In B2B manufacturing, when engineers ask about color, the answer is far more complex than just a swatch. Color is an engineering parameter defined by performance, durability, and cost-effectiveness. This guide analyzes the color spectrum, technical boundaries, and restrictions of Type I, Type II, and Type III anodizing to help engineers and procurement specialists make the most reliable color decisions.

Coloring Principles and Technology

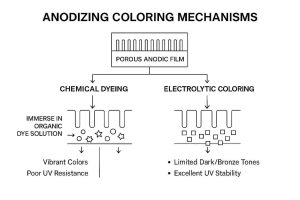

The porous structure of the anodic film is fundamental to successful coloring. The aluminum oxide layer created during the electrochemical process has tiny pores that can absorb either dyes or metal ions.

Dyeing Technology Comparison

- Chemical Dyeing (Organic Dyes): The film absorbs an organic dye solution. While colors are vibrant and diverse, they have poor UV resistance and weather fastness, making them ideal only for indoor or non-critical cosmetic applications.

- Electrolytic Coloring (Inorganic Metal Salts): Metal salts are deposited into the film’s pores. The color range is limited (typically black, bronze), but the finish offers superior lightfastness and weather resistance, making it mandatory for outdoor and architectural applications.

Color and Sealing Quality

The only guarantee for long-term color durability is sealing. The sealing process converts the porous structure into an inert, crystalline compound, effectively isolating the coating from the environment. Unsealed or poorly sealed colors, regardless of the dye used, will quickly fade due to UV exposure or the absorption of environmental contaminants.

Alloy and Color Deviation

Choosing a color begins with understanding the aluminum alloy’s compatibility, as the alloy type dictates the final outcome.

Alloy’s Impact on Color

Impurities in aluminum alloys (especially silicon (Si) and copper (Cu)) negatively affect the pore structure and transparency of the oxide film. This results in subtle color differences or inconsistencies even when the same dye is used.

Color Deviation Risks

- Ideal Alloys: 6061 and 7075 series aluminum typically yield the best color consistency and clarity.

- Risk Alloys: Alloys with high silicon content (e.g., cast alloys like 3xx series) or high copper content are unsuitable for coloring, often resulting in dull, gray, or blotchy finishes.

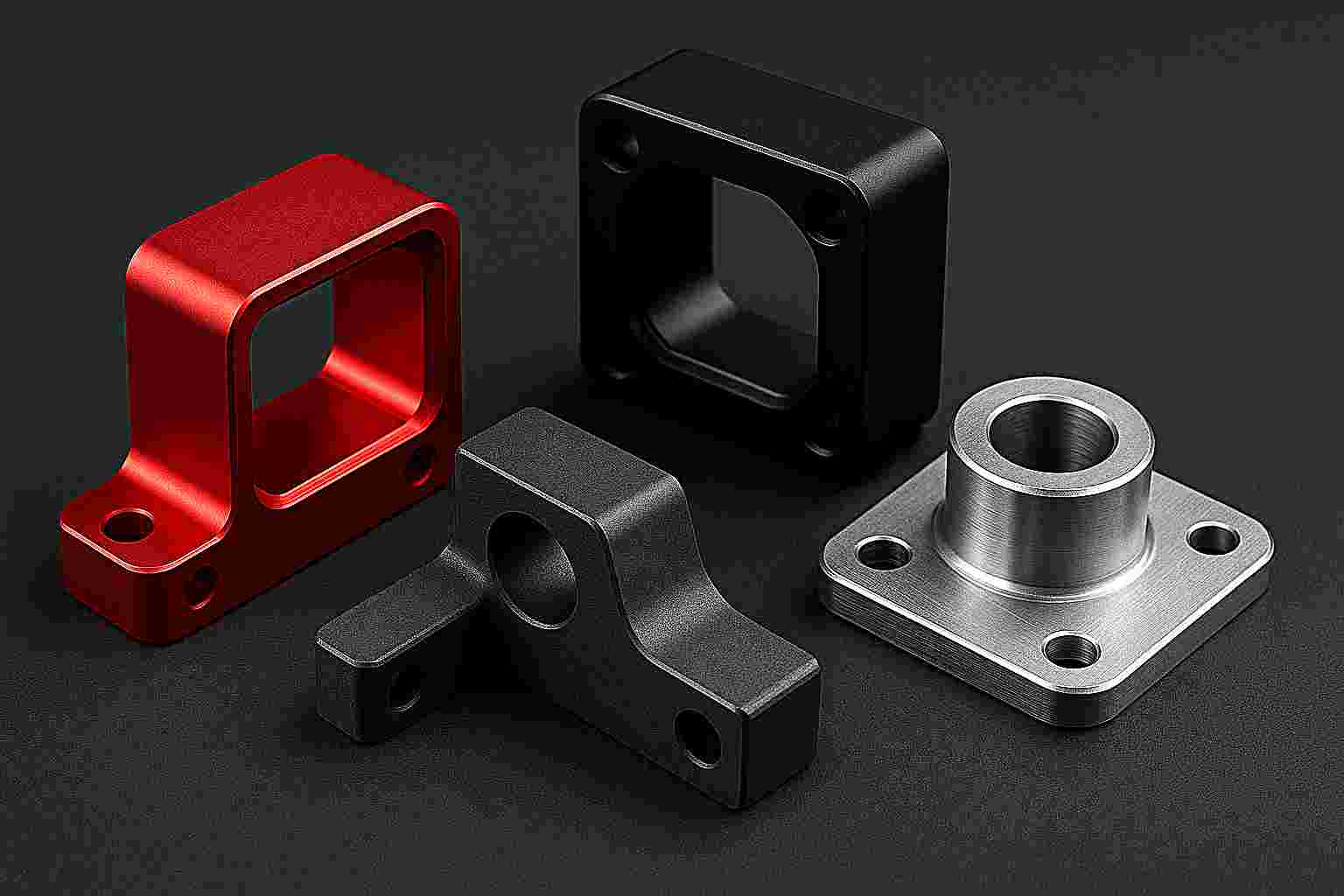

Color Types and Ranges

Color availability is intrinsically linked to the coating’s thickness, porosity, and density. The following sections provide an engineering breakdown based on the MIL-A-8625 standard:

A. Type I (Chromic): Thinnest Coating with Color Restrictions

- Technical Profile: The thinnest coating ($\text{0.5-2.5 \mu m}$) with minimal porosity.

- Color Range: The natural color is clear to faint gray/green. The film is not easily dyed and is typically left undyed.

- Core Applications: Aerospace parts (especially those requiring tight tolerance fits), welded assemblies, and use as a pretreatment before painting.

B. Type II (Sulfuric): Standard Thickness and Maximum Color Range

- Technical Profile: Medium thickness with uniform porosity, making it the most suitable for dyeing.

- Color Range:

- High Stability Functional Colors: Clear/Silver and Black (best UV resistance).

- Decorative Standard Colors: Red, Blue, Gold, Green, Violet, and other vibrant colors.

- Color Challenge: Pure white is technically unachievable.

- Core Applications: Consumer electronics enclosures, household fixtures, architectural trim, and all parts requiring a moderate durability with aesthetic color.

C. Type III (Hardcoat): High Hardness with Deep Color Functional Limits

- Technical Profile: The thickest coating ($\text{25-150 \mu m}$), offering the highest hardness (350-500 HV). The natural oxide color is dark gray.

- Color Range:

- Standard Functional Colors: Natural dark gray/brown-gray.

- Optional Functional Colors: Black and Military Green.

- Color Restriction: Type III cannot achieve bright or light colors because the coating’s naturally dark foundation masks lighter dyes.

- Core Applications: Mechanical sliding components (e.g., pistons, valves), high-friction bearings, and industrial equipment requiring extreme abrasion resistance and high insulation.

Frequently Asked Questions (FAQ)

Q: What colors are available for Type III Anodizing?

A: The color range is very limited. Primarily, you can choose the natural deep gray/brown-gray or black. Type III cannot be successfully dyed into bright or light colors.

Q: Does anodizing color fade over time?

A: Yes, it can. This depends entirely on the dyeing technology and the quality of the sealing. Organically dyed Type II colors will fade when exposed to UV light. Electrolitically colored finishes are highly stable.

Q: Can anodizing be done in pure white?

A: No. The anodized film is a porous, translucent aluminum oxide structure. It can only absorb color; it cannot be dyed to create an opaque pure white finish.

Q: Do different aluminum alloys affect the same color?

A: Yes. Impurities like silicon and copper within the alloy can cause subtle color variations or unevenness in the final finish, even when using the identical dye process.

Q: Can you change the color of anodized aluminum?

A: Yes, but the old layer must first be removed via chemical stripping. The part must then be re-anodized and re-dyed from scratch. Be aware: The stripping process dissolves some of the base metal, which may cause loss of dimensional tolerance on precision parts.

VI. Anodizing vs. Alternative Coloring Methods

When considering coloring solutions for aluminum, several primary options exist: anodizing, powder coating, and liquid painting. The choice depends heavily on the project’s specific requirements and expected finished performance.

| Feature | Anodizing (Type II/III) | Powder Coating | Liquid Paint |

| Color Range | Limited (No pure white; dictated by chemistry). | Unlimited (Any RAL/Pantone, textures). | Unlimited (Requires solvents; often high VOC). |

| Durability | Moderate to Excellent (Type III highly superior). | Excellent (Good UV resistance, flexible). | Poor (Prone to chipping and flaking). |

| Retained Look | Retains Metallic Texture (Integrated film). | Covers Completely (Plasticized finish). | Covers. |

| Hardness/Abrasion | Extremely High (Type III is unmatched). | Good (Suitable for low-to-moderate friction). | Low. |

| Coating Thickness | Thin ($\text{5-150 \mu m}$), minimal tolerance impact. | Thick ($\text{50-200 \mu m}$), impacts dimensional tolerance. | Thin to Moderate. |

Conclusion

Successful anodizing color selection is a critical balance between engineering requirement and aesthetic appeal. By understanding the color boundaries of Type I, II, and III, and recognizing the decisive role that alloy and sealing play in long-term durability, you can ensure your product meets visual standards while delivering the required long-term performance. Successful color customization depends on a thorough grasp of these technical details.

Contact Our Engineering Team

Are you facing challenges with color consistency for hardcoat anodizing? Or do you need to verify your specific alloy’s compatibility with a custom color? Contact our engineering team. We provide alloy compatibility testing, film thickness analysis, and customized coloring solutions to ensure your final color choice is both aesthetically pleasing and compliant with the most stringent performance standards.

Click here to discuss your custom color engineering needs with our experts.