When specifying brass for CNC machining projects, engineers frequently compare H59 and H62—two widely used Chinese grades defined in GB/T 5231 for wrought brasses. The choice impacts machinability, corrosion behavior (including dezincification), achievable surface finish, and total cost. Because “international equivalents” vary by standard and especially by lead content and alloying additions, always specify by exact chemical composition and required compliance in your purchase documents.

This guide provides an engineering-focused comparison covering composition, properties, chip formation, dezincification considerations, and application-based selection.

What Is H59 Brass?

H59 brass, often chosen for its cost efficiency, is a highly favored material for high-volume machined components. Its specific properties are highly beneficial for automated machining processes.

Chemical Composition

| Spec Item | H59 (Approx.) |

| Cu (wt.%) | 57–60 |

| Zn (wt.%) | Balance |

| Pb (wt.%) | trace / per order |

| Phase | alpha + beta |

The composition of H59 places it close to the boundary of the alpha and beta phase fields:

-

Copper (Cu) Content: approximately 57–60%

-

Microstructure: Primarily an alpha + beta two-phase structure, with the beta phase typically present in higher proportions than in H62. The beta phase is harder and more brittle.

Designation note: H59/H62 are Chinese GB/T 5231 wrought brasses. There is no one-to-one international equivalent. If you require an international grade, specify by Cu/Zn/Pb ranges and any special additions (e.g., As for DZR) rather than by name alone.

Mechanical and Physical Properties

The beta phase dictates H59’s mechanical behavior, which suits high-speed material removal:

-

Strength and Hardness: Marginally higher tensile strength and hardness compared to H62.

-

Ductility: Lower ductility and elongation.

-

Forming: Less suitable for complex cold forming processes.

Corrosion Resistance and Durability

H59 exhibits general resistance but has significant limitations in specific environments:

-

Overall: Adequate for dry, indoor, or non-critical applications.

-

Dezincification (DZR) Sensitivity: Highly susceptible to dezincification in water-contact, high-chloride, or ammonia-rich environments, compromising long-term durability.

Typical Applications

Due to its machinability and cost-efficiency, H59 is ideal for:

-

Cost-Sensitive, High-Volume Parts, where cycle time is the primary driver.

-

Automatic Lathe Parts due to excellent chip breakability.

-

Standard Components such as nuts, bolts, and simple bushings.

-

Non-Critical Pressure Parts in controlled environments.

What Is H62 Brass?

H62 brass, with a slightly higher copper content, offers a better balance of mechanical performance, corrosion resistance, and aesthetic consistency, making it a premium choice for specific applications.

hemical Composition

| Spec Item | H62 (Approx.) |

| Cu (wt.%) | 60.5–63.5 |

| Zn (wt.%) | 36–39.5 |

| Pb (wt.%) | trace / per order |

| Phase | alpha-dominant |

The composition of H62 keeps it closer to the alpha single-phase region:

-

Copper (Cu) Content: approximately 60.5–63.5%

-

Microstructure: Primarily an alpha single-phase structure with only a small amount of the beta phase, if any. The alpha phase is softer and more ductile.

Designation note: H59/H62 are Chinese GB/T 5231 wrought brasses. There is no one-to-one international equivalent. If you require an international grade, specify by Cu/Zn/Pb ranges and any special additions (e.g., As for DZR) rather than by name alone.

Mechanical and Physical Properties

The dominant alpha phase makes H62 more ductile and balanced:

-

Performance: Generally more balanced in strength and hardness than H59.

-

Ductility: Significantly better ductility and elongation.

-

Forming: Suitable for cold forming processes like bending and riveting.

Corrosion Resistance and Durability

H62’s higher copper and single-phase structure improve its long-term stability:

-

Long-Term Stability: More reliable for components intended for outdoor or long-life exposure.

-

Finishing: Easier to achieve consistent, high-quality surface finishes for electroplating.

Typical Applications

H62 is specified where long-term reliability and appearance are key:

-

Valve Bodies and Fittings in non-critical water or fluid systems.

-

Water Contact and Outdoor Parts, such as fixtures.

-

Decorative/Aesthetic Components requiring uniform polishing and consistent plating.

-

Precision Mating Parts where ductility aids in tolerance holding.

H59 vs H62: Side-by-Side Comparison

The choice between H59 and H62 often boils down to a trade-off between production efficiency/cost and corrosion resistance/surface quality.

Composition and Microstructure (alpha vs beta)

The key difference lies in the microstructure:

-

H59: The higher proportion of the brittle beta phase (alpha + beta) results in a harder material that naturally forms short, brittle chips during machining.

-

H62: The predominantly soft and ductile alpha phase ensures better elongation and formability but tends to produce tougher, longer, and stringier chips.

Mechanical Properties

| Property | H59 Brass | H62 Brass | Impact on Final Part and Processing |

| Strength/Hardness | Slightly Higher | Balanced / Slightly Lower | H59: Better for structural rigidity; H62: Better for cold forming. |

| Ductility (Elongation) | Lower (Brittle) | Significantly Higher | H59: Minimal cold working allowed; H62: Suitable for riveting, flaring, or light bending. |

Machinability

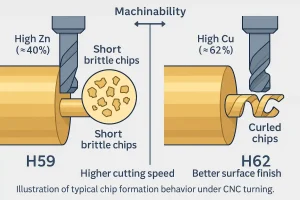

Illustration of H59 Brass (short chips, high speed) and H62 Brass (curled chips, better finish) chip formation in CNC machining.

This is arguably the most critical factor for CNC shops:

-

H59 (Chip Formation): Naturally forms short, small, and brittle chips that break easily. This is ideal for high-speed automated machining, requiring minimal chip-breaking strategies. It allows for higher speeds and feed rates to maximize Material Removal Rate (MRR).

-

H62 (Chip Formation): Tends to form longer, curled, and stringier chips (tougher alpha phase). Effective chip control is essential, requiring dedicated chip-breaking geometries or peck drilling cycles. While potentially slower, it is easier to achieve lower Ra values and tighter dimensional consistency.

Surface Finish and Electroplating

Surface quality is linked directly to the microstructure:

-

H62: The uniform alpha phase structure provides a more consistent, stable surface, leading to better adhesion and a more uniform appearance for subsequent electroplating (Nickel, Chrome).

-

H59: Acceptable finish is achievable, but the two-phase (alpha + beta) microstructure can lead to inconsistent etching during pre-plating chemical treatments, requiring stricter surface preparation.

Dezincification & Water Contact

H62 generally shows lower tendency to dezincification than H59 due to higher Cu and alpha-phase dominance; however, neither H59 nor H62 is a dedicated DZR grade. For sustained water contact (especially hot/soft/chlorinated water), specify a DZR brass (e.g., EN family CW602N / CuZn36Pb2As) or an equivalent per your standard. Confirm requirements (DZR, lead limits) in the PO/spec.

Cost and Material Supply

-

Cost Logic: The lower copper content of H59 generally results in a lower raw material cost. This is a major factor in high-volume production.

-

Availability: If you buy bar/rod/tube in standard stock sizes, both grades are commonly available; for tight custom dimensions, confirm mill lead time—H59 often trims raw-material cost, H62 reduces finishing risk.

H59 vs H62 Comparison Table

| Property | H59 (Cu ≈ 59%) | H62 (Cu ≈ 62%) |

| Composition (Cu/Zn) | Lower Cu | Higher Cu |

| Microstructure | alpha + beta (more beta) | Primarily alpha (less beta) |

| Machinability (Chips) | Excellent (Short, Brittle) | Good (Longer, Curled) |

| Ductility (Elongation) | Lower | Higher |

| DZR Susceptibility | High Susceptibility | Moderate Susceptibility |

| Surface/Plating Consistency | Acceptable | Better |

| Material Cost | Lower | Slightly Higher |

| Typical Use | High-volume Lathe Parts | Water/Outdoor Contact, Aesthetic Parts |

Compliance and Restrictions

Material selection must always adhere to regional regulatory compliance, particularly concerning public health and environmental restrictions.

Lead Content and Regional Rules

-

Compliance: For components in potable water or regulated consumer/industrial uses, confirm lead limits (e.g., US SDWA/NSF, EU directives, RoHS/REACH where applicable). Suitability depends on ordered chemistry and local rules. If low-lead is required, specify the lead limit and request compliance documentation.

-

Ordering: H59/H62 can be ordered in low-lead variants, but requirements must be stated in the drawing/PO (lead max, test/COC).

When to Require DZR

-

Risk: Long-term water contact (hot/soft/chlorinated), high-reliability plumbing, or coastal/chemical environments require higher resistance.

-

Specification: In these cases, specify a DZR grade (e.g., CW602N) or regional equivalent. Names and limits vary by standard, so procure by composition + DZR requirement rather than by name alone.

Process Recommendations for CNC Machining

The contrasting chip formation requires distinct CNC machining strategies for H59 and H62 to maximize efficiency and part quality.

Parameter Trends

-

H59 Strategy (Speed Priority): Capitalize on the short chip formation. Use higher spindle speeds and moderate to high feed rates to maximize MRR. Tool edges can be sharper, but ensure robust tooling to handle the mild impact wear from the breaking chips.

-

H62 Strategy (Surface Priority): Focus on chip control and stable material removal. Use moderate speeds and a consistent, slightly lower feed rate to control the stringy chip. Employ a slightly larger honing/micro-chamfer on the cutting edge to increase stability and minimize built-up edge (BUE). Aim for lower Ra values (e.g., Ra 0.8–1.6 microns) with dedicated finishing passes.

Program hints:

-

H59: Use higher speeds/medium-high feeds in roughing; finishing requires separate, more conservative parameters.

-

H62: Employ chip breaker geometries and light edge honing; finishing parameters should target the Ra 0.8–1.6 micron window.

Post-Machining Treatment (Stress Relief)

-

Recommendation: Brass is susceptible to Stress Corrosion Cracking (SCC) when internal residual stress is high and it is exposed to corrosive agents.

-

Post-Machining: A low-temperature stress relief anneal at 250–300 °C for 1–3 hours is strongly recommended for highly stressed H59 parts.

Chip Control and Coolant Usage Techniques

-

Coolant Flow: Always use generous, well-directed flow of water-miscible coolant to manage heat and aid chip evacuation.

-

H62 Chip Control: Due to the risk of long chips (swarf) entangling around the tool or workpiece, utilize dedicated chip-breaking grooves on the inserts, or incorporate a peck-drilling cycle to mechanically break the long chips.

Application and Selection Guide

The final decision should be made by overlaying the application requirements against the material properties.

Selection Based on Scenario

| Scenario | Recommended Grade | Why |

| High-Volume Automation | H59 | Short brittle chips maximize MRR and lower material cost. |

| Water/High-Humidity Contact | H62 (or DZR Grade) | H62 generally performs better than H59 in mild water exposure, but for long-term water contact a DZR grade is recommended. |

| Aesthetics/Electroplating | H62 | Finish consistency and superior plating adhesion. |

| Cold Forming/Riveting Needs | H62 | High ductility is required for post-machining deformation. |

| Tightest Cost Budget | H59 | Lower copper content translates to lower raw material cost. |

Conclusion

The choice between H59 and H62 brass is a balance of priorities:

-

H59: Opt for lower cost and highest production speed.

-

H62: Opt for better corrosion resistance, superior surface finish, and long-term reliability.

Send us your drawing and service environment specification. We will provide a comprehensive material recommendation (H59, H62, or DZR-grade), offer optimized CNC machining parameters, surface treatment plan, and a transparent cost and lead time quotation.

Contact Machining Minghe today to turn your brass design into a high-quality finished part.

The above content is for general engineering guidance. Specific applications must comply with local and regional regulations (e.g., lead restrictions) and be validated through application-specific testing.