End milling is a core CNC machining process that turns raw material into a precise finished product. This guide will walk you through the end milling process, from its fundamental principles to the tools, techniques, and common issues you’ll encounter along the way.

What is End Milling?

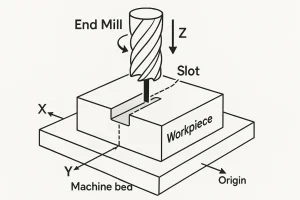

End milling is a cutting process that uses a rotating end mill to shape a workpiece. Unlike face milling, which is used to create a flat surface, end milling carves out a variety of complex features like slots, sidewalls, and contours. It’s one of the most versatile and widely used methods in CNC machining.

End Milling Process Flow

The end milling process is a systematic series of steps that transforms a digital design into a physical part, with each step specifically tailored to the unique nature of end milling.

Inspection and Post-Processing: Once machining is complete, the part is removed and inspected. End milling-specific features, such as the width of a slot or the depth of a pocket, are meticulously checked. Any final deburring or surface finishing is performed to complete the part.

Design and Programming: The process begins in CAD/CAM software. A skilled programmer defines the specific tool paths for features like pockets, slots, or 3D contours. This is where crucial end milling parameters like step-down (how deep the tool cuts in each pass) and step-over (how much the tool moves to the side in each pass) are determined to ensure efficient material removal and proper chip evacuation.

Machine and Workpiece Setup: The operator carefully secures the raw material onto the machine‘s workholding device, ensuring it can withstand the lateral cutting forces inherent in end milling. The selected end mill is then loaded into the spindle, and its exact position is calibrated to the workpiece’s origin.

Machining: This is the cutting stage, which often involves multiple passes to achieve the final shape.

Roughing: An aggressive cut that quickly removes the bulk of the material. This often uses a roughing end mill or a bull nose mill with a large step-down to clear the way for subsequent passes.

Finishing: A lighter, more precise cut that removes the remaining material, bringing the part to its final dimensions and desired surface finish. This often uses a flat end mill for sharp corners or a ball nose mill for smooth, contoured surfaces.

End Mill Materials

| Material | Grade | Tool Characteristics | Typical Applications |

| High-Speed Steel (HSS) | M2, M35 | Excellent toughness, strong resistance to impact. The tool is less likely to chip under unstable cutting conditions or vibration. It is also easy to resharpen. | Suitable for low-speed, interrupted cutting of mild steel, aluminum, etc., and when using machines with low rigidity. |

| Carbide | K10, K20, YL10.2 | Extremely high hardness, excellent wear and heat resistance. Can withstand high-speed cutting, has a long tool life, and achieves high precision and a superior surface finish. | Suitable for high-speed, high-efficiency, continuous cutting of stainless steel, tool steel, and hardened steel. |

| Powdered Metal HSS (PM HSS) | PM K390, PM M48 | Combines high toughness and high hardness. Its overall performance lies between HSS and Carbide, being more heat-resistant than HSS and more impact-resistant than Carbide. | Suitable for complex cutting conditions that require both high toughness and high wear resistance. A superior replacement for HSS. |

| Polycrystalline Diamond (PCD) | PCD grades (e.g., GE-PCD) | Unmatched hardness and wear resistance. The tool has an extremely long life, a very sharp cutting edge, and can achieve a mirror-like surface finish. | Specifically used for high-speed finishing of non-ferrous materials such as graphite, high-silicon aluminum alloys, and composites. |

| Cubic Boron Nitride (CBN) | CBN grades (e.g., BC-80) | Extremely high heat resistance. Maintains its cutting performance in a red-hot state. | Suitable for high-speed finishing of hardened steel, cast iron, and nickel-based alloys, especially for stable, continuous cutting. |

Types of End Mills

The variety of end mills available allows for incredible versatility in CNC machining. Each type is designed with a specific geometry to perform a particular task, from high-speed material removal to creating complex, detailed shapes.

General-Purpose End Mills

These are the most common tools you’ll encounter and are essential for a wide range of tasks.

- Flat End Mill: This is the workhorse of CNC machining. Its cutting edges run all the way to a flat end, making it perfect for milling 2D geometry. Use it to create flat surfaces, square-bottomed slots, and pockets with sharp corners.

- Ball Nose End Mill: With a rounded, spherical tip, this tool is the go-to for 3D contouring and surfacing. It’s used to create smooth, curved surfaces on molds, dies, and other complex parts, as its shape prevents step marks between passes.

- Bull Nose End Mill: Also known as a radius end mill, this tool has a flat bottom with a small radius at the corners. It combines the strengths of both flat and ball nose mills. The flat bottom is great for roughing out material, while the radius provides a stronger corner than a flat end mill, reducing the risk of chipping and extending tool life

Specialized End Mills

These tools are designed for specific, high-efficiency, or unique machining tasks.

- Roughing End Mill: This tool has a serrated or wavy cutting edge. Its design can break chips into smaller pieces more quickly, allowing for rapid removal of large amounts of material with less chatter and vibration. It is used for the initial, aggressive passes before a finishing tool is used

- Chamfer Mill: In the end milling process, a chamfer mill is used to mill precise chamfers or beveled edges on a workpiece. It is also commonly used for deburring and creating corner breaks to improve the quality of the finished part.

- Dovetail Mill: In the end milling process, a dovetail mill is a specialized form tool used for milling dovetail slots with a specific angle. This structure is often used to create dovetail slides on machines or for special interlocking connections on parts.

- T-Slot Cutter: This tool is specifically used to mill T-slots in the end milling process. It performs a lateral cut at the bottom of an already milled straight slot, creating a T-shaped channel on a machine bed or a part for clamping or securing a workpiece.

- Corner Rounding End Mill: This specialized tool is used to mill a precise concave radius on the edges of a part. It is the perfect choice for creating clean, rounded edges, which are often required for aesthetic and safety reasons.

The Pros and Cons of End Milling

Every machining process has its strengths and limitations. Understanding the pros and cons of end milling will help you choose the right process for your project.

- Pros

- Highly versatile: End milling can perform a wide range of tasks, including planar milling, pocketing, slotting, and complex contouring.

- High precision: With CNC programming, end milling can achieve high dimensional accuracy and tight tolerances.

- Excellent surface finish: When you use the right parameters and tools, end milling can produce outstanding surface quality.

- Wide material range: End milling works with almost any hard material, from plastics and aluminum to stainless steel and titanium alloys.

- Cons

- Tool wear: Because the cutting forces are concentrated on the tool, end mills wear out quickly and need to be replaced periodically.

- Machining time: Compared to forming processes like casting, end milling has a lower material removal rate, making it less efficient for large-scale production.

- Cost: High-end end mills and CNC equipment can be expensive, which affects the final machining cost.

Troubleshooting Common End Milling Issues

This section is for technicians who want to improve their troubleshooting skills.

- Excessive Tool Wear: This can be caused by an incorrect feed rate (F) or spindle speed (S). If the feed per tooth (fz) is too small, the tool will rub against the material instead of cutting, causing rapid wear. Using the right tool coating (like AlTiN) can also dramatically improve tool life.

- Poor Surface Finish: A rough surface is often a sign of a worn-out tool or a feed rate that’s too high. Using a sharp tool and a slower feed rate on the final pass will improve the finish.

- Vibration (Chatter): This is caused by unstable cutting conditions. Check if the tool is securely clamped or if it has too much overhang. You can also adjust the spindle speed and feed rate to find the sweet spot for a stable cut.

Frequently Asked Questions

What is an End Mill?

An end mill is a rotating cutting tool used on CNC machines and milling machines. Its core feature is that it has cutting edges on both the tip and the sides, allowing it to not only drill vertically but also cut sideways, efficiently removing material along a predetermined path. In short, if a drill bit is a tool for making holes, an end mill is like a high-speed carving knife that can move sideways to carve out a variety of complex shapes.

What is the difference between climb and conventional milling?

- Climb Milling: The tool’s rotation direction is the same as the feed direction. This method creates a smoother cut and better chip evacuation, which helps extend the end mill’s life and improve surface finish.

- Conventional Milling: The tool’s rotation direction is opposite to the feed direction. This can lead to more vibration and a rougher surface finish.

What are the most important end milling parameters?

The most important parameters are spindle speed (S), feed rate (F), and depth of cut. These three parameters collectively determine the load on the end mill and directly affect its life and the quality of the cut.

- Spindle Speed (S): Controls the rotational speed of the end mill. Choosing the right speed helps the tool maintain its optimal cutting temperature, preventing it from overheating or creating a built-up edge.

- Feed Rate (F): Controls the speed at which the end mill moves through the material. This, along with the spindle speed, determines the chip load, or the amount of material each tooth removes.

- Depth of Cut: This includes Axial Depth of Cut (ADOC) and Radial Depth of Cut (RDOC). These parameters determine the amount of material the end mill removes in each pass, directly affecting the cutting forces and tool stress.

How to Use an End Mill

Using an end mill involves a series of precise steps to ensure machining efficiency and part quality. The key is to master the following core points:

- Preparation and Setup: Based on the workpiece material and the required features, select the appropriate end mill type (e.g., flat end mill, ball nose end mill) and tool material (e.g., carbide). Securely clamp the workpiece to the machine and precisely calibrate the relative positions of the tool and the workpiece.

- Setting Cutting Parameters: This is crucial for determining the machining outcome. Based on the tool and workpiece material, you need to properly set the spindle speed (S), feed rate (F), and depth of cut (ADOC/RDOC) to balance cutting efficiency, tool life, and surface quality.

- Developing a Machining Strategy: To complete the job efficiently, a multi-step strategy is typically used. First, perform a roughing pass to quickly remove the bulk of the material, then use a finishing pass to achieve the final dimensions and desired surface finish.

- Monitoring and Adjustment: During the machining process, you should continuously monitor the cutting sound, chip formation, and tool wear. If any abnormalities occur, such as unusual noise or vibration, you should immediately stop and adjust the parameters to ensure safety and machining quality.

Conclusion

Achieving excellence in end milling requires a systematic mastery of the entire process. From the selection of the right tool for a specific material to the precise setting of operational variables that affect cutting performance, and the strategic planning of machining strategies to handle complex geometries—every single step directly determines the quality and efficiency of the final product. Mastery of these elements is the only way to achieve high-precision, high-efficiency manufacturing.

Begin Your Technical Partnership

In the face of complex and ever-changing manufacturing challenges, choosing the right tool is just the first step. MinHe is committed to becoming your technical partner, collaborating with you to explore how our professional end mills and process solutions can solve the core problems of your project.

Contact our expert team today and let us earn your trust through an in-depth technical discussion.