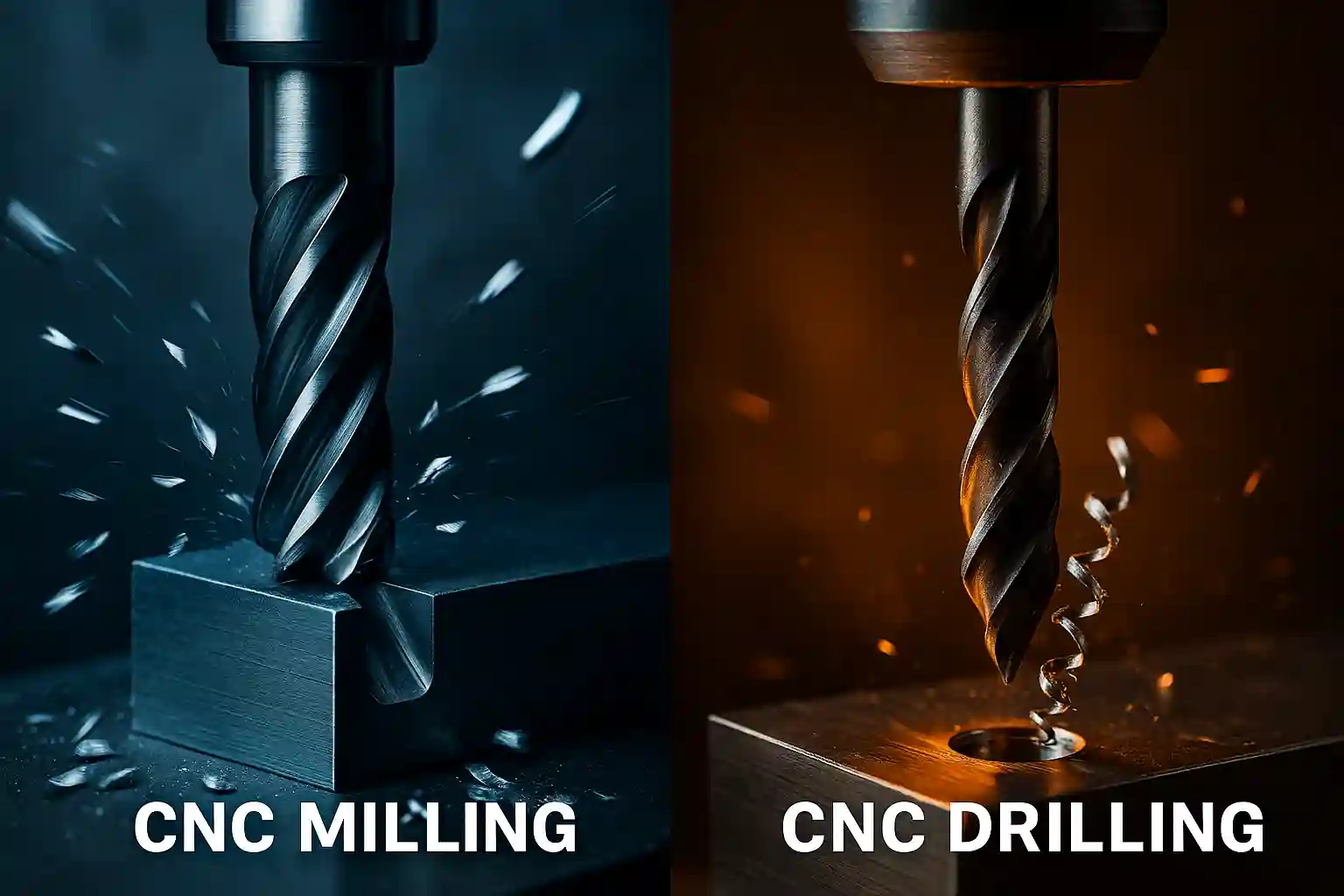

Boring Machining Comprehensive OverviewIn modern manufacturing, CNC milling and CNC drilling are two fundamental and crucial machining processes. Although both are used to remove material, they have distinct differences in their working principles, applications, and end results. A deep understanding of these distinctions is key to optimizing production efficiency and ensuring part quality.

What is CNC Milling?

CNC milling is a process that uses a multi-point rotating tool (a milling cutter) to remove material from a workpiece as the tool moves along the X, Y, and Z axes of a machine. It’s like a “sculptor” that can move freely in 3D space to create complex geometries.

What is CNC Drilling?

CNC drilling is a process that uses a two-point rotating tool (a drill bit) to cut into a workpiece along its axial direction to create a cylindrical hole. It is a specialized process focused on making holes quickly and accurately.

Comprehensive Comparison

| Feature | CNC Milling | CNC Drilling |

| Working Principle | The tool moves in 3D space, cutting both laterally and axially using its side and end cutting edges. | The tool moves along a single axis, cutting and extruding material with its tip. |

| Primary Function | Shaping and sculpting to create planes, profiles, slots, and complex 3D shapes. | Creating holes, used for cylindrical holes of various sizes and depths. |

| Tool Type | Multi-point milling cutters with diverse shapes, such as end mills and ball nose mills. | Two-point drill bits with a relatively standard design, such as twist drills and center drills. |

| Movement | The tool moves simultaneously on the X, Y, and Z axes, following a complex tool path. | The tool feeds linearly along a single axis (the Z-axis). |

| Cutting Force | Lateral (transverse) force is the primary component, which can cause tool deflection. | Axial (longitudinal) force is the primary component, which makes the tool more stable. |

| Surface Finish | Can achieve a very high surface finish, suitable for precision parts. | The inner wall of the hole typically has a rougher finish due to the cutting and extrusion, often requiring a reaming or boring operation to improve. |

| Suitable Materials | Highly versatile, capable of machining everything from soft plastics to hard steel and titanium alloys. | Also versatile, mainly used for relatively uniform materials like metals and plastics. |

| Tool Cost | Tools are complex and diverse, often with a higher cost. | Tools are simple and standardized, with a lower cost. |

Working Principle

CNC milling uses multi-axis motion to cut materials both laterally and axially with the side and end cutting edges. Its principle is similar to sculpting and shaping. In contrast, CNC drilling relies on single-axis motion, and its cutting action is more like a rapid penetration, primarily removing material through the cutting and extrusion of its tip.

Primary Function

CNC milling is the most versatile machining process, capable of performing plane milling, slotting, contouring, pocketing, and 3D surface shaping. It is the top choice for complex “sculpting.” CNC drilling, on the other hand, is single-function, limited to creating cylindrical holes of various sizes and depths.

Tool Type

Milling tools come in a wide variety of shapes and sizes, from two to multiple flutes, such as flat end mills, ball nose mills, and face mills, each designed for specific tasks. Drill bits are relatively simple and standardized, primarily twist drills highly optimized for efficient hole-making.

Movement

A milling tool typically requires simultaneous movement on the X, Y, and Z axes to follow a complex tool path. Drilling movement is extremely simple, as the tool only needs to feed linearly along its axis (the Z-axis) to complete the hole before retracting, with no lateral movement.

Cutting Force

During milling, especially side milling, the tool is subjected to significant lateral (transverse) cutting forces. This can cause tool deflection and machine vibration, requiring high rigidity. During drilling, the cutting force is predominantly axial (longitudinal), which makes the tool more stable and better for deep hole drilling.

Surface Finish

Milling can achieve a very high surface finish with finishing passes, especially when using a ball nose cutter for 3D surfaces, making it suitable for high-precision requirements. The inner wall of a drilled hole typically has a lower surface finish due to the extrusion and tearing nature of the cut, often requiring a subsequent reaming or boring operation to improve it.

Suitable Materials

Milling is extremely adaptable and can machine almost any material, from soft plastics and wood to hard steels, titanium, and nickel alloys. Drilling is also versatile but is primarily used for relatively uniform materials like metals and plastics. Special drills and strategies are needed for very hard or brittle materials to prevent chipping.

Tool Cost

Milling cutters are complex and diverse, often featuring multiple flutes or indexable inserts, which typically results in a higher cost. Drill bits have a simple design and are mass-produced, so their cost is lower, making them ideal for high-volume, single-size hole-making.

Advantages and Limitations

CNC Milling

- Advantages:

- Extreme Versatility: A milling cutter can perform side milling, slotting, pocketing, and 3D contouring, making it an incredibly versatile tool.

- Excellent Surface Quality: With finishing passes, milling can produce parts with a very high-quality surface finish.

- Complex Geometries: Milling is the go-to process for creating molds, complex parts, and intricate features.

- Limitations:

- Low Efficiency for Holes: While a milling cutter can make a hole, it is less efficient and precise for a standard cylindrical hole than a dedicated drill bit.

- Requires High Rigidity: High lateral cutting forces can cause tool deflection or chatter, which demands a rigid machine and tool.

- High Tool Cost: The variety and complex design of milling cutters typically results in a higher cost.

CNC Drilling

- Advantages:

- Highly Efficient: The drilling process is optimized for making holes quickly and efficiently.

- High Axial Rigidity: A drill bit is designed to handle high axial forces, allowing for fast and deep cutting.

- Lower Tool Cost: Compared to multi-functional milling cutters, drill bits are typically more affordable, making them ideal for high-volume hole-making.

- Limitations:

- Single Function: Drilling is limited to creating round holes; it cannot mill planes or complex profiles.

- Rougher Finish: The inner surface of a drilled hole is often rough due to the cutting and extrusion process, which may require a secondary finishing operation.

- Prone to Burrs: Burrs can form at the exit of the hole, requiring an extra deburring step.

Typical Applications

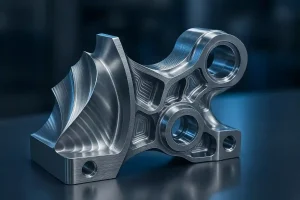

CNC Milling

- Mold Making: Used to create complex molds for injection molding and die-casting.

- Aerospace: For machining intricate parts like wings and engine components.

- Prototyping: Ideal for quickly producing product prototypes and functional parts.

- Medical Devices: For manufacturing implants and precision surgical tools.

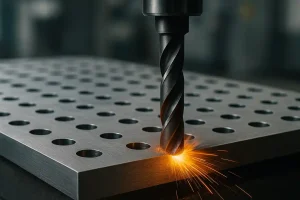

CNC Drilling

- Threaded Holes: To prepare a hole for subsequent tapping.

- Assembly Holes: To provide precise locations for bolts, pins, or rivets.

- Fluid Channels: For creating pathways for liquids or gases within a component.

- Circuit Boards: For drilling holes for electronic component leads or vias.

Conclusion

In short, CNC milling is the “master sculptor,” responsible for carving a workpiece into various complex forms, while CNC drilling is the “hole specialist,” focused on creating precise holes quickly and efficiently. While a milling cutter can sometimes be used to create a hole, a drill bit will almost always be more efficient and precise for standard cylindrical holes. In manufacturing, these two processes are often used together to complete a single part.

CNC Milling & Drilling Services

Understanding the differences between CNC milling and drilling is the first step toward improving product quality and production efficiency. As a professional CNC machining service provider, we not only master both core processes but also tailor the best machining solutions to your specific needs. Whether you need to manufacture high-precision, complex parts or require high-volume, efficient drilling, we offer a one-stop solution.

Contact our team of experts today and let us help you turn your design ideas into reality.