Black Anodized Aluminum: A Comprehensive Guide to Benefits, Process, and Limitations

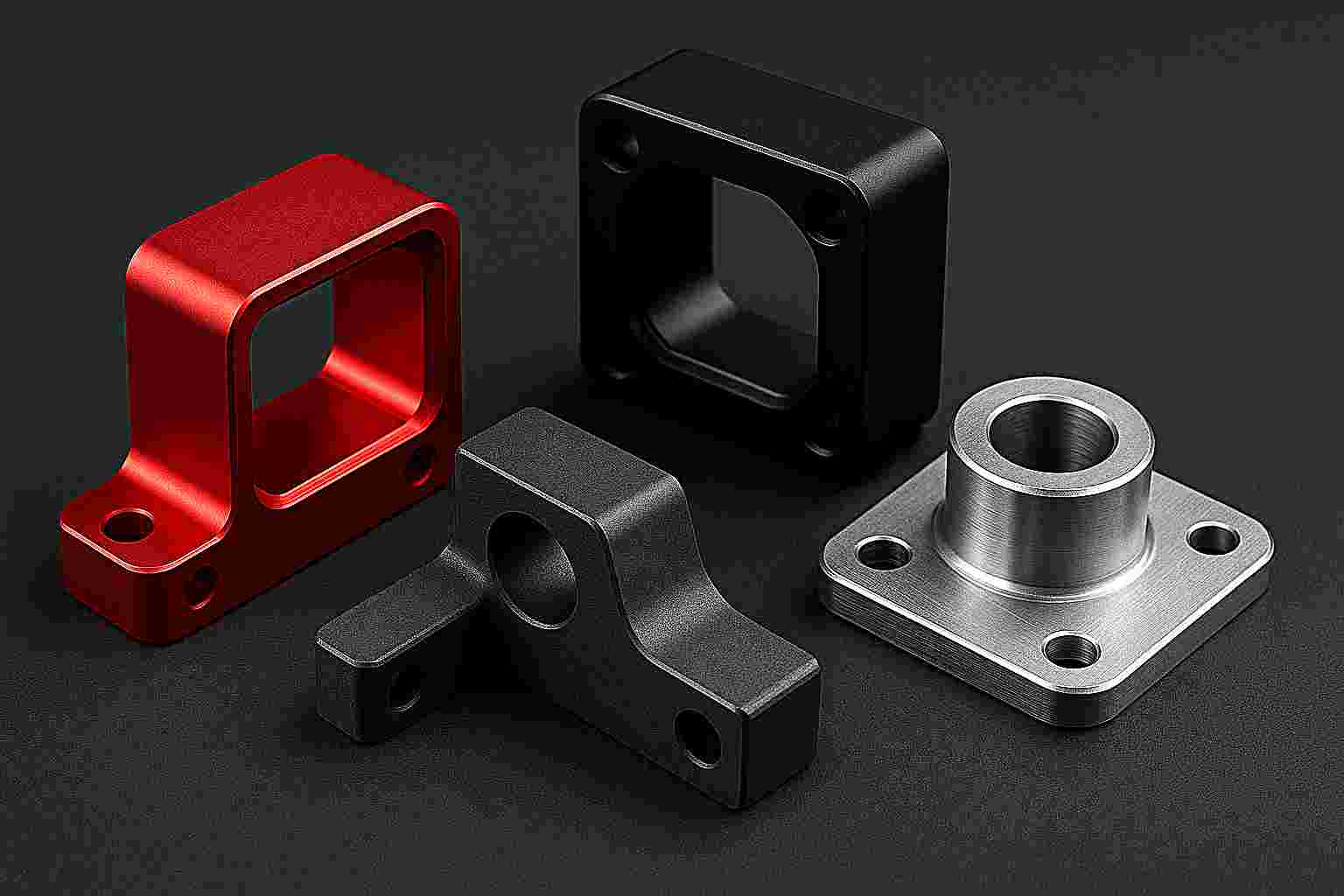

Black anodized aluminum is a widely used surface finish for CNC-machined parts, combining a controlled aluminum oxide layer with black dye and sealing to improve durability and appearance. This article explains how black anodizing works, outlines its main advantages in wear resistance, corrosion protection, thermal emissivity, and light absorption, and clarifies important limitations related to UV exposure, chemical stability, temperature, and electrical insulation. It also discusses suitable aluminum alloys, process materials, and key design considerations such as dimensional growth, tolerance control, and batch color consistency. Typical applications and a comparison with black powder coating are provided to help engineers select an appropriate finishing process for their components.

Read article