Why 5-Axis Toolpaths Require Unique Optimization

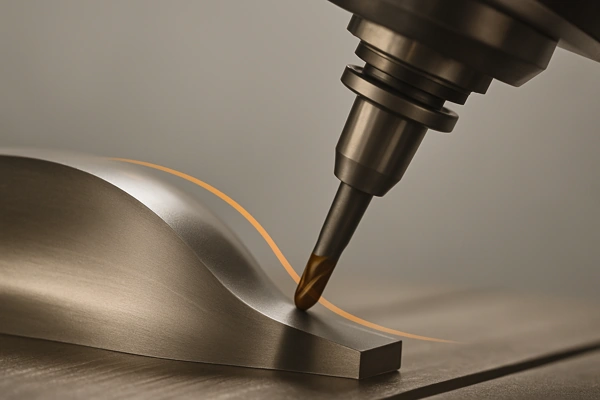

In 3-axis machining, tool movement is straightforward—linear across fixed axes. But with 5-axis CNC systems, the addition of rotary motion changes everything. Not only does the tool move in space, but its orientation constantly shifts in relation to the workpiece. That means any inefficiency in toolpath programming is multiplied across multiple axes.

This complexity introduces new challenges in motion control, collision avoidance, and surface consistency. Optimizing toolpaths in a 5-axis environment isn’t just about reducing cycle time; it’s about preserving machine longevity, minimizing errors, and ensuring consistent part quality.

This article builds on our comprehensive guide to 5-axis CNC machining by focusing specifically on toolpath optimization strategies.

Illustration showing how 5-axis toolpaths differ from 3-axis by enabling simultaneous motion and orientation changes.

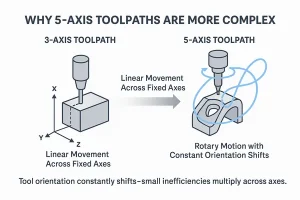

Typical Problems in Poorly Tuned 5-Axis Paths

Without proper optimization, 5-axis toolpaths can cause more harm than good. Some of the most common issues include:

- Excessive air cutting, where the tool is moving but not engaging material

- Sudden rotary axis movements, which increase mechanical wear

- Gouging or collisions, especially in undercuts or deep cavities

- Inconsistent surface finish caused by irregular feed rates or tool orientation shifts

These problems not only affect the quality of the machined part but also lead to unnecessary machine strain and wasted cycle time. They’re not always obvious until you encounter dimensional variation or finish defects in finished parts.

Diagram showing air cutting, gouging, and sudden tool orientation shifts in poorly optimized 5-axis toolpaths.

Strategies for Creating Smooth and Efficient Toolpaths

Effective 5-axis toolpaths balance machine motion with machining goals. One proven strategy is to minimize abrupt changes in tool orientation. This can be achieved by using continuous surface-based paths—such as morph or flowline strategies—which follow the part geometry more naturally.

Another key technique is smoothing transitions between tool vectors to reduce sudden rotational shifts. This not only improves surface finish but also minimizes load spikes on the rotary axes. Where possible, use the shortest tilt paths and maintain a consistent tool lead angle to reduce air time and axis acceleration.

By focusing on fluid motion and reducing unnecessary repositioning, you can increase overall cycle efficiency without sacrificing precision.

Side-by-side comparison of over-tilted and optimized tool orientations, showing how tilt angles affect tool reach and machining stability.

Optimizing Tilt Angles and Rotary Movements

One of the most powerful levers in 5-axis machining is controlling tilt angles. A slight adjustment in tool orientation—say, reducing a tilt from 30° to 10°—can significantly reduce tool wear and improve access to complex features. However, over-tilting may increase the chance of gouging or reach limitations.

Modern CAM systems allow you to define tilt limits, rotary axis speed caps, and even tool orientation blending curves. These settings help avoid extreme or jerky rotary motions that cause vibration and machine stress.

In critical areas like turbine blades or impellers, use controlled rotary axis movement to maintain a consistent engagement angle. This helps preserve tool integrity and ensures consistent surface contact throughout the pass.

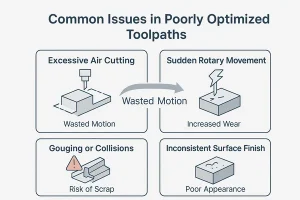

Reducing Air Cutting and Machine Idle Time

In 5-axis machining, it’s easy to underestimate how much time the tool spends moving without cutting. These “air cuts” often happen due to inefficient transitions between passes or suboptimal entry/exit strategies. Over time, they add up to longer cycle times and unnecessary machine wear.

To reduce air cutting, use strategies that maintain tool engagement for as much of the path as possible. Optimize retract heights, use shorter clearance distances, and adjust linking motions to follow part geometry more closely. Many CAM systems allow dynamic linking and auto-adjusted retracts—features that help keep the tool productive.

Reducing non-cutting motion not only boosts efficiency but also increases spindle utilization, delivering more value per machine hour.

Reducing unnecessary air cutting improves machining efficiency and tool utilization in 5-axis operations.

Managing Tool Deflection and Vibration

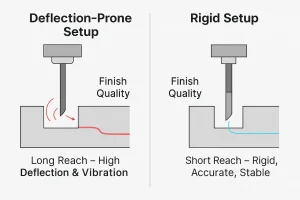

When dealing with deep pockets or long-reach features, tool deflection becomes a critical concern—especially in 5-axis setups where the tool may approach from less rigid angles. Deflection leads to dimensional inaccuracies, poor surface finish, and premature tool wear.

To control deflection, reduce stick-out lengths wherever possible and use optimized cutting parameters like lower radial engagement. High-rigidity toolholders and shorter tools also help minimize vibration. Additionally, toolpath strategies that maintain constant engagement—such as trochoidal motion or high-efficiency milling (HEM)—can reduce cutting forces significantly.

By proactively managing rigidity and tool dynamics, shops can achieve tighter tolerances and longer tool life in complex 5-axis jobs.

Improving Surface Finish in Complex Geometries

Achieving a fine surface finish in 5-axis machining depends heavily on how smoothly the tool transitions across curves and contours. Sharp changes in orientation or inconsistent stepovers can leave behind visible tool marks, especially on freeform surfaces like molds or aerospace components.

To improve finish, consider reducing the stepover distance in finishing passes and applying arc filtering to smooth motion transitions. Toolpath types like parallel to surface or morph between curves offer more controlled engagement, reducing ridges and mismatched passes. Additionally, using tools with larger corner radii can help blend transitions and minimize scallop marks.

A refined surface not only improves appearance but can also reduce or eliminate the need for secondary polishing or grinding processes.

Choosing the Right Toolpath Types for 5-Axis Jobs

Not all toolpaths are created equal, and in 5-axis machining, choosing the wrong strategy can lead to inefficiency or even failure. For example, swarf milling is ideal for machining tapered walls using the tool’s side, while contour milling is better suited for finishing steep features with the tool tip.

Visual comparison between a deflection-prone toolpath and a rigid setup that minimizes vibration and improves surface finish.

Morph toolpaths are excellent for flowing surfaces, maintaining consistent stepovers between boundaries. Flowline paths are preferred when machining turbine blades or impellers due to their directional consistency. Some CAM platforms also support hybrid paths, combining roughing and semi-finishing into a single continuous motion.

Selecting the right path type helps match tool motion to part geometry, which improves both efficiency and finish quality.

Balancing Automation and Manual Adjustment

Modern CAM software offers powerful automation features—automatic collision avoidance, adaptive feedrates, and tool orientation suggestions. But relying solely on these defaults can produce suboptimal results in critical areas.

Experienced programmers often fine-tune orientation vectors, override default transitions, or split toolpaths manually to achieve smoother motion. For parts with tight tolerances or hard-to-reach features, manual refinement ensures better control and precision.

The best results come from combining automation with expert judgment—use the software to generate a solid foundation, then apply your machining insight to elevate the toolpath quality.

Further Reading: Deepen Your 5-Axis Machining Knowledge

This article is part of our advanced 5-axis machining series.

Looking for a structured overview of 5-axis machining principles, machine types, and design tips?

Check out our Complete 5-Axis CNC Machining Guide for more insights.

Need help with 5-axis toolpath strategies or custom machining projects?

Contact our engineering team to discuss your needs or request a quote.