What Is CNC Bronze Machining?

CNC bronze machining is a manufacturing process that uses computer-controlled machines to precisely shape copper-based alloys. Unlike brass, which is primarily a copper-zinc alloy, bronze is an alloy of copper, typically with tin as the main additive. This unique composition gives bronze its excellent corrosion resistance, low friction, and high strength, making it indispensable for demanding applications like marine parts, bearings, valves, and art. While more common materials like steel or aluminum have their place, bronze’s distinct machining characteristics require a specialized approach to ensure optimal results. Our guide will delve into these characteristics, helping you achieve the best quality and efficiency for your projects.

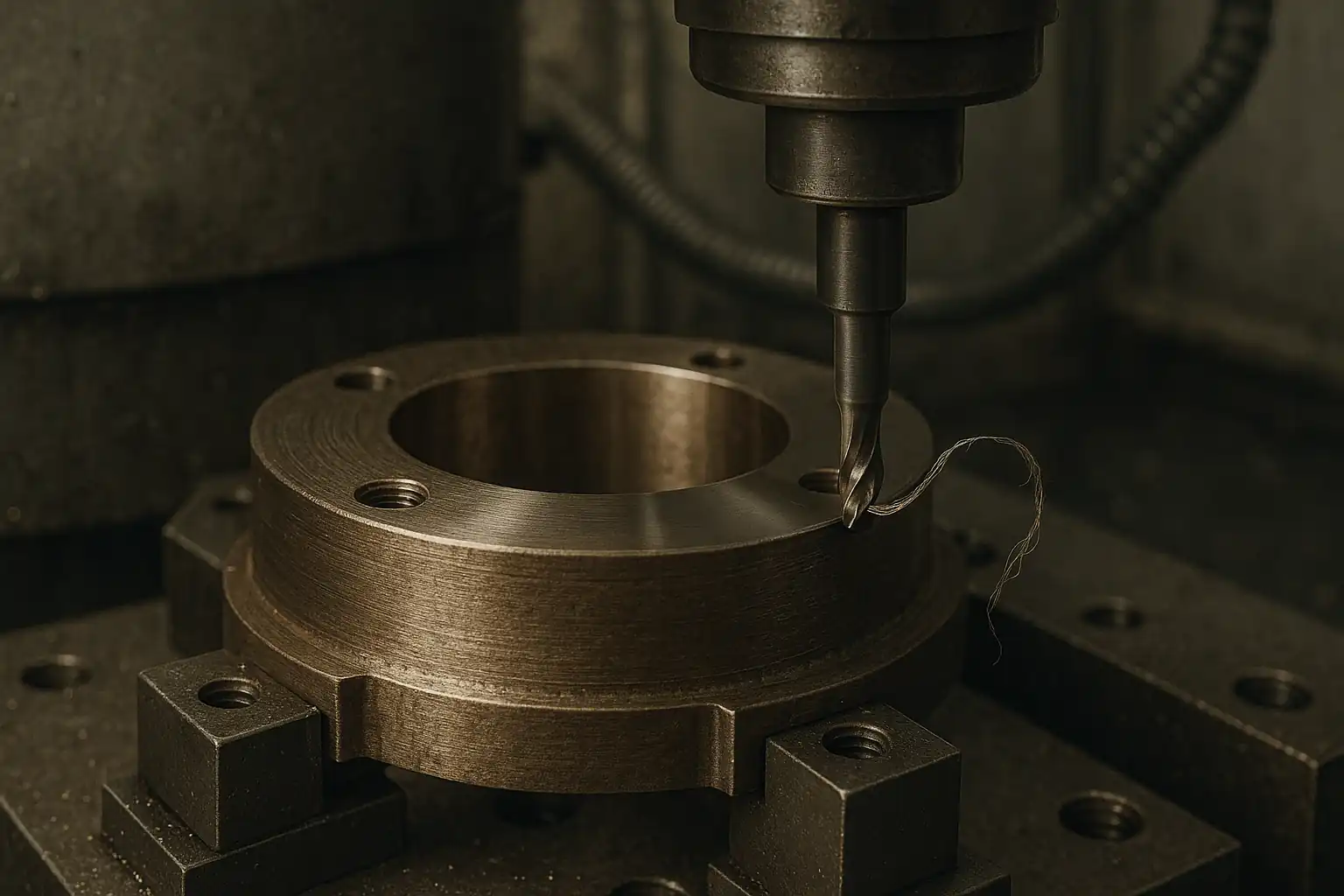

How to Machine Bronze

Successful bronze machining requires more than just knowing how to operate a CNC machine; it demands a precise, systematic approach. Here is a professional, step-by-step guide covering the entire process from preparation to final quality control.

Step 1: Preparation of Equipment and Tools

Before any cuts are made, ensure your setup is optimized for bronze. This includes:

- Machine Selection: Utilize a high-rigidity CNC machine to minimize vibration and chatter. This is the primary factor in achieving high precision.

- Tooling: Choose carbide tools specifically designed for bronze. Focus on a high positive rake angle and a sharp cutting edge to promote clean chip separation and reduce built-up edge.

- Coolant System: Verify that your system can deliver a high-pressure, high-flow stream of coolant directly to the cutting zone for effective heat dissipation and chip evacuation.

Step 2: Setting Parameters and Cutting

Accurate cutting parameters are crucial for both efficiency and quality.

- Cutting Speed: Set the cutting speed based on the specific bronze alloy and part complexity. A higher rotational speed can help create more manageable chips.

- Feed Rate: A lower feed rate will help you achieve a better surface finish and control the length of the chips.

- Depth of Cut: Use a larger depth of cut for roughing to save time, but strictly control it during finishing passes to ensure final accuracy and surface quality.

Step 3: Chip and Coolant Management

Proper chip management is one of the most critical aspects of bronze machining.

- Coolant Application: Direct the high-pressure coolant stream at the cutting point. The force of the fluid will not only dissipate heat and prevent thermal deformation but also effectively flush away the sticky bronze chips, preventing them from wrapping around the tool or scratching the part.

- Chip Evacuation: Ensure a clear path for chips to be removed from the machining area, preventing them from piling up and causing re-cutting.

Step 4: Finishing and Quality Control

The final steps are essential for delivering a high-quality product.

- Finishing: Use a dedicated finishing tool with a minimal depth of cut and feed rate to achieve a high-quality mirror finish.

- Quality Inspection: After machining, perform a thorough inspection using a Coordinate Measuring Machine (CMM) or other precision measuring tools to confirm that all dimensional tolerances and concentricity meet the design specifications.

Bronze vs. Common Metals: A Machinability Comparison

Many engineers and purchasing managers face a decision when choosing between metals. Understanding the key differences between bronze, steel, and brass can help you make a more informed choice.

| Characteristic | Bronze | Steel | Brass |

| Machinability | Good | Fair | Excellent |

| Chip Type | Long and stringy | Short and brittle | Short and brittle |

| Tool Life | Longer | Shorter | Longer |

| Surface Finish | Achievable, but requires care | Good, with optimized parameters | Easily achieves a high finish |

| Cutting Force | Lower | High | Low |

Insights:

- Compared to Steel: Bronze is significantly easier to machine, with lower cutting forces and longer tool life. This leads to higher efficiency, especially for complex parts.

- Compared to Brass: While brass is known for its “free-machining” properties, bronze’s challenge lies in its gummy, stringy chips. Overcoming this requires a different approach to tooling and cooling.

Machinable Bronze: Grades, Advantages, and Applications

In the world of CNC machining, different bronze alloys are chosen for their unique composition and properties, making them suitable for specific applications. Understanding these differences can help you select the right material for your project.

Phosphor Bronze

Phosphor bronze is an alloy of copper with tin and a small amount of phosphorus. The addition of phosphorus acts as a deoxidizing agent during casting, resulting in a cleaner, more durable metal. Its excellent spring qualities and high fatigue resistance make it a go-to choice for parts that undergo repeated stress and flexing.

- Common Grades: C54400, C51000, C52100

- Key Properties: Excellent fatigue strength and wear resistance with good electrical conductivity.

- Typical Applications: Electrical connectors, springs, gears, and high-precision bearings.

Aluminum Bronze

Aluminum bronze is a copper alloy where aluminum is the primary alloying agent, often with additions of iron, nickel, or manganese. This composition gives it a unique combination of high strength and excellent corrosion resistance, especially in marine environments. Its toughness and durability make it ideal for heavy-duty applications.

- Common Grades: C95400, C95500

- Key Properties: Exceptionally high strength, hardness, and corrosion resistance. It is one of the toughest bronze alloys.

- Typical Applications: High-load components like valves, pump bodies, industrial gears, and heavy-duty marine hardware.

Silicon Bronze

Silicon bronze is an alloy of copper and silicon, sometimes with minor additions of manganese or zinc. It is known for its excellent casting properties and a distinctive color that makes it popular for architectural and artistic uses. Its strong corrosion resistance and machinability also make it a reliable choice for industrial components.

- Common Grades: C65500

- Key Properties: Highly corrosion-resistant and easy to weld and machine.

- Typical Applications: Marine parts, chemical processing equipment, fasteners, and architectural fittings.

Tin Bronze

Tin bronze is a copper-tin alloy that has been used for thousands of years. It offers a classic combination of high strength, excellent wear resistance, and good machinability. Modern tin bronze alloys are often used in demanding applications where durability and low friction are critical, such as in bushings and bearings.

- Common Grades: C90300, C90500

- Key Properties: Excellent wear resistance, fatigue strength, and antifriction properties.

- Typical Applications: High-pressure valves, bearings, bushings, and pump components.

I understand. Here is the CTA conclusion paragraph in English:

Frequently Asked Questions (FAQ)

Q: How do you ensure concentricity and tolerance for high-precision parts like bearings?

A: We understand the importance of high precision for components like bearings. We use high-rigidity CNC machines to eliminate chatter and employ a Coordinate Measuring Machine (CMM) for precise post-machining inspection, ensuring every part meets your exact specifications for both concentricity and dimensional tolerance.

Q: What is the easiest bronze alloy to machine?

A: Among all machinable bronze grades, Tin Bronze is generally considered the best for cutting performance. It has excellent machinability, produces manageable chips, and allows for superior surface finishes with standard turning and milling processes.

Q: Compared to other common metals, how difficult is brass to machine?

A: Brass is widely recognized as one of the easiest metals to machine. It produces short, brittle chips, requires no complex cutting parameters or tool designs, and is therefore often used for parts that require high production efficiency.

From Guide to Partnership: Making Your Project a Reality

We know you’re not just looking for a supplier; you’re looking for a partner who understands and can solve your technical challenges. This guide was created to give you a professional insight into bronze machining, from material selection to the finer details of the process—because every step matters. If you have any further needs or are facing technical challenges with a bronze project, please contact us. We will leverage our extensive experience and strict quality standards to provide a customized solution, helping you turn your vision into a finished product.