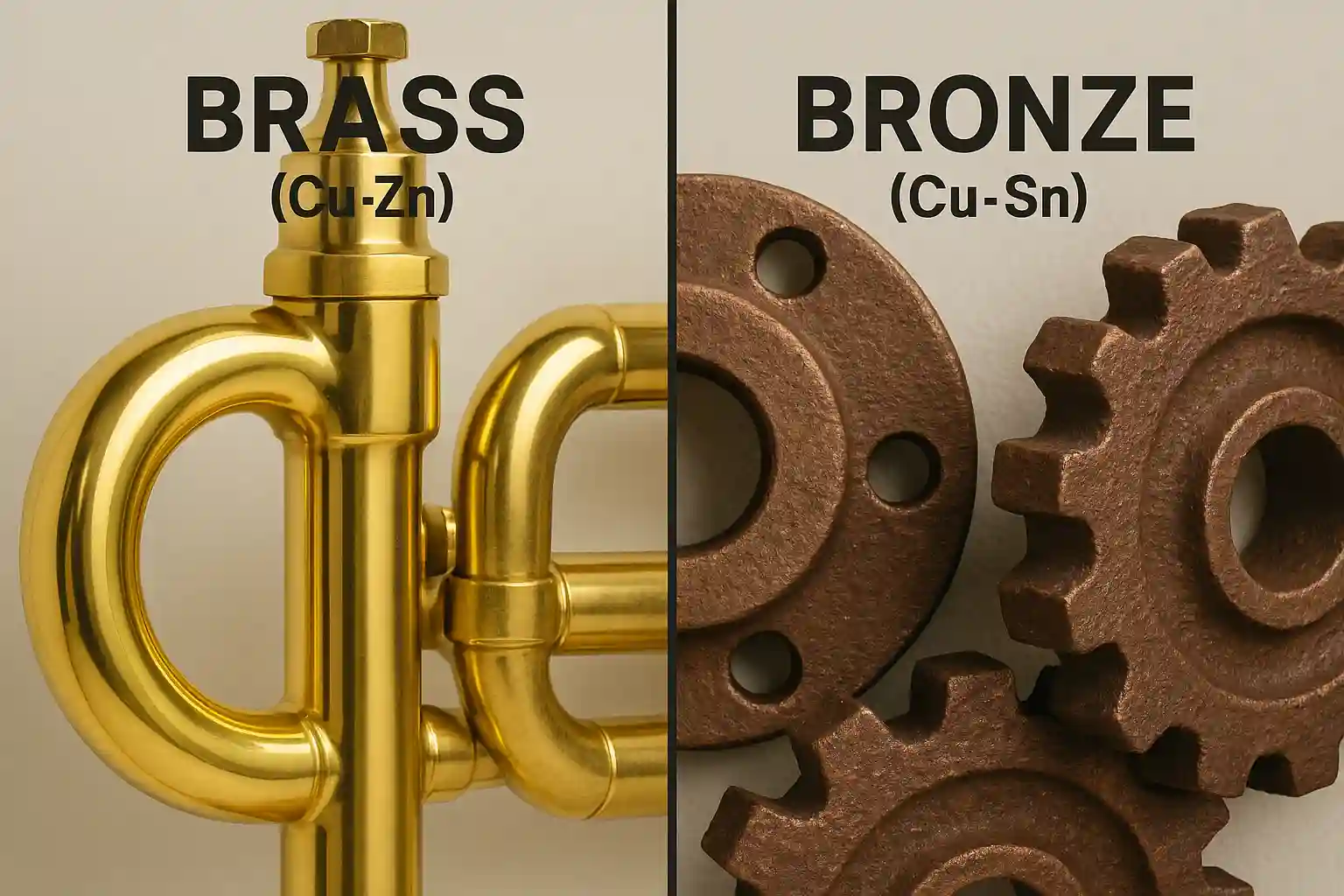

When selecting a copper alloy, manufacturers and designers often face the dilemma of choosing between brass and bronze. Though both materials are visually similar and copper-based, their respective alloying elements—zinc for brass and tin (or others) for bronze—create vastly different mechanical, chemical, and cost properties. Understanding these distinctions is critical for optimizing material performance, ensuring product longevity, and managing production costs. This guide provides a detailed breakdown of both alloys to aid in informed decision-making.

What Is Brass

Brass is a copper alloy primarily composed of Copper (Cu) and Zinc (Zn), with the zinc content typically ranging from 5% to 40%. Its combination of excellent workability, aesthetic golden color, and acoustic properties makes it a widely used material in industrial and decorative sectors.

| Property Overview | Description |

| Primary Element | Zinc (Zn) |

| Appearance | Bright gold or pale yellow hue |

| Key Advantages | Excellent machinability, high ductility, relatively low cost, aesthetic appeal, and natural antimicrobial properties. |

| Key Disadvantages | Lower strength; prone to dezincification corrosion and stress cracking in certain environments. |

| Typical Applications | Musical instruments, decorative items, plumbing fittings, door hardware, ammunition casings, zippers. |

What Is Bronze

Bronze traditionally refers to a copper alloy with Tin (Sn) as the main alloying element. Modern definitions, however, include copper alloys with elements like aluminum, silicon, or manganese. Bronze is highly valued for its strength, wear resistance, and superior corrosion resistance.

| Property Overview | Description |

| Primary Element | Tin (Sn); or Aluminum/Silicon/Manganese |

| Appearance | Reddish-brown or dull gold, prone to developing a dark patina |

| Key Advantages | High strength and hardness, excellent wear and friction resistance, superior corrosion resistance, and good casting qualities. |

| Key Disadvantages | High cost (due to tin); difficult to machine compared to brass. |

| Typical Applications | Marine propellers, heavy-duty bearings, gears, valves, sculptures, commemorative coins. |

Brass vs. Bronze: Key Differences

The table below summarizes the core differences between Brass and Bronze across key metrics:

| Feature | Brass | Bronze |

| Main Alloying Element | Zinc (Zn) | Tin (Sn) or others |

| Hardness / Strength | Moderate, lower | High, stronger |

| Melting Point | Relatively lower (approx. 900°C) | Relatively higher (approx. 950°C to 1080°C) |

| Machinability | Excellent | Good, but higher cutting force and tool wear are expected |

| Seawater Resistance | Fair | Excellent |

| Cost | Lower | Higher |

| Sound Quality | Bright, ringing sound | Deep, dull sound |

Manufacturing Process

The manufacturing processes involve similar steps (melting – casting – fabrication), but the primary difference lies in managing the alloying elements during melting:

| Process Stage | Brass | Bronze |

| Melting Key Point | Zinc Fume Control: Zinc has a low boiling point and tends to vaporize, causing zinc oxide fumes and material loss. Temperature control and flux application are crucial. | Deoxidation: Bronze is sensitive to oxygen. Deoxidizers are typically added during melting to remove dissolved oxygen, improving the density and soundness of the casting. |

| Casting Methods | Common methods include continuous casting, sand casting, and pressure die casting. | Widely uses sand casting, permanent mold casting, and centrifugal casting. |

| Fabrication | Excellent cold and hot working properties; easily drawn, deep-drawn, and rolled into thin sheets or tubes. | Less ductile; often requires hot working. Cold working is more difficult, though some alloys respond well. |

Machinability and Manufacturing

Machinability contrast: Brass creates fine, easy-to-clear chips, resulting in lower manufacturing costs. Bronze forms long, continuous chips, requiring more robust tooling.

- Machinability Performance:

- Brass: Considered one of the most easy-to-machine metal alloys. It requires low cutting forces and produces small, brittle chip fragments that are easily cleared.

- Bronze: Due to its higher hardness, it demands greater cutting power and more robust tooling. Chips are often continuous or stringy, requiring attention to chip management and cooling.

- Tool Wear: Machining hard, high-strength bronze alloys, such as Aluminum Bronze, can significantly increase tool wear, contributing to higher manufacturing costs.

- Weldability: Bronze generally exhibits better weldability than brass. The low boiling point of zinc in brass can lead to excessive zinc fuming and porosity in the weld bead, affecting overall weld quality.

Which Should You Choose

Selecting between brass and bronze requires evaluating the key needs of the application, prioritizing performance, environment, and cost factors:

- For High Strength and Wear: Choose Bronze. Its superior hardness and anti-friction capacity make it essential for critical mechanical components like bearings and gears that handle high loads.

- For Corrosive Environments: Choose Bronze. Its excellent resistance to saltwater and atmospheric corrosion makes it the definitive choice for marine and harsh outdoor fittings.

- For Low Cost and High Volume: Choose Brass. Its lower material cost (zinc vs. tin) and exceptional machinability drastically reduce production time and expense, making it ideal for mass-produced general components.

- For Aesthetics and Formability: Choose Brass. Its gold-like appearance and malleability lend themselves perfectly to intricate shaping and decorative items.

Conclusion

Conclusion: Brass and Bronze, while both copper-based, serve fundamentally different roles in manufacturing. Brass (Cu-Zn) wins on economy and machinability, making it the choice for general and decorative parts. Bronze (Cu-Sn) is defined by its high strength and corrosion resistance, cementing its role as the critical material for heavy machinery and harsh environments.

FAQ

- Which one is more durable?

- Bronze is generally more durable due to its higher strength, hardness, and superior resistance to wear and corrosion in demanding environments.

- Are Brass and Bronze magnetic?

- No. In their standard compositions, neither is magnetic.

- Why is Bronze more expensive than Brass?

- Bronze is more expensive primarily because its main alloying element, Tin (Sn), is significantly more costly than Zinc (Zn), and bronze typically has a higher copper content.

- Which has better electrical conductivity?

- Brass generally has slightly better electrical conductivity than bronze, though both are significantly less conductive than pure copper.

- How can I tell the difference just by sound?

- Bronze’s high damping capacity results in a dull, short, low-frequency sound when struck. Brass’s resonance produces a bright, clear, and ringing sound.

Ready to start your next project with the right alloy? Contact our materials specialists today for personalized consultation on sourcing or custom manufacturing components in Brass or Bronze!