In the field of CNC precision machining, knurling is a special process that goes beyond simple cutting. It is a critical surface finishing technique used to form complex texture patterns on rotating metal workpieces. These patterns are primarily used to enhance grip, provide anti-slip functions, or create a unique surface texture for functional components. Knurling is commonly found on key mechanical parts such as tool handles, control knobs, and specialized fasteners, playing a vital role in balancing function and aesthetics.

What Is Knurling in CNC Machining

Knurling is a surface forming process. Its core principle is to apply roller pressure to a rotating cylindrical workpiece, forcing the material surface to undergo plastic deformation, thereby forming a uniform, repetitive texture.

Knurling belongs to mechanical deformation processing. Unlike milling or turning, it usually does not remove material. Instead, it forms raised ridges and grooves through the plastic flow of the metal. Knurling is typically performed on CNC lathes, where the automatic synchronization of feed rate and spindle speed ensures high consistency and precision of the pattern across the entire surface.

How the Knurling Process Works

The knurling process relies entirely on synchronized motion and carefully controlled pressure. As the workpiece rotates at a high but stable RPM, the hardened steel knurling roller is fed into the surface. The pressure from the roller must be sufficient to exceed the yield strength of the workpiece material, forcing the metal to flow into the desired texture.

The successful formation of a knurl pattern is critically dependent on the synchronization of the tool feed ratio and the spindle speed. If the tool pitch does not precisely align with the feed per revolution, the roller will mis-track, resulting in a severe, often unrecoverable defect known as “double tracking.” Precision CNC setup is the only reliable way to manage this high-risk synchronization, ensuring the material is redistributed cleanly across the part.

Types of Knurling

Knurling can be classified in several ways depending on how it’s performed, the forming method used, and the geometry of the resulting pattern. Understanding these distinctions helps engineers select the right setup for the intended function, surface quality, and production efficiency.

1. By Operation: Manual vs CNC

Knurling can be performed either manually on a conventional lathe or automatically on a CNC machine. CNC knurling is now the preferred choice for production runs where surface quality, precision, and cycle time are critical, due to the automated spindle synchronization.

2. By Process Method: Form vs Cut Knurling

Once the operation type is defined, the next consideration is how the pattern will be formed—by plastic deformation or by light cutting.

| Method | How It Works | Best For | Advantages | Considerations |

| Form Knurling | Uses high pressure to plastically deform the surface (no chip formation). | Ductile materials like aluminum, brass, and mild steel. | Fast cycle time, strong and deep pattern. | Generates high radial force; not suitable for hard metals or weak setups. |

| Cut Knurling | Removes a thin layer of material with sharp-edged rollers. | Harder alloys such as stainless steel or titanium. | Produces clean edges, lower pressure on the machine. | Requires sharp tooling, stable alignment, and good lubrication. |

Tip: Match the workpiece diameter to the knurl pitch to avoid double tracking, and keep the roller axis perfectly aligned with the spindle.

3. By Pattern Geometry: Straight, Diamond, or Spiral

The roller geometry defines the texture style and the mechanical behavior of the finished surface.

Common knurling patterns: straight, diamond, and spiral.

-

Straight Knurl: Consists of parallel axial lines. Used where components must slide or align linearly.

-

Diamond Knurl: The most common pattern, providing excellent multi-directional grip, ideal for knobs and handles.

-

Spiral (Helical) Knurl: An angled pattern used for decorative or torque-transmitting applications.

Best Materials for CNC Knurling

Selecting the right material is just as critical as choosing the correct knurling tool or process. Different metals respond differently under the high pressure of roller forming.

The performance and consistency of knurling depend heavily on material ductility—the ability of the metal to deform plastically without cracking.

Best Materials

Aluminum, Brass, and Mild Steel are ideal for form knurling. These metals deform smoothly under pressure, producing crisp and uniform textures.

Moderately Difficult Materials

Stainless Steel and Titanium require Cut Knurling and careful control of RPM and feed rate. Adequate lubrication and rigid tool setup are essential to avoid tool chatter or premature wear.

Unsuitable Materials

Cast Iron and other brittle alloys must be avoided. Their low ductility makes them highly prone to surface cracking under knurling pressure, leading to part failure.

Advantages and Limitations of Knurling

Advantages

-

Enhanced Grip: The most practical reason for knurling is to provide secure, slip-resistant handling, especially for manual or adjustment parts.

-

Rapid Process: Compared to milling textured patterns, knurling is faster and requires minimal tool wear.

-

Aesthetic Value: Adds an industrial, high-precision appearance that doubles as branding in many mechanical designs.

-

No Material Waste: Since form knurling displaces rather than removes material, it minimizes chip generation.

Limitations

-

Dimensional Growth: The outward flow of material increases the part’s diameter (typically +0.2 – 0.4 mm), which must be compensated in design.

-

Not Suitable for Brittle Metals: Cast iron and similar alloys may crack under high pressure.

-

Requires Perfect Setup: Even a slight feed/pitch mismatch causes double tracking, which ruins the part.

-

Limited to Cylindrical Geometry: Knurling works best on round parts; non-circular surfaces usually require milling or texturing instead.

When to Use Knurling

Knurling should be applied only when the design demands enhanced surface interaction, tactile control, or torque transfer. It is not an aesthetic afterthought, but a deliberate functional specification. Engineers typically specify knurling in the following scenarios:

-

For Tactile Control: When a part must be operated by hand (e.g., medical device knobs, thumb screws). The knurl ensures a firm, slip-resistant grip, which is non-negotiable in oily or high-temperature environments.

-

For Torque Transmission: When torque needs to be transferred between two parts without relying on complex fasteners. A properly designed knurled interface creates a robust mechanical interlock.

-

For Assembly Friction: To significantly increase friction in press-fit and interference assemblies, preventing rotation or slippage between mating materials (e.g., metal press-fit into plastic).

-

For Aesthetic Signature: For visible components where the texture communicates precision, quality, and craftsmanship, such as high-end electronic dials.

Applications of Knurling in CNC Machining

Knurling plays a vital role in enhancing both functionality and visual design across multiple manufacturing sectors.

Industrial examples of knurled handles, knobs, and adjustment parts.

Its applications can generally be categorized into three groups:

-

Functional Enhancement: Creates anti-slip surfaces on tool handles, adjustment knobs, and medical or laboratory devices.

-

Aesthetic and Branding Purposes: Used on visible components like control dials, giving a premium tactile feel.

-

Assembly and Mechanical Support: Applied to press-fit components to increase friction and provide mechanical interlock.

Common Defects and How to Avoid Them

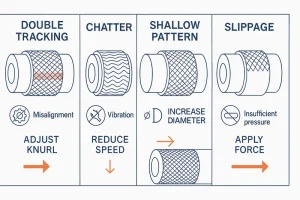

Common knurling defects and how to fix them.

An experienced machinist knows that knurling is an unforgiving process where small setup errors lead to immediate visual defects. Addressing these requires mechanical insight:

| Defect | Primary Cause | Engineer’s Solution or Remedy |

| Double Tracking | The most critical error: Workpiece diameter does not match roller pitch ratio. | Calculate and Fine-tune Diameter: The nominal diameter must be adjusted to an exact multiple of the roller pitch for clean engagement. |

| Chatter / Slippage | Lack of rigidity (tool or workpiece) or insufficient initial pressure. | Maximize Support: Ensure the tool holder is rigid; increase pressure to prevent initial slippage and guarantee consistent track. |

| Shallow Pattern | Insufficient material ductility or pressure was too low to exceed yield strength. | Re-evaluate Method: If increasing pressure fails, switch to the Cut Knurling method to achieve the required depth on harder metals. |

Design and Dimensional Considerations

Plastic deformation during knurling inevitably affects the final part dimensions, a critical factor that must be accounted for in the design phase.

Diameter Change

Knurling typically causes the outside diameter of the part to increase by approximately 0.2mm to 0.4mm. This increase is due to the displaced material being forced outward.

Tolerance Pre-planning

Design engineers must pre-calculate and accordingly reduce the initial diameter of the workpiece to compensate for the dimensional growth caused by knurling, ensuring the final dimension falls within specified tolerances.

Chamfer Preparation

It is highly recommended to chamfer the edges where the knurl begins and ends. This prevents burrs and ensures a clean, well-defined start and end point for the pattern, avoiding edge misalignment.

Drawing Notation

The knurled area, pattern type, and pitch must be clearly indicated on the technical drawing to guide the CNC programmer for precise operation.

Common Questions About CNC Knurling

Q1. Can CNC lathes perform knurling automatically?

A: Yes. Modern CNC lathes can achieve highly automated and consistent knurling by precisely synchronizing spindle speed and feed rate, which is difficult to achieve on manual lathes.

Q2. What is the difference between form and cut knurling?

A: Form knurling (Form) uses high pressure for plastic forming and produces no chips, suitable for ductile materials. Cut knurling (Cut) removes a small amount of material through light cutting, requires less force, and is better suited for harder metals like stainless steel.

Q3. Does knurling affect dimensional accuracy?

A: Yes. Knurling inevitably increases the external diameter of the part. If tolerance is not pre-planned in the initial machining, the finished part will be out of dimensional accuracy.

Q4. Can hardened steel be knurled?

A: No. Once steel is hardened, it loses the ductility required for plastic deformation. Attempting to knurl hardened steel will damage the tool or cause the workpiece surface to crack. Knurling must be done before the material is heat-treated or hardened.

Q5. How to achieve uniform knurling on stainless steel?

A: The key is to use a Cut Knurling tool, ensure the workpiece is rigidly supported, and use high-quality cutting oil. Additionally, slightly increasing the feed rate helps the tool “track” the pattern stably on the harder surface.

Conclusion

Knurling is an indispensable technology in modern precision manufacturing, offering value beyond just surface texture by balancing functional performance and aesthetic requirements. By carefully selecting the correct pattern type, tool setup, and adjusting parameters according to the material, manufacturers can achieve superior grip, durability, and visual balance in their part designs.

Work With Minghe CNC for Precision Knurling Solutions

At Minghe CNC, we specialize in precision turning and advanced surface finishing — including detailed knurling services for both industrial and decorative applications.

If your next project requires accurate texture control and consistent quality, contact our engineering team to discuss your specifications or request a free quote today.