Electropolishing Process: Definition, Benefits, and Applications

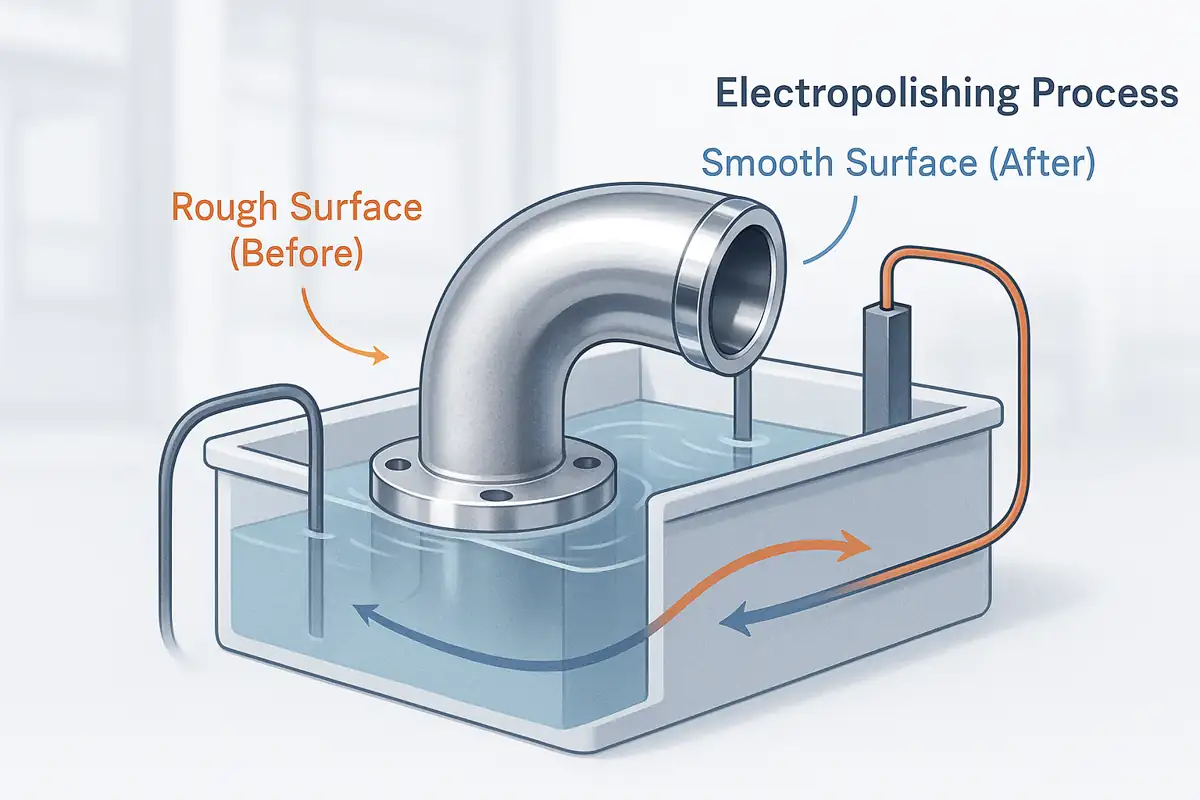

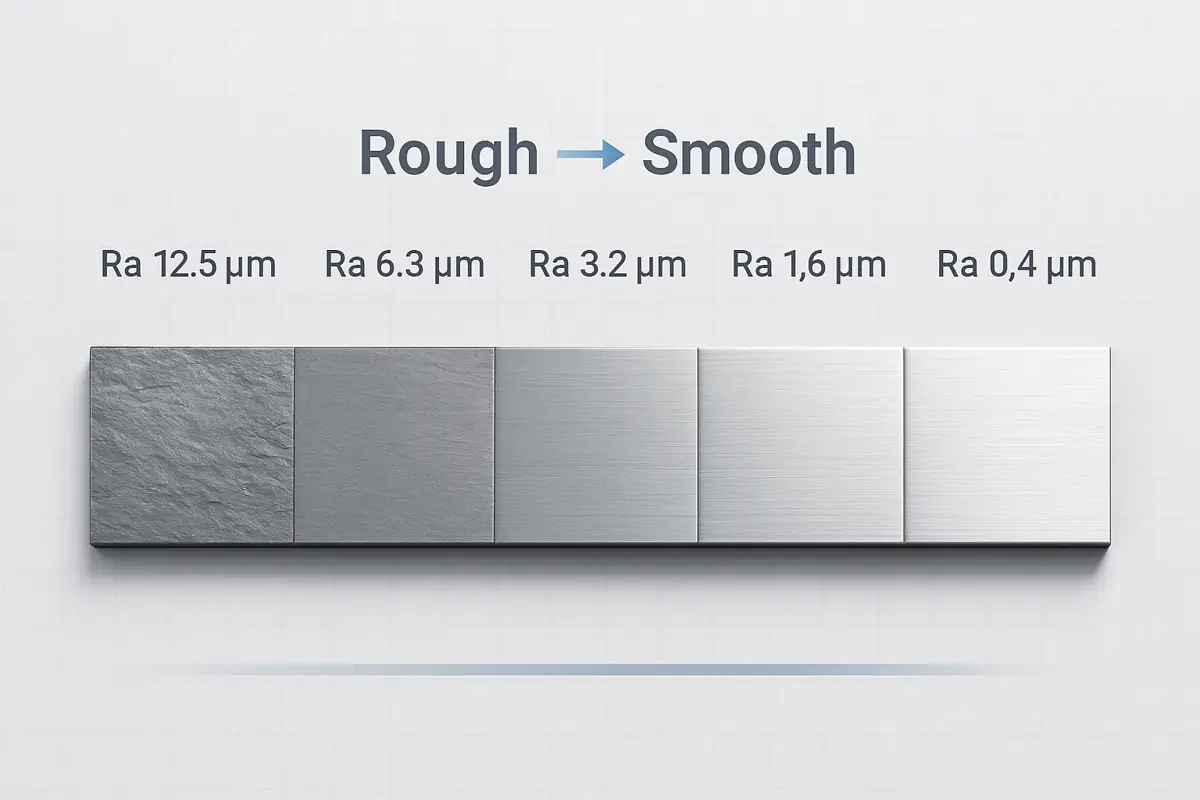

Electropolishing is an electrochemical finishing process that smooths and brightens metal surfaces by removing a thin layer of material. It enhances corrosion resistance, cleanliness, and appearance, especially for stainless steel components.

Read article