Bead blasting is a surface finishing process used to unify the texture and visual appearance of machined metal parts. By propelling fine spherical media toward the surface, machining marks and directional reflectivity are softened, resulting in a smooth, uniform, low-gloss matte finish. It visually stabilizes surfaces while preserving dimensional accuracy and edge definition. This article explains what bead blasting is, how it works, the equipment involved, media selection, differences from abrasive blasting, typical engineering applications, and best practices for consistent mass production.

What Is Bead Blasting

Bead blasting improves the uniformity of a metal surface by applying spherical media that gently peen micro-peaks rather than cut material. Unlike polishing or brushing, which rely on material removal or directional abrasion, bead blasting produces a neutral, non-directional matte appearance. The underlying geometry, sharp edges, chamfers, and precision dimensions are maintained while the visible surface becomes more even and refined.

How Bead Blasting Works

The process typically involves four sequential stages: cleaning, masking, blasting, and post-cleaning. Parts are first thoroughly degreased to avoid stain patterns or media contamination. Areas that must not be affected—such as sealing surfaces, mating faces, threads, and datum edges—are precisely masked.

The Blasting Mechanics

During the blasting stage, the process transforms the surface via micro-peening. The nozzle is held at controlled distances and angles while the operator or automation system moves across the part in a smooth, overlapping cross-hatch pattern. Key parameters that dictate the final outcome include:

- Impact Pressure: Typically controlled between $0.3\text{–}0.7 \text{ MPa}$, this pressure determines the kinetic energy of the media, directly influencing the intensity of the peening action and the final Roughness Average ($R_a$).

- Angle of Attack: Holding the nozzle perpendicular (90°) to the surface is often ideal to ensure uniform coverage and minimize directional texture. Deviations from this angle can lead to streaking.

- Stand-off Distance: A controlled distance optimizes the media spray cone coverage; too close creates intense hot spots, while too far reduces efficiency.

The media impacts the surface and redistributes micro-height variation, causing a localized plastic deformation that converts specular (mirror-like) reflection into diffuse reflection, resulting in the smooth, low-gloss matte finish. After blasting, residual media and dust are removed via vacuum or air washing, and the part is dried to maintain visual clarity and process stability.

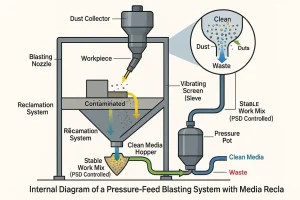

Tools Used for Bead Blasting

Bead blasting relies on controlled tooling to achieve a consistent, uniform matte finish. The following equipment influences surface texture, coverage stability, and repeatability across batches.

Blasting Nozzle

The blasting nozzle accelerates the media and defines the impact pattern on the surface. Nozzles made of carbide or boron carbide resist wear, helping maintain a stable spray geometry. Consistent nozzle angle, stand-off distance, and smooth cross-hatch movement are critical to avoiding streaks, shadowing, or localized roughness.

Blasting Cabinet

The blasting cabinet provides a controlled working environment and manages clean media circulation. A clear viewing window, internal lighting, and adjustable or rotating fixtures support visibility and uniform coverage, especially for multi-surface or geometrically complex parts.

Workholding and Rotating Fixtures

Workholding tools ensure that the part remains stable and properly oriented during blasting. Rotating or tilting fixtures help the operator apply consistent spray patterns and reach recessed features, internal radii, or multi-face surfaces without over-processing any area.

Masking Materials

Masking protects critical dimensions and functional surfaces that must not be altered. Common masking tools include tape, plugs, caps, and precision-cut shielding films. These prevent micro-peening on sealing faces, mating areas, sharp edges, and tolerance-controlled datums.

Operator Protective Gear

Protective gloves, arm sleeves, safety glasses, and dust control garments protect the operator from rebounding media. Ensuring ergonomic access and safe visual control helps maintain stable, repeatable motion during blasting.

Media Types and Selection

Media form, hardness, and size dictate finish texture, reflectivity, and dimensional safety. The choice depends critically on whether the priority is cosmetic appearance, enhancing coating adhesion, or protecting tight tolerances on the machined part.

Glass Bead

Glass beads are spherical, chemically inert media that provide a smooth, soft matte texture via a peening (impacting) action rather than an abrasive (cutting) action.

- Mechanism & Finish: They are ideal for cosmetic surfaces, particularly on aluminum enclosures, precision housings, and consumer products. They soften machining marks and directional reflectivity, resulting in a uniform, low-gloss finish with a lightly silky touch.

- Hardness & Safety: Glass beads are relatively low on the Mohs hardness scale (around 5.5 to 6.5). This softness makes them dimensionally safe for most precision parts, ensuring minimal material removal.

- Limitation: Due to repeated impacts, glass beads break down faster than ceramic media, necessitating more frequent replenishment and closer monitoring of the Work Mix to maintain batch consistency.

Ceramic Bead

Ceramic beads are the premium spherical media, typically made from zirconium-based compounds. They offer superior durability and tighter size classification compared to glass beads.

- Mechanism & Finish: Their high hardness and low breakdown rate (meaning greater shape stability) produce tighter, more consistent grain patterns and superior batch-to-batch repeatability. This is critical for sectors like medical instrumentation, aerospace structures, and high-end branded components that demand controlled, repeatable finish levels ($R_a$ values).

- Hardness & Lifetime: Ceramic beads are significantly harder (often Mohs 7.5 to 8.0) and much more expensive than glass, but their extended operational life often makes them more cost-effective in high-volume or highly-demanding applications.

- Performance: They deliver a finish that can range from a fine, sharp matte to a smooth satin, depending on the pressure and bead size (mesh).

Aluminum Oxide

Aluminum Oxide (Alumina) is a sharp, angular, and highly aggressive abrasive, classified as a cutting medium rather than a peening medium.

- Mechanism & Function: It raises surface energy through micro-cutting and roughening the substrate. This creates a deeply keyed profile (high $R_a$ value) that is essential for mechanical interlocking with subsequent coatings.

- Primary Application: It is the gold standard pre-treatment before processes like anodizing, powder coating, PVD, or electroplating to maximize adhesion and longevity of the coating.

- Grade & Hardness: It is very hard (Mohs 9.0), quickly removing scale, rust, and heavy machining layers. Different mesh sizes (e.g., 60-grit for aggressive cuts, 120-grit for finer preparation) are selected based on the required surface profile (anchor pattern) depth. Note: Aluminum oxide leaves an industrial, grainy appearance and must be followed by a lighter bead pass if a soft cosmetic finish is still required.

Polymer and Natural Media

These are the softest, lowest-impact media designed for tasks where dimensional integrity and material preservation are the absolute priority.

Benefit: They are primarily used to remove light contamination, flashing, or unify surface texture without inducing stress or altering the underlying geometry. They are often the safest choice for cleaning molds or delicate instrumentation.

Mechanism & Types: This category includes engineered polymer media (e.g., nylon, acrylic) and natural media (e.g., walnut shells, corn cobs). They clean and unify surfaces by light wiping and micro-adjustment rather than cutting or heavy peening.

Primary Application: They are crucial for thin-wall parts, highly toleranced features (e.g., sealing faces, threads), or sensitive materials (like soft plastics or certain composites) where any material removal or surface stress is unacceptable.

Microscopic view of blasting media: Glass and Ceramic beads (spherical, for peening) versus Aluminum Oxide and Polymer/Natural media (angular/soft).

Bead Blasting vs Abrasive Blasting

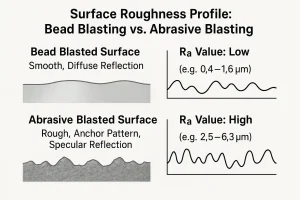

While both processes leverage high-velocity media impact, their primary goals and resulting surface states are fundamentally different. The distinction lies in the geometry of the media and the kinetic energy applied.

Mechanism and Energy

Bead blasting utilizes spherical, lower-density media (such as glass or ceramic beads) propelled at controlled, generally lower pressures. The process imparts kinetic energy to the surface, reforming the micro-peaks left by machining without significant material removal. This action effectively minimizes surface stress. In contrast, abrasive blasting employs angular, higher-density media (such as aluminum oxide or silicon carbide) at higher pressures, which aggressively cuts and fractures the existing surface structure, resulting in material loss.

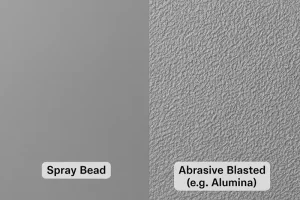

Appearance and Texture

Bead blasting consistently yields a soft, fine, non-directional matte finish. This texture is highly desirable for cosmetic and consumer product enclosures where diffused light reflection is required. Abrasive blasting produces a rougher, visibly grainier, more industrial texture with a much higher Roughness Average ($R_a$). This dramatic increase in surface area is characterized by an angular, pitted profile known as an anchor pattern—essential for mechanical bonding.

Dimensional and Edge Retention

Bead blasting is considered dimensionally benign. Since the process involves micro-peening rather than cutting, it effectively preserves sharp edges, critical chamfers, and tight dimensional tolerances. Abrasive blasting, due to its aggressive, material-removing nature, carries a significant risk of rapidly softening or rounding critical edges and causing measurable dimensional change if not strictly controlled via masking or automated movement.

Use Case Orientation

Bead blasting serves predominantly as a final cosmetic finishing step, ideal for aluminum, stainless steel, or titanium parts that will be visible or handled. Abrasive blasting is defined as a necessary pre-treatment stage before applying subsequent finishes. Its sole purpose is to increase the surface area and mechanical keying ability required for robust adhesion and longevity of processes like powder coating, anodizing, painting, or PVD/Electroplating.

Advantages and Limitations

Understanding the inherent strengths and weaknesses of bead blasting is vital for determining its appropriate use in a mass production pipeline.

Key Advantages

Bead blasting offers specific benefits that make it superior to aggressive abrasive methods for precision machined parts:

- Uniform Matte Surfaces & Aesthetics: Provides a consistent, non-directional matte or satin finish by peening the surface. This is highly valued in the medical, food, and mechanical engineering sectors for a clean, refined, and glare-reducing look.

- Minimal Dimensional Impact: The process uses spherical media at lower pressure, ensuring it does not damage or distort delicate materials (like aluminum or thin-walled alloys) and maintains dimensional accuracy without significant material removal.

- Enhanced Surface Performance: The impact action can induce a shallow layer of compressive residual stress (peening effect), which helps increase fatigue life and relieve tensile stresses introduced during machining.

- Safety and Environmental Profile: Glass and ceramic beads are often lead-free and chemically inert, producing less dust and debris compared to sandblasting, contributing to a cleaner, safer operation with higher media reusability.

Process Limitations

To avoid costly rework, engineering teams must be aware of the inherent boundaries of the process:

- Ineffective on Heavy Scale/Rust: Bead blasting is less aggressive than grit or shot blasting and cannot cope with thick rust, heavy mill scale, or hard oxide layers. These require a sharp cutting abrasive (like Aluminum Oxide) as a precursor.

- Not Ideal for Paint Adhesion Profile: The smooth, peened finish does not create the deep anchor pattern (high $R_a$) required for optimal mechanical bonding of thick coatings like paint or powder. This limits its use where rough surface activation is the priority.

- Risk of Media Embedding: Using excessively high pressure or improper technique can cause glass beads to embed on the component’s surface, which can contaminate subsequent chemical processes (like anodizing) or affect the long-term performance of critical internal engine parts.

- Higher Initial Cost: The finer glass and ceramic beads are typically more expensive than traditional sand or crushed grit, making the process generally more costly for large-area, rough stripping tasks.

Typical Engineering Applications

Bead blasting’s unique ability to refine surface appearance without compromising precision makes it indispensable across several high-tech and consumer sectors.

Cosmetic Finishing: The process is the preferred choice for achieving the signature uniform satin finish on aluminum housings, precision enclosures, and stainless steel components used in high-end consumer electronics and appliances to reduce glare and improve visual consistency.

Preparation for Chemical Finishes: It is routinely used as a gentle final preparatory step before processes that are sensitive to surface roughness:

- Anodizing: Provides a uniform, non-directional base texture that eliminates streak patterns and ensures consistent color absorption of dye.

- Electroplating/PVD: Cleans and stabilizes the surface for uniform thickness and enhanced adhesion of thin-film coatings.

High-Consistency and Delicate Materials: The controlled, non-abrasive nature is critical in industries with stringent requirements:

- Medical and Food Industry: Applied to surgical instruments, implants, and food-grade stainless steel to create a smooth, cleanable, non-reflective surface (Source 1.4).

- Aerospace Alloys: Ideal for treating high-strength aerospace alloys like titanium and Inconel and on thin-walled parts (thickness $<1\text{ mm}$) where material removal or plastic deformation must be minimized (Source 1.7).

- Functional Enhancement: Used in specialized applications (like gear tooth surfaces or 3D printed parts) to achieve surface cleaning plus compressive stress strengthening, improving fatigue life (Source 1.7).

Best Practices for Consistent Mass Production

Adhering to strict best practices is essential for achieving the required visual and functional consistency across high volumes of machined parts. Deviations in control parameters are the primary cause of surface defects.

Clean the Part Prior to Blasting Contaminants cause shadowing and inconsistent color response—this is particularly true for parts that will be anodized or coated afterward. Ensure thorough degreasing and drying using industrial cleaning methods (such as ultrasonic cleaning or vapor degreasing) to remove all oils, coolants, fingerprints, or cutting fluids. Any residual contaminant can polymerize under the heat of friction, resulting in permanent, undesirable stain patterns or localized shiny spots on the finished surface.

Keep Nozzle Angle and Distance Constant Stable geometry of movement ensures texture continuity and avoids streaking or “hot spots.” The nozzle should typically be held perpendicular to the surface (at a 90-degree angle) for the most uniform effect, or slightly offset (e.g., 75–85 degrees) depending on the part geometry. Automated robotic blasting systems are the ideal solution for maintaining this stability across complex parts, eliminating the inconsistencies caused by operator fatigue or manual technique.

Control Media Breakdown and Work Mix Media gradually wears smaller or breaks down into dust through repeated impact. This breakdown must be managed to preserve the required finish level. Define regular replacement and screening intervals to maintain a stable Particle Size Distribution (PSD)—or Work Mix—within the machine. If the media wears too small, the finish will become too glossy; if too large, the texture will be too rough. The recovery system must efficiently remove fines and dust while adding new, correctly sized media.

Mask Critical Functional Surfaces Masking protects areas where material removal or surface alteration is unacceptable. Sealing faces, precision threaded holes, bearing bores, toleranced interfaces, and datum edges may need reduced intensity or total masking protection. Use high-quality, durable materials, such as resistant tapes, custom silicone plugs, or specialized coatings, to ensure the masking survives the intense kinetic impact of the blasting process without failing or tearing.

Conclusion

Bead blasting stands as a highly effective and essential finishing process for precision machined components. It delivers a stable, repeatable, and visually unified matte finish while actively preserving critical dimensional accuracy and edge definition. Furthermore, the process prepares the component surface for high-performance downstream finishes, ensuring optimal adhesion and longevity for coatings such as anodizing, painting, and PVD.

Upload your drawing for a fast manufacturability review and recommended blasting parameters.