Copper machining is a highly specialized area of subtractive manufacturing that is essential for producing high-performance components across numerous critical industries. While copper’s excellent electrical and thermal conductivity make it invaluable, its inherent softness, ductility, and high thermal expansion coefficient present significant challenges in the machining process. Success in copper machining relies on a delicate balance of optimized machine settings, specialized tooling, and deep material knowledge to achieve tight tolerances—often down to 0.01 mm or less and superior surface finishes. This framework outlines the complete process, from material selection and process mechanics to overcoming common difficulties, ensuring the final parts meet the stringent quality and performance demands of modern technology.

What Is Copper Machining

What Is Copper Machining is a definition that goes beyond simple material removal; it is the precision shaping of copper and copper alloys (e.g., brass, bronze, Beryllium Copper) using CNC machinery like mills, lathes, and drilling centers. This subtractive process is necessary because copper’s unique properties—namely, its exceptional thermal conductivity (up to 400 W/m·K) and electrical conductivity—make it indispensable for applications requiring rapid heat dissipation or efficient current transfer. The core principle for machining copper, unlike steel or aluminum, is managing its extreme ductility. This characteristic means the material tends to deform, tear, or smear rather than forming predictable, easily broken chips, necessitating entirely different process strategies to maintain dimensional integrity and surface quality.

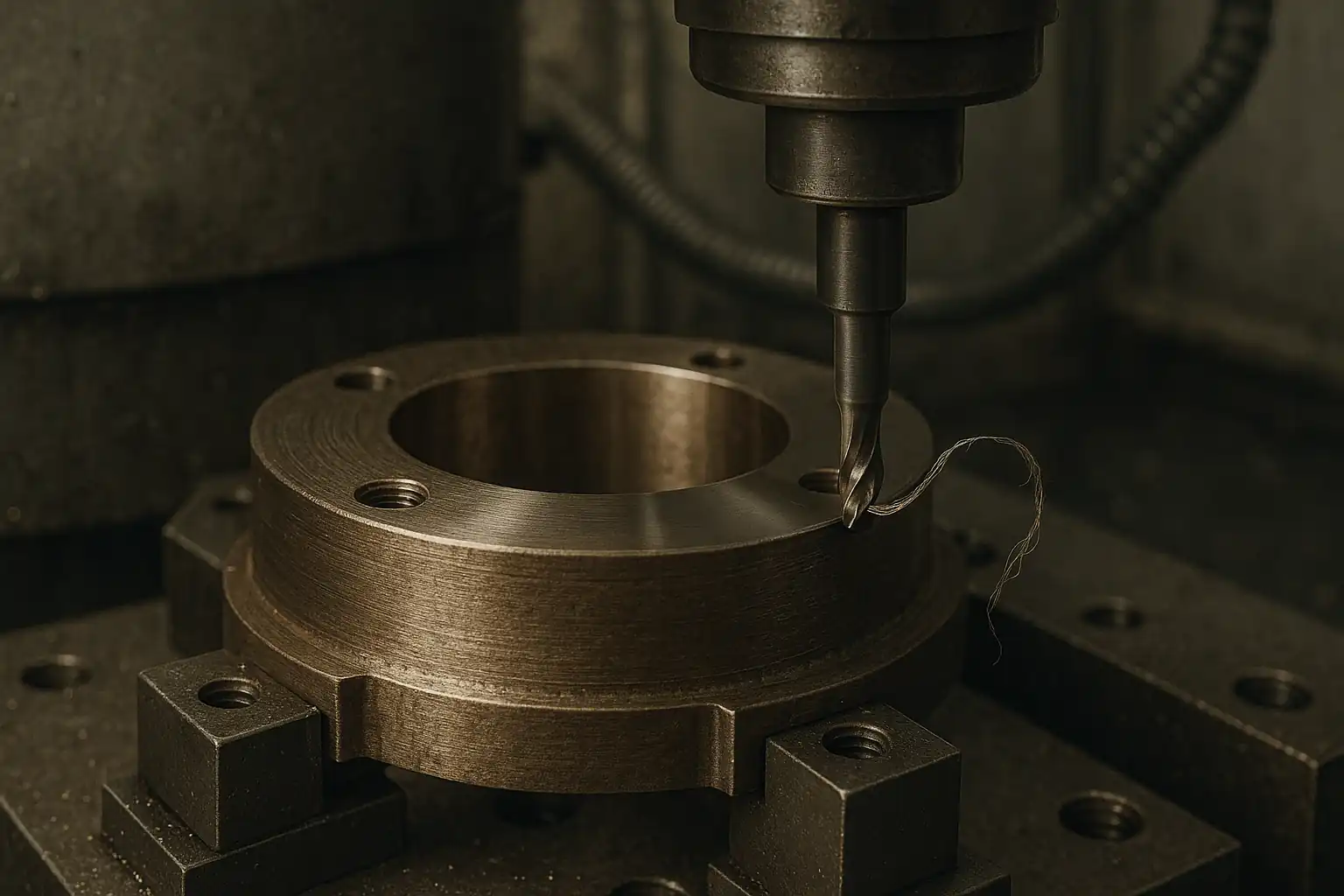

How the Copper Machining Process Works

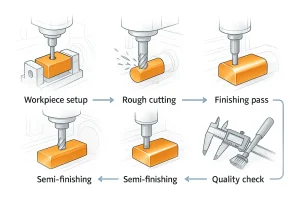

The effective production of high-precision copper components follows a rigorous process designed to mitigate the material’s inherent difficulties. How to machine copper effectively involves several critical phases. The sequence below summarizes a typical CNC copper machining workflow used in precision production environments.

Step-by-step process of machining copper parts from setup to final inspection.

- Workpiece Clamping: Copper’s softness demands careful fixturing to prevent deformation. Low-force, high-contact area clamping or custom soft jaws are frequently employed to maintain geometric accuracy.

- Roughing: Initial material removal is performed with deep cuts and high feed rates. This is counter-intuitive but necessary; high-speed, aggressive cutting helps break the copper chips and ensures the tool spends minimal time rubbing against the material, which would generate excessive heat.

- Coolant management: Continuous, high-volume flood coolant (oil-based or high-quality emulsion) is non-negotiable. It serves three roles: cooling the work zone to combat high thermal expansion, lubricating the cut to prevent sticking, and aggressively flushing the stringy chips away from the cutting zone.

- Finishing: The final pass focuses purely on surface finish and dimensional accuracy. Light depths of cut, ultra-sharp tools, and precise machine control are utilized to achieve tolerances as tight as ± 0.005 mm and surface finishes down to Ra 0.4 µm.

- Chip Control: Specialized tool geometries (chip breakers) and pecking cycles in drilling are employed to prevent the formation of long, continuous copper strands that can tangle, damage the part, or injure the operator.

Materials and Grades in Copper Machining

Choosing the right copper material involves balancing electrical conductivity, strength, and machinability. In CNC machining, copper materials are generally classified into several main material types, followed by the most commonly used machinable grades.

I. Main Material Types

| Material Type | Key Characteristic | Machinability Overview | Typical Uses |

| Pure Copper (C11000 family) | Highest electrical and thermal conductivity, but extremely soft. | Poor. Prone to smearing and Built-Up Edge (BUE) formation. | Electrical conductors, busbars, heat exchangers. |

| Free-Machining Alloys (e.g., C14500, C14700) | Slightly lower conductivity but excellent chip-breaking and tool life. | High. Excellent chip control and process speed. | High-speed turned parts, precision connectors. |

| Brass (Cu–Zn Alloy) | Excellent machinability and corrosion resistance. | High. Ideal for general machining. | Valves, plumbing fittings, fasteners. |

| Bronze (Cu–Sn Alloy) | High strength and wear resistance. | Moderate. Suitable for friction-heavy parts. | Bushings, sleeves, bearing housings. |

| Beryllium Copper (Cu–Be Alloy) | Combines high conductivity with spring-like strength after heat treatment. | Moderate/Specialized. Requires specific safety protocols. | Aerospace connectors, high-stress springs. |

| Cupro-Nickel (Cu–Ni Alloy) | Superior corrosion resistance in marine environments. | Moderate. | Marine heat exchangers, seawater piping. |

II. Common Machinable Copper Grades

| Grade | Name / Composition | Key Features | Machinability | Typical Applications |

| C11000 | Electrolytic Tough Pitch Copper ($99.9\%$ Cu) | Highest conductivity, very soft, prone to adhesion. | Poor | Busbars, electrical contacts. |

| C14500 | Tellurium Copper ($\approx 0.5\%$ Te) | Best balance of conductivity and cutting efficiency. | Excellent | Connectors, welding tips, screw-machine parts. |

| C14700 | Sulfur Copper ($\approx 0.3\%$ S) | Good chip control and moderate conductivity. | Good | Fittings, plumbing components. |

| C10100 | Oxygen-Free Copper | Ultra-high purity, vacuum and cryogenic compatibility. | Poor | Vacuum seals, superconductors. |

| C17200 | Beryllium Copper | High strength (up to $1300 \text{ MPa}$ after heat treatment). | Moderate | Aerospace molds, spring contacts. |

Key Machining Parameters and Tooling Tips

The technical heart of successful Copper Machining lies in optimizing Copper Machining Parameters—cutting speed (Vc), feed per tooth (fz), and axial depth of cut (ap)—in concert with specialized tooling.

- Rake Angles: Cutting tools must have a high positive rake angle (15° to 25°) and a large clearance angle. This provides a sharp edge that slices the material cleanly rather than pushing it, significantly reducing cutting forces and heat.

- Cutting Speed: Generally, high cutting speeds (up to 300 m/min for finishing) are beneficial. The goal is to keep the tool cutting efficiently, preventing the copper from welding onto the edge.

- Feed Rate: A high feed rate (high chip load) is often preferred to encourage the chip to break off cleanly. Light feeds increase rubbing and BUE risk.

- Tool Material: Uncoated, highly polished carbide tools are often the first choice. For demanding applications, tools coated with low-friction coatings (like Diamond-Like Carbon, DLC) are used to minimize adhesion and achieve a superior copper machining surface finish.

- Edge Preparation: The cutting edge must be razor-sharp. A slight honing is acceptable for roughing to improve edge strength, but a perfectly sharp, polished edge is mandatory for high-quality finishing passes.

Common Challenges and Solutions in Copper Machining

Copper’s inherent material properties create several recurring operational hurdles that require specific mitigation strategies.

| Challenge | Cause | Solution |

| Built-Up Edge (BUE) | Copper adheres (welds) to the tool tip due to friction and heat. | High positive rake tools, polished tool surfaces, and abundant, high-lubricity coolant. |

| Long, Stringy Chips | Extreme ductility of pure copper grades. | Use free-machining grades (C145), implement chip-breaker geometries on inserts, and use specialized pecking cycles (e.g., G83 for drilling). |

| Thermal Expansion | High coefficient of thermal expansion causes dimensional instability during cutting. | Use high-flow, temperature-controlled coolant. Let the part stabilize to ambient temperature before critical measurement/finishing. |

| Poor Surface Finish | Material smearing, tearing, or vibration due to low rigidity. | Ensure machine rigidity, use very sharp and polished tools, and maintain constant high chip load during the finishing pass. |

How to prevent built-up edge in copper machining is the most crucial problem to solve. The combination of high cutting speed, sufficient positive rake, and aggressive lubrication is the only reliable method for preventing copper particles from accumulating and compromising the component’s final quality.

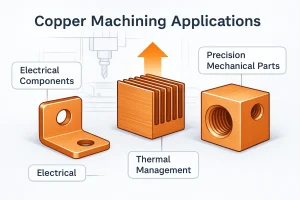

Applications of Machined Copper Parts in Industry

The unique combination of thermal and electrical performance capabilities makes machined copper parts essential components in numerous high-reliability sectors.

Typical applications of precision copper machining: electrical components, thermal management, and precision mechanical parts.

- Electronics & Semiconductors: High-purity copper is machined into large heat sinks and cold plates for supercomputers, power modules, and specialized scientific equipment to manage immense thermal loads.

- Electrical Power Distribution: C110 and C145 copper are the standard for busbars, high-current connectors, and switchgear contacts where minimal resistance is critical for safety and efficiency.

- Aerospace & Defense: Copper alloys are used in demanding environments, such as combustion chamber liners and nozzles in rocket engines, utilizing copper’s ability to rapidly transfer and dissipate heat away from critical areas.

- Automotive (EV/Hybrid): Machined copper is used extensively in battery cooling systems and high-voltage power electronics due to its lightweight heat management properties and superior conductivity compared to aluminum.

- Medical: Used in X-ray targets and specialized RF shielding due to its density and high electrical characteristics.

Conclusion

Copper machining is a critical discipline for manufacturing high-performance thermal and electrical components. While the material presents challenges related to BUE, stringy chips, and thermal expansion, these are expertly overcome through a tailored approach involving high-positive rake geometry, free-machining alloys like C145, precise spindle parameters, and robust coolant management. Our engineering team leverages this technical expertise to deliver copper components that adhere to the tightest tolerances required by the electronics, aerospace, and energy sectors. Request a quote from our engineering team or upload your drawings for a fast engineering review and quote.