In CNC milling, mastering the two fundamental cutting strategies—Climb Milling and Conventional Milling—is crucial for achieving efficiency. The relationship between the cutter’s rotation direction and the workpiece’s feed direction fundamentally dictates the entire machining process result, directly impacting tool life, surface finish, and machine stability.

What is Climb Milling?

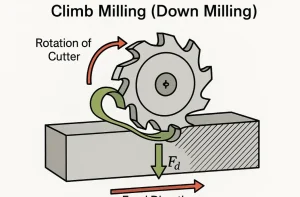

Climb Milling (or Down Milling) is a process where the cutting tool’s rotation direction is the same as the workpiece’s feed direction. In this mode, each cutting edge enters the material at the maximum chip thickness and cleanly exits the workpiece as the cutting thickness decreases to zero.

What is Conventional Milling?

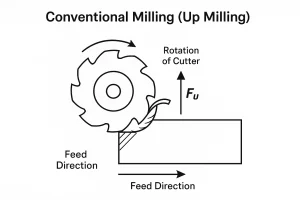

Conventional Milling (or Up Milling) is a process where the cutting tool’s rotation direction is opposite to the workpiece’s feed direction. Each cutting edge enters the material at zero chip thickness, with the cutting thickness gradually increasing to maximum before exiting.

The History of Conventional Milling

To understand today’s preferred strategy, we must start with history. Before the widespread adoption of modern CNC machines, Conventional Milling was the “conventional” approach, not because it was the most effective, but because the inherent defect (Backlash) of the machines made it the only safe option.

Why Was Conventional Milling Necessary?

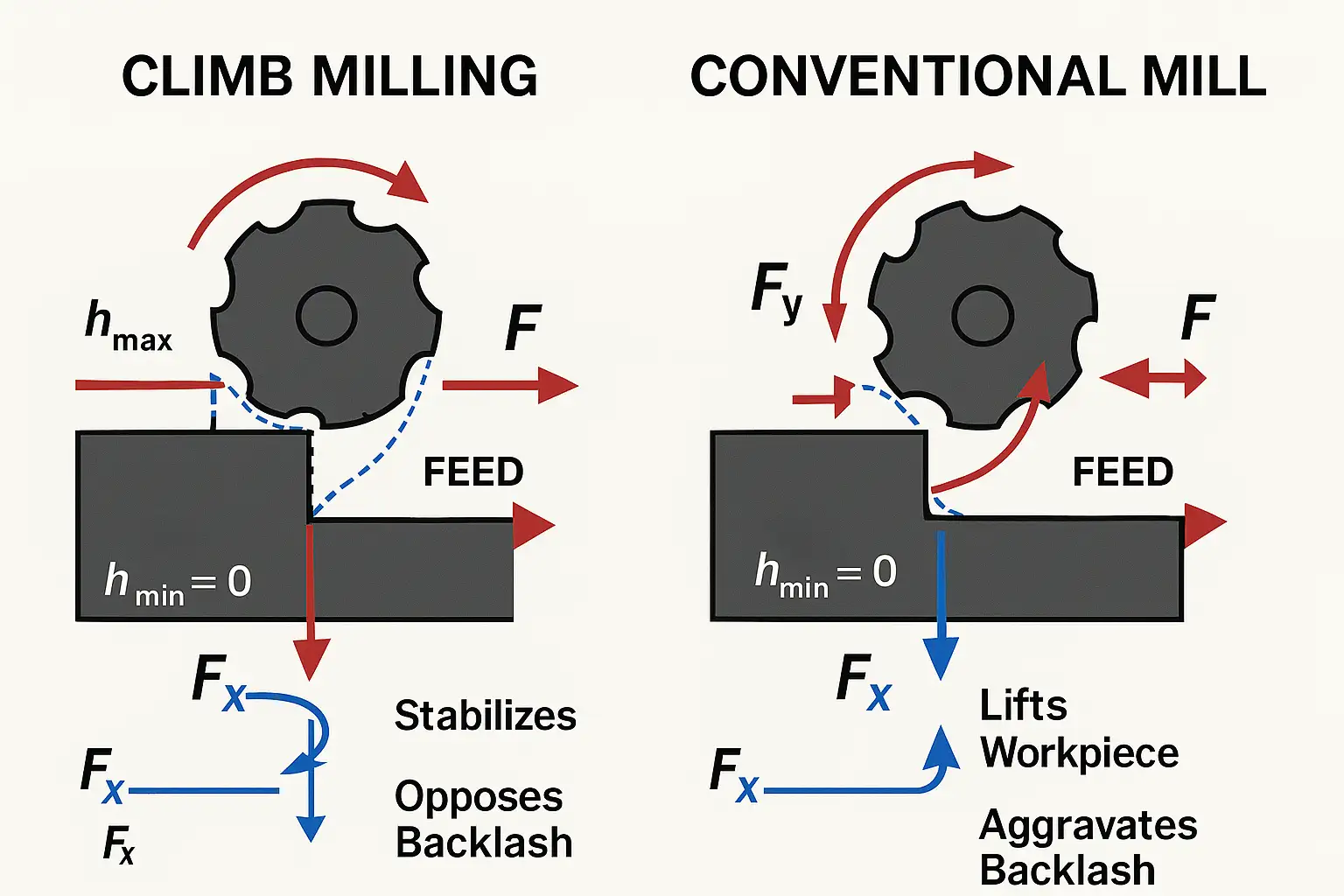

In older milling machines, mechanical backlash (the play between the lead screw and the nut in the table) was an unavoidable defect. The cutting forces in Conventional Milling act upward, resisting this backlash by forcing the lead screw against one side, thus achieving relative stability and avoiding the loss of control that Climb Milling would cause and the danger to the operator.

Disadvantages of Conventional Milling

Once modern machines overcame the backlash issue, the inherent technical flaws of Conventional Milling became apparent:

- Short Tool Life and High Wear: Since the tool starts the cut from zero thickness, the cutting edge experiences rubbing and friction on the material surface, accelerating tool wear and diffusing a significant amount of heat into the workpiece.

- Poor Surface Quality and Work Hardening: The friction and rubbing cause the material to be stretched and marred, leading to work hardening in the cutting zone.

- Poor Chip Evacuation and Unstable Clamping: Chips tend to be dragged back into the cutting area, causing re-cutting, and the cutting forces tend to lift the workpiece, requiring more complex clamping fixtures.

Advantages of Conventional Milling

Despite its disadvantages, Conventional Milling offers a slight advantage when machining castings or forgings with oxidized or hardened surfaces. Its thin-to-thick cutting action helps the tool effectively penetrate this hardened surface layer. Furthermore, the gradually increasing cutting force inherent in Conventional Milling sometimes helps suppress chatter in materials prone to vibration (such as thin-walled parts).

Climb Milling: The Modern CNC Standard

The advantages of the Climb Milling mode have always been highly regarded in the industry, representing the ideal state of milling.

Advantages of Climb Milling

The technical advantages of Climb Milling are overwhelming:

- Excellent Tool Life and Thermal Control: The cutting edge enters at maximum thickness, ensuring highly efficient shearing. The heat generated is carried away with the thickest chips, significantly lowering the tool temperature.

- Superior Surface Finish: The cutting edge cleanly exits the workpiece at zero thickness. This cutting action minimizes friction, resulting in an extremely high surface finish.

- Self-Tightening Stability: The cutting force acts downward onto the table, creating a “self-clamping” effect that enhances workpiece stability, which helps reduce vibration and chatter during machining.

Limitations of Climb Milling

- High Machine Rigidity Requirement and Vibration: Climb Milling enters at maximum chip thickness, creating an initial impact load and high vibration. This necessitates modern CNC machines with high rigidity and reliable backlash compensation to maintain accuracy and stability.

- Sensitivity to Setup and Material Uniformity: Due to the instant, maximum load engagement, if the workpiece is poorly clamped or if the material contains non-uniformities like hard spots or voids, the tool is more prone to sudden deflection or damage than with Conventional Milling.

Backlash Compensation: The Decisive Factor for Climb Milling’s Dominance

Modern CNC machines have completely eliminated the backlash issue of older machines by using high-precision ball screws and advanced electronic backlash compensation systems. Since the technology can now precisely control the axis position and resist initial impact, the full advantages of Climb Milling are unleashed, making it the undisputed standard mode in modern CNC machining.

Core Differences Between Climb and Conventional Milling

To make an informed choice, it is essential to analyze the four core technical characteristics that define these two cutting modes.

1. Direction of Cutting Force and Clamping Stability

The cutting force generated by Climb Milling acts downward on the workpiece, achieving a “self-tightening” effect. Conversely, the cutting force generated by Conventional Milling acts upward on the workpiece, requiring specialized fixturing to counteract the lifting force.

2. Tool Deflection Direction and Accuracy

- Climb Milling: Tool deflection is perpendicular to the workpiece’s feed direction, which directly affects the final dimension and accuracy of the part.

- Conventional Milling: Tool deflection is ** almost parallel** to the workpiece’s feed direction. This results in less error and provides greater control and stability over the process.

3. Tool Wear and Heat Generation

Conventional Milling suffers from rapid tool wear and short life due to initial friction. Climb Milling enters cleanly at maximum thickness, cuts efficiently, and carries heat away with the chips, significantly extending tool life.

4. Material Application Exceptions

Conventional Milling’s thin-to-thick cutting action offers a slight advantage when machining castings or forgings with oxidized or hardened surfaces, helping the tool effectively penetrate the hardened layer.

When to Choose Each Method

The final choice depends not only on the machine type but also closely on the properties of the material being machined (such as aluminum, plastics, foams, or hard alloys).

Practical Guide: Which Method is Better?

| Method | When to Choose (Standard) | Exceptions (When to be Cautious) |

| Climb Milling | The standard for modern CNC machines for almost all operations. Choose when high surface quality and maximized tool life are required, including materials like aluminum. | Use cautiously on older machines without backlash compensation. Be extremely careful with unstable clamping or non-uniform materials. |

| Conventional Milling | Only as an exception. Used for machining hardened layers, or on older machines to counteract backlash. Can be attempted for materials prone to chatter. | Generally avoid when high precision and good surface finish are required. |

Advanced Tip: The Finishing Ghost Pass

- While Climb Milling is usually preferred for finishing passes to achieve optimal surface finish, for parts requiring ultimate precision, a Climb Roughing Pass followed by a light-load Conventional Pass (known as a “Ghost Pass” or “Spring Pass”) can be used. This technique corrects the minor dimensional error caused by Climb Milling’s perpendicular deflection, achieving the most perfect final surface.

Contact Us

If you are looking to optimize your CNC machining processes to extend tool life and improve part quality, our expert team can provide customized machining strategies and fixturing solutions. Contact us today for professional technical consulting.