In modern industrial manufacturing, anodizing is one of the most widely used surface treatment processes for aluminum alloys. This electrochemical method creates a dense, hard oxide layer on the surface of the aluminum. When this layer is dyed a deep black, it not only enhances the visual texture of the part but also provides a significant boost in performance.

What is Black Anodizing?

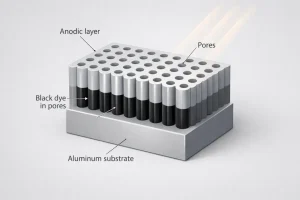

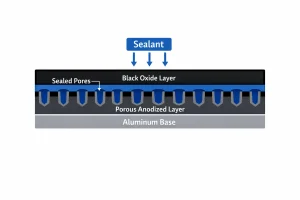

Black anodizing is not simply a surface coating; it is a controlled electrochemical conversion process. By applying an electric current in an acidic electrolyte bath, a microscopic porous layer of aluminum oxide is grown on the surface of the aluminum alloy. Black dye is then absorbed into these pores, and a final sealing process locks the color deep within the metal surface. This method integrates the color into the material itself, ensuring it will not peel or flake like traditional paint.

To understand why this process is so highly regarded in industrial manufacturing, we must look at the functional advantages it provides to components.

Advantages of Black Anodized Aluminum

Black anodizing does more than just change the appearance of the metal; it provides a significant leap in hardness, protection, and optical performance for aluminum alloys through the following key characteristics:

Wear Resistance and Hardness

The oxide layer is essentially aluminum oxide, which is much harder than the base aluminum alloy. This makes the black anodized aluminum surface highly resistant to scratches and physical wear during daily use, significantly extending the service life of parts in high-friction environments.

Corrosion Resistance

This dense oxide film acts as a physical barrier between the metal and the external environment. It blocks oxygen and moisture from corroding the aluminum substrate, allowing black anodized aluminum to remain structurally stable even in humid or chemically aggressive conditions.

Heat Dissipation and Light Absorption

Black surfaces have a high thermal emissivity, helping electronic heat sinks radiate heat more efficiently. Additionally, the deep black finish absorbs the vast majority of visible light, eliminating reflective interference—a feature that is vital for precision optical instruments.

Limitations of Black Anodized Aluminum

While black anodized aluminum is widely used in industry, it is not a perfect solution for every environment. Before deciding on this process, it is essential to understand the technical limitations inherent to this specific surface treatment:

UV Resistance

Most black anodized aluminum processes utilize organic dyes to achieve a deep, uniform color. Under prolonged exposure to intense ultraviolet (UV) light, these dye molecules can degrade, causing the black finish to fade or shift toward dark gray or purple. For components used outdoors long-term, specialized inorganic metal salt dyeing is often required.

Chemical Resistance

The oxide layer on black anodized aluminum is primarily composed of alumina. While stable in neutral environments, it is susceptible to chemical dissolution in strongly acidic or alkaline conditions, typically outside the pH range of 4.0 to 8.5. This can lead to coating failure, color loss, and substrate corrosion.

Thermal Stability

The coefficient of linear expansion for the aluminum oxide layer is significantly lower than that of the aluminum substrate. When black anodized aluminum parts are exposed to temperatures exceeding 80°C, the mismatch in thermal expansion can cause the oxide layer to develop microscopic cracks, known as crazing. While this may not affect overall corrosion protection, it can compromise the visual integrity of the surface.

Electrical Conductivity

Black anodized aluminum is an excellent electrical insulator. This means that if specific areas of a part require EMI shielding or electrical grounding, those sections must be precisely masked before the anodizing process or machined afterward to remove the insulating film, which increases production costs and complexity.

Materials Required for Black Anodizing

Achieving high-quality black anodizing requires not only the core aluminum substrate but also a range of precisely formulated chemical agents and specialized equipment.

Aluminum Alloy Substrate

As the primary material, the composition of the aluminum alloy directly affects the quality of the oxide film. While most aluminum alloys can be anodized, the 5000, 6000, and 7000 series typically yield more uniform results due to their lower impurity levels. Since the original surface condition (such as extrusion marks or scratches) is amplified after anodizing, high-quality raw material is essential.

Electrolyte and Chemical Additives

The process involves various chemical media. The core is the dilute sulfuric acid electrolyte used to grow the oxide layer. Additionally, degreasers and alkaline etchants (usually sodium hydroxide) are required for pre-treatment, along with desmutting agents for neutralization. The concentration and purity of each chemical must be strictly controlled to prevent film contamination.

Black Dyes and Sealing Agents

The dye is the key factor determining color depth, typically utilizing specialized organic black dyes or inorganic metal salts. Once dyeing is complete, sealing agents (such as nickel acetate or heated deionized water) are used to close the microscopic pores through physical or chemical reactions. These materials determine the final colorfastness and weather resistance of the part.

How to Perform Black Anodizing on Aluminum

From raw aluminum to the final finished part, every stage of the process directly determines the adhesion, durability, and color consistency of the coating.

Surface Pre-treatment

Before anodizing, parts must undergo degreasing and etching to remove surface impurities. The physical treatment chosen at this stage determines the visual texture: bead blasting creates a subtle matte finish, while polishing results in a high-gloss, mirror-like appearance.

Anodizing and Dyeing

The aluminum parts are submerged in an electrolyte bath and energized to form a uniform porous structure on the surface. Next, the parts enter a dyeing tank where black dye molecules penetrate the pores through capillary action. Technicians must precisely control the tank parameters to ensure a deep black color without variation.

Sealing Treatment

This is the critical final step in the process. Through hot water or chemical sealing, the pores in the oxide film are constricted and closed, permanently locking the dye inside. High-quality sealing significantly enhances stain resistance and prevents the color from fading over time.

Because of these versatile and durable properties, black anodized aluminum has become a standard in many high-tech industries.

Considerations for Black Anodizing

While black anodizing significantly enhances part performance, there are several key technical factors that designers and engineers must weigh before moving into production.

Selection of Aluminum Alloy Grades

Different series of aluminum alloys react differently to the anodizing process. For instance, the 6000 and 7000 series (such as 6061 or 7075) typically yield a very uniform and deep black finish. In contrast, cast aluminum or alloys with high silicon content may appear grayish or exhibit uneven textures after anodizing; therefore, the raw material must be chosen carefully based on the final aesthetic requirements.

Dimensional Tolerance Control

The anodizing process grows an oxide layer on the surface, which typically causes a slight increase in the dimensions of the part. For precision-fit mechanical components, it is essential to account for this added thickness (usually ranging from a few micrometers to tens of micrometers per side) during the machining stage to ensure accuracy during final assembly.

Color Variation and Batch Consistency

Because anodizing is influenced by variables such as current density, bath temperature, and immersion time, slight color variations can occur between different batches. For large-scale production or projects involving multiple interlocking parts, it is advisable to use raw materials from the same lot and process them under identical parameters to ensure maximum visual consistency.

Managing these technical details is crucial for the final yield rate, and proper pre-processing foresight helps ensure stable performance in subsequent application scenarios.

Common Application Scenarios

From precision optical components to high-strength aerospace structures, the use of black anodized aluminum covers almost every field where quality and performance are critical.

Optical and Precision Instruments

Because this process provides excellent light-absorbing properties, it is widely used in camera lens barrels, telescope internals, and laser sensor housings to ensure that stray light does not interfere with image quality.

Electronics and Semiconductor Equipment

In high-end consumer electronics, machine controllers, and cooling modules, the black oxide layer provides both reliable electrical insulation and the sleek industrial aesthetic required by modern design.

Aerospace and Automotive Industries

For lightweight parts that require high weather resistance, such as dashboard brackets and high-performance engine components, black anodizing offers a surface solution that is both light and exceptionally durable.

Differences Between Black Anodizing and Powder Coating

Black anodizing and black powder coating are two distinct surface finishing solutions. Understanding their differences in bonding methods and physical properties is crucial for selecting the right process.

Bonding Method and Structure

Anodizing is an electrochemical conversion process that grows an aluminum oxide layer directly from the substrate, integrating the color into the metal. Powder coating is a physical application where plastic resin is electrostatically sprayed and cured onto the surface. Consequently, anodizing eliminates the risk of peeling or flaking, whereas powder coatings may chip under extreme impact.

Coating Thickness and Precision

The anodized layer is extremely thin and uniform, typically ranging from 5 to 25 microns, having minimal impact on tight dimensional tolerances. In contrast, powder coating is much thicker, usually between 60 to 120+ microns, and tends to build up on edges and in holes. For precision-fit mechanical components, anodizing is the superior choice.

Visual Texture and Detail Retention

Since the anodized film is a translucent oxide layer that absorbs dye, it preserves and enhances the natural metallic texture and machining marks (such as brushing or sandblasting). Powder coating is an opaque, thick layer that tends to obscure fine surface features, resulting in a finish more akin to plastic or heavy paint.

Frequently Asked Questions

Professional answers to common concerns regarding black anodizing:

Is black anodized aluminum prone to scratching?

The anodized layer possesses exceptional hardness (typically 200-500 HV), making its wear resistance far superior to raw aluminum. While it resists everyday scuffs well, it can be scratched by high-force contact with harder materials like carbides or sand, which may reveal the silver aluminum underneath.

What is the cost of black anodizing?

The cost is generally considered moderate. Pricing is primarily influenced by the geometric complexity of the part (racking requirements), batch size (rack density), and the specified precision for film thickness and color consistency. While highly cost-effective compared to multi-layer liquid painting, it may carry a higher per-unit cost than high-volume, simple powder coating.

Is the process safe for health?

Finished black anodized products are non-toxic and chemically stable. The aluminum oxide layer is inert, and modern sealing processes generally comply with environmental standards like RoHS. It is safely used in cookware, medical devices, and consumer electronics with no known health risks from daily contact.

Can the color of anodized aluminum be changed?

Once the sealing process is complete, the color is permanently locked and cannot be directly changed. To switch colors, the existing oxide layer must be chemically stripped, which consumes a small amount of the aluminum substrate and alters dimensions. Therefore, it is recommended to finalize the color before production.

Conclusion

Black anodizing is more than just a decorative choice; it is a critical engineering process that balances functional requirements with visual appeal. Through a scientific electrochemical workflow, it allows aluminum alloys to remain lightweight while gaining the hardness and protection needed to withstand harsh environments. Whether for improving durability or achieving a premium industrial look, this process provides essential technical support for modern manufacturing.

To ensure your parts achieve the best protective results and visual consistency, it is recommended to discuss material grades and coating thicknesses with processing experts early in the design phase.

Contact our technical team to receive a customized black anodizing assessment report and sample support.