Choosing the Right 5-Axis CNC Machine for Your Needs

The decision to invest in a 5-axis CNC machine is a big one. You’ve likely considered the potential for greater efficiency, precision, and design freedom. But with so many options on the market, how do you make the right choice without overspending or under-equipping your shop? This guide breaks down what we’ve learned from years of hands-on experience: the real costs, the essential features, and the questions you must ask before you buy.

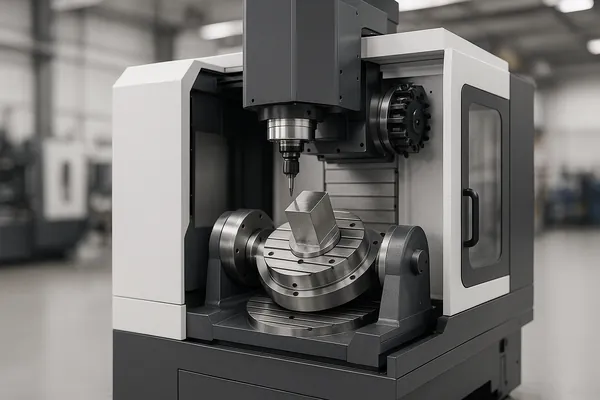

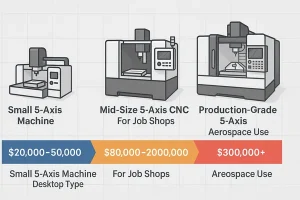

Understanding the Cost of a 5-Axis CNC Machine

The price of a 5 axis CNC machine can vary dramatically—from $20,000 for a desktop unit to well over $500,000 for a full-scale production system. Several factors influence this range, including machine size, control software, spindle type, and automation capabilities.

Visual chart showing desktop, compact, and industrial 5-axis CNC machine price brackets

If you’re comparing options, it’s important to distinguish between 5 axis CNC machine price (the sticker price) and the cost of a 5 axis CNC machine over time—including maintenance, tooling, and operator training. For smaller workshops, a small 5 axis CNC machine may offer the best balance between budget and capability.

Used systems are also available, and in some cases, the used 5 axis CNC machine for sale market can yield high-value machines at a significant discount—especially from trusted brands like Haas or Mazak.

What Are the Best 5-Axis CNC Machines?

With so many machines on the market, finding the best 5 axis CNC machine depends on your application, material types, and automation needs. Well-known manufacturers like Haas, Okuma, Makino, and Mazak provide reliable machines for both entry-level and advanced users.

For example, a Haas 5 axis milling machine is widely used in job shops for its balance of price and performance. Meanwhile, manufacturers offering 5 axis CNC machine for sale listings may include refurbished models or fully loaded systems with tool changers, probing systems, and CAM software bundles.

Exploring 5-Axis CNC Machining Services

If you’re not ready to invest in your own equipment, outsourcing to a professional 5 axis CNC machining service can be a cost-effective solution. These services provide access to advanced machines, experienced operators, and tight quality control—without the overhead of ownership.

Common use cases of 5-axis CNC machines, including turbine blades, implants, and engine components

For prototyping, low-volume production, or complex parts that require tight tolerances and multi-face machining, working with a 5 axis machining company is often the smart choice. Service providers typically offer flexible options, including CNC 5 axis machining for intricate geometries, simultaneous 5 axis machining for curved surfaces, or even 5 axis water jet cutting machine capabilities for specialty materials.

When choosing a provider, consider their experience, available equipment types (e.g., gantry, horizontal, vertical), and whether they offer additional processes like inspection, finishing, or CAM software integration. Many also support simultaneous 5 axis machining center operations, especially when handling aerospace or medical-grade components.

Search for local providers using terms like 5 axis machining near me or 5 axis machine shops near me—but always compare their machine list, tolerances, and sample work before placing an order.

See also our article on advanced toolpath strategies for 5-axis machining for cost-saving techniques.

Buying a 5-Axis CNC Machine: What to Look For

When you’re ready to purchase, understanding the differences between machine types—such as a 5 axis milling machine, a 5 axis vertical machining center, or a gantry-style unit—is crucial. Each configuration affects work envelope, accuracy, and price.

A small 5 axis CNC machine may be ideal for shops with limited space or budget, especially for precision parts and prototypes. On the other hand, a large 5 axis CNC machine or 5 axis horizontal machining center is better suited for production runs, heavy components, or aerospace-grade complexity.

Don’t forget to evaluate the machine’s CAM software compatibility, spindle power, table movement (tilting or rotary), and available tool changer options. Many brands now offer compact models with impressive features—ideal for job shops looking to expand.

If you’re considering alternatives, used 5 axis CNC machine for sale listings can also provide great value. Just ensure you verify the maintenance history, calibration data, and spindle hours. Whether buying new or used, factors like long-term support and parts availability make a big difference.

Search platforms often include categories like desktop 5 axis CNC machine, mini CNC 5 axis milling machine, or 5 axis CNC machine cost—giving insight into what’s available and how to budget effectively.

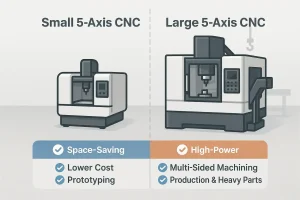

Comparing Small vs. Large 5-Axis CNC Machines

When deciding between a small 5 axis CNC machine and a large-scale 5 axis machining center, it’s important to consider more than just size. A desktop 5 axis CNC machine or mini CNC 5 axis milling machine is ideal for prototyping, research labs, or space-constrained workshops. These machines offer precision with minimal floor space, often at a lower investment cost.

On the other hand, a large 5 axis CNC machine provides greater work envelope and power, suitable for production machining of heavy-duty parts in aerospace, automotive, or oil and gas industries. Brands like Haas, Mazak, and DMG Mori offer both compact and industrial-scale 5 axis solutions to meet different needs.

Side-by-side visual comparison of a compact and an industrial-scale 5-axis CNC machine, highlighting size and application differences

How Your Application Influences Your Machine Choice

The parts you plan to machine will directly impact your purchasing decision. For example, industries like aerospace and medical manufacturing—which rely on intricate geometries and tight tolerances—often require high-end machines with advanced cooling systems and powerful spindles, which come at a higher cost. In contrast, smaller-scale prototyping or educational applications may only require a compact desktop unit with a lower price point. Understanding your specific application is the first step to evaluating the right machine for your needs.

Ready to Invest in 5-Axis Capabilities?

Whether you’re scaling up production or seeking tighter tolerances, investing in a 5 axis CNC machine can transform your machining capabilities. Evaluate your needs carefully—whether it’s a compact 5 axis CNC milling machine or a high-performance 5 axis machining center—and match them to your production goals and budget.

For job shops, consider whether 5 axis machining services offer a better return than ownership. If you’re already exploring machine quotes, be sure to compare 5 axis CNC machine price ranges, available tooling, and software support.

Need help choosing? Our experts can help you navigate specifications, pricing tiers, and service options. Contact us today to explore the best 5 axis CNC machine for your needs.

Looking for a structured overview of 5-axis machining principles, machine types, and design tips?

Check out our Complete 5-Axis CNC Machining Guide for more insights.