tool and move it toward a stationary workpiece. More complex five-axis machines move both. These tools are typically stored in the tool magazine (or tool library), from which the machine automatically retrieves and returns tools as needed.

4. Drive System

The Drive System comprises the motors that move the tool and the machine bed. On conventional CNC mills, the bed moves horizontally (X and Y axes), and the tool moves vertically (Z axis). On CNC lathes, the tool moves parallel to the rotating workpiece. Servo motors, ball screws, and linear guides are essential to this system, ensuring all parts move synchronously and precisely.

5. Feedback System

The Feedback System acts as the verification mechanism for the drive system, crucial for closed-loop control. While the drive is extremely precise, this system verifies that the part has moved to its intended position. If a deviation is detected, the system uses encoders (sensors measuring component position) to make real-time adjustments. Probes also play a role, measuring the actual workpiece to ensure everything is proceeding as planned.

6. Display Unit

The Display Unit is the operator’s visual interface. It is a screen that displays all vital information during operation, such as machine settings, G-code, and current operational status. Some machines feature large, high-definition screens showing extensive information, while others may have smaller screens showing only essential data.

7. Bed

The Bed is the structural foundation where the raw material is placed. It features numerous holes or T-slots used to mount fixtures that secure the workpiece. While traditional beds move horizontally, advanced five-axis beds may also rotate. On CNC lathes, the tool post and tailstock are mounted on the bed, and the raw material is held by the chuck.

8. Headstock

The Headstock is a key component of the CNC Lathe, typically located on the left side. It houses the main drive gears, bearings, and transmission that rotate the chuck. The headstock is enclosed but often provides access panels for inspection and maintenance.

9. Tailstock

The Tailstock is a lathe component used to support one end of a long, cylindrical workpiece while the chuck holds and rotates the other end. It is vital for preventing material bending during processing. It can be moved along the Z-axis to accommodate different material lengths, making it ideal for machining shafts or screws.

10. Tailstock Quill

The Quill is a tapered structure housed inside the tailstock, aligned with the spindle and chuck. It rotates freely and serves to keep the material centered. For longer workpieces, a blind hole is often drilled into the end of the material for the quill to insert and provide rigid support.

11. Foot Switches or Pedals

These pedals are typically used only on lathes to quickly activate and deactivate the chuck and tailstock quill. Their primary function is to help the operator free their hands for safer and easier loading and unloading of raw blanks and finished products.

12. Chuck

The Chuck is a lathe-specific work-holding device used to clamp and rotate the workpiece during machining. The chuck is typically driven by hydraulics or pneumatics and features three or four jaws (jaws). Three-jaw chucks are self-centering; four-jaw chucks allow for independent jaw movement, offering higher precision and the ability to hold irregular or eccentric shapes.

13. Control Panel

The Control Panel serves as the machine’s main operating station. It integrates the input device, display unit, keyboard, and various control buttons. It is usually mounted on the machine via a retractable arm, allowing the operator to position it optimally.

Conclusion

In modern precision manufacturing, the capability of a CNC machine tool is never determined by a single component, but by the precise collaboration of these 13 core systems. From the CNC Unit that acts as the brain to the closed-loop feedback elements that ensure micron-level accuracy, each system is crucial for guaranteeing part geometric accuracy and batch consistency. Our profound understanding and mastery of these core technologies are the ultimate assurance we offer to our clients seeking the highest quality CNC machined parts.

Request Your Expert Manufacturing Solution

You’ve learned about the 13 core systems that underpin our precision manufacturing capabilities. These technologies ensure we can meet the industry’s most stringent tolerance demands and work with the most complex materials. If you are looking for a partner who can guarantee batch consistency and maximum accuracy for your parts, please request precision manufacturing solutions today.