In today’s rapidly evolving manufacturing landscape, choosing the right production process is often more critical than the design itself. Whether you are developing a prototype for a new product or preparing for large-scale mass production, understanding the fundamental differences between “additive” and “subtractive” logic will directly determine your project’s cost and the performance of the final part.

This article explores the core logic of Additive Manufacturing and Subtractive Manufacturing, providing a clear selection guide through a multi-dimensional practical comparison.

What Is Additive Manufacturing?

To use a vivid metaphor, Additive Manufacturing is much like the process of “building a wall brick by brick.”

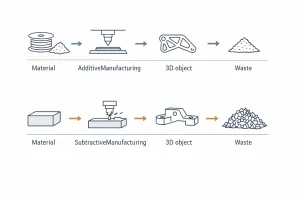

Commonly known as 3D printing, its core logic is “accumulation.” This process reads a CAD digital model and constructs complex three-dimensional solids from the bottom up by stacking, curing, or fusing raw materials—such as powders, liquid resins, or filaments—layer by layer.

Compared to traditional manufacturing, it completely breaks free from the constraints of cutting tool paths and molds. This “inside-out” construction method allows for the creation of extremely complex internal structures that were previously impossible to achieve.

Advantages of Additive Manufacturing

The greatest engineering value of Additive Manufacturing lies in its extreme design flexibility, ensuring that “complexity” is no longer expensive but a means of optimization.

- Infinite Design Freedom: It supports complex topology optimization and lattice structures, allowing for part consolidation to reduce weight and assembly steps.

- Minimal Material Waste: Material is only added where necessary. For expensive raw materials like titanium alloys, this “Near Net Shape” characteristic offers excellent economy.

- Rapid Response: No custom molds are required. Going directly from a digital design to a finished part makes it ideal for rapid prototyping and one-off customization.

Disadvantages of Additive Manufacturing

While Additive Manufacturing has changed the rules of design, it still faces trade-offs in industrial consistency and mass production efficiency.

- Limited Production Efficiency: The layer-by-layer physical process means long cycle times for individual parts, making it difficult to handle standardized orders in the tens of thousands.

- Surface Quality Requires Post-Processing: Printed parts often exhibit visible layer lines (staircase effect). Precise mating surfaces or aesthetic faces usually require fine grinding or polishing.

- Mechanical Anisotropy: Due to the layer-stacking nature, the strength in the vertical growth direction is often slightly weaker than in the horizontal plane.

What Is Subtractive Manufacturing?

Subtractive Manufacturing is more akin to “the art of sculpting,” representing the most mature and reliable cornerstone of the modern precision industry.

The logic of Subtractive Manufacturing is the opposite of additive: it starts with a solid block of raw material (a blank) and “cuts away” excess material through physical removal methods like milling, turning, or drilling to leave the desired shape.

This process is primarily executed by CNC (Computer Numerical Control) machines. The high-strength interaction between cutting tools and the raw material ensures extremely high dimensional stability and surface precision. As long as a tool can reach the area, Subtractive Manufacturing can produce high-quality components with incredible speed.

Advantages of Subtractive Manufacturing

Subtractive Manufacturing remains the gold standard in fields pursuing high strength, high precision, and standardized production.

- Extreme Precision Control: It easily achieves micron-level (μm) tolerances and mirror-like surface finishes, ensuring mechanical fits are perfectly tight.

- Mechanical Consistency: By machining directly from homogeneous blanks, the internal structure of the part remains uniform, stable, and exhibits isotropic properties.

- Broad Material Compatibility: It can process almost any hard material, from standard aluminum to super-hard stainless steels or high-temperature alloys.

Disadvantages of Subtractive Manufacturing

The bottlenecks of this process lie in the geometric constraints of its “subtractive” nature and its inherent inefficiency in material utilization.

- Severe Material Waste: The process generates significant swarf (chips). In complex part machining, material waste can sometimes exceed 80% of the original blank.

- Geometric Constraints: Tooling must have physical access to the workpiece. It is difficult to handle deep, narrow blind holes or extremely complex enclosed cavities.

- High Initial Cost Threshold: It involves complex programming, custom jig/fixture design, and tool wear, leading to high unit prices for small-batch production.

What’s the Difference Between Additive and Subtractive Manufacturing?

For quick reference during selection, we have conducted a side-by-side comparison of key performance metrics.

Tolerance and Accuracy

Subtractive manufacturing dominates the precision field. CNC machining can reliably hold tolerances of ±0.005mm. Additive manufacturing, affected by thermal expansion and material shrinkage, usually stays around ±0.1mm. Precise features often require additive parts to be “post-machined” by CNC to reach final specs.

Surface Finish

Subtractive Manufacturing is the natural winner for surface quality, capable of meeting functional or aesthetic requirements straight out of the machine. Additive parts are generally rougher with a grainy texture; for mating surfaces or high-end aesthetics, the cost of post-processing is a significant factor.

Geometry and Design Freedom

Additive Manufacturing is a designer’s playground, where “complexity” does not add cost. It is perfect for complex internal fluid channels and lightweight structures. Subtractive Manufacturing follows DFM (Design for Manufacturing) principles, where physical tool access is the primary constraint.

Materials and Mechanical Performance

Subtractive raw materials are dense and reliable. While Additive Manufacturing handles metals and plastics, the fusion between layers is a potential weak point; fatigue strength and pressure resistance are typically lower than those of machined parts from forged or rolled stock.

Cost and Lead Time

For 1–10 prototypes, Additive Manufacturing wins on lead time and price by eliminating tooling. However, as production volume increases (e.g., >1000 units), the automation speed of Subtractive Manufacturing quickly dilutes initial setup costs, making it highly cost-effective for mass production.

Post-Processing and Quality Control

Subtractive Manufacturing quality control is highly standardized. Additive Manufacturing is more tedious; besides support removal, heat treatment is often required to relieve stress. For critical parts, expensive industrial CT scans may be needed to detect internal porosities.

When to Choose Additive Manufacturing?

Additive manufacturing provides the highest value when innovation and speed outweigh the need for massive volume.

Complex Geometries and Lightweighting

When your part requires integrated internal cooling channels or topology optimization for aerospace weight reduction, Additive Manufacturing is the only solution. It optimizes internal lattice structures to drastically reduce weight without sacrificing strength.

Rapid Prototyping and Iteration

During early product development, time is more valuable than cost. If you need to verify multiple design versions in a short period, Additive Manufacturing provides physical parts from CAD in hours. This speed allows for rapid mitigation of design flaws.

Small Batches and Personalization

In medical fields for dental crowns or orthopedic implants, every product is unique. In this “high-mix, low-volume” market, Additive Manufacturing offers unrivaled cost flexibility by eliminating the need for expensive custom molds.

When to Choose Subtractive Manufacturing?

Traditional Subtractive Manufacturing remains the irreplaceable cornerstone for high-precision and high-volume industrial requirements.

Precision and Tight Tolerances

If your part belongs to a precision mechanical system (e.g., bearing seats, gears, high-pressure valves), the micron-level stable tolerances provided by Subtractive Manufacturing are the baseline for reliability. It is the best choice for industrial precision fits.

Superior Material Strength

For aero-engine blades or heavy structural components subjected to extreme cyclic loads, parts machined from homogeneous stock provide the most predictable failure models. Its isotropic properties ensure consistent strength in all directions.

Medium to Large Scale Production

Once a design is finalized and enters the scale of tens of thousands of units, CNC automated machining centers are unbeatable in speed and unit cost. Its high consistency and repeatability are key to scaling effectively.

Conclusion

Additive and Subtractive manufacturing are not rivals but complementary tools in an engineer’s toolkit. Additive represents “Freedom of Innovation,” while Subtractive represents “The Benchmark of Precision.”

The current industrial trend is shifting toward “Hybrid Manufacturing”—using additive processes to create complex near-net-shape blanks, followed by subtractive processes for precision finishing of critical mating surfaces. Mastering the boundaries of both is the only way to achieve the optimal balance between performance and cost in project management.

Would you like a more specific cost analysis for your next manufacturing project? Contact our engineering consulting team for professional technical support and a custom quote.