What is G-Code? The Core Language of CNC Programming

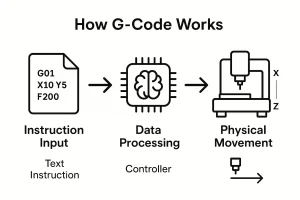

G-Code is the fundamental language of CNC (Computer Numerical Control) programming that controls machine movement. It’s a series of concise instructions telling the machine where to go, what path to take, and at what speed to move. In CNC machining, G-Code is the most vital part of any program because it directly dictates how the cutting tool interacts with the material to form the final part.

Where Does G-Code Come From?

G-Code’s history can be traced back to the 1950s at the Massachusetts Institute of Technology (MIT). At that time, engineers were looking for a way to automate machine tools to make manufacturing more efficient and precise. They developed a set of commands to control machine axes, which laid the foundation for G-Code as we know it today. Over the decades, this language has evolved and become the universal standard for CNC machines worldwide.

Common G-Code Commands by Type

G-Code commands can be classified into different types based on their function. Understanding these categories can help you organize and make sense of a G-Code program.

Motion Commands

These are the most fundamental G-Code commands, as they control the movement of the machine’s tool.

- G00 (Rapid Positioning): This command moves the tool to a specified position as fast as possible. It is used for non-cutting movements, such as when the tool needs to quickly move to its starting point.

- G01 (Linear Interpolation): G01 instructs the machine to move the tool in a straight line at a defined speed. It’s the most common command for cutting straight lines.

- G02 / G03 (Circular Interpolation): These commands move the tool in a circular path. G02 is for clockwise movement, while G03 is for counterclockwise. They are essential for machining features like holes and curves.

Preparatory and Tool Commands

These G-Codes set up the machining environment or prepare the tool for a task.

- G90 / G91 (Absolute / Incremental Programming): G90 sets the machine to work in absolute mode, where all coordinates are referenced from the origin point. G91 sets the machine to work in incremental mode, where each coordinate is referenced from the tool’s current position.

- G04 (Dwell): G04 is a programmed pause. It is often used to allow the spindle to reach its full speed before cutting or to give the tool time to clear chips.

- G40 / G41 / G42 (Cutter Compensation): These commands are used to adjust the tool path to compensate for the tool’s radius or length, ensuring high-precision machining.

Canned Cycles

Canned cycles are a type of G-Code that combines a series of complex machining steps (like drilling a hole) into a single, simple command. They are used to save time and simplify programming.

Practical Applications of G-Code

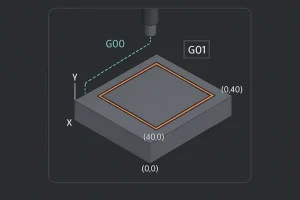

G-Code makes it possible to create complex and precise parts that are difficult to make by hand. Below is a simple example showing how G-Code works in a real-world scenario.

Let’s assume we want to cut a 40mm x 40mm square on a workpiece.

- G90: Set to absolute coordinates

- G00 X0 Y0 Z5: Rapid move to the start point (0,0,5), with the Z-axis at a safe height

- G01 Z-2 F100: Cut down along the Z-axis, feed rate 100 mm/min

- G01 X40 F200: Cut along the X-axis to X=40

- G01 Y40 F200: Cut along the Y-axis to Y=40

- G01 X0 F200: Cut back along the X-axis to X=0

- G01 Y0 F200: Cut back along the Y-axis to Y=0

- G00 Z5: Rapid move up to a safe height

- M30: End of program

By understanding each line of this code, you can see how simple commands combine to complete a full cutting task. You can visualize the tool starting at one point, following a precise coordinate path step by step, and ultimately finishing a perfect square.

Benefits of Using G-Code

Using G-Code offers several key advantages in manufacturing:

- High Precision: G-Code allows for digital control over every movement, ensuring parts are made with incredible accuracy and consistency.

- Efficiency: Once a G-Code program is written, a CNC machine can run continuously, which speeds up production and reduces labor costs.

- Complexity: G-Code makes it possible to create intricate and complex geometries that would be difficult or impossible to produce with traditional, manual machining methods.

Who Should Learn G-Code?

Learning G-Code is essential for several professionals in the manufacturing and engineering fields. First and foremost, CNC machinists and operators must understand G-Code to read, edit, and troubleshoot programs directly on the machine. This knowledge is crucial for making quick adjustments and ensuring part accuracy. Manufacturing engineers should also have a strong grasp of G-Code to design efficient processes and communicate effectively with the shop floor. Finally, product designers and CAD/CAM technicians can benefit from learning G-Code, as it gives them a deeper understanding of how their designs will be physically produced, allowing them to create parts that are easier and more cost-effective to machine.

What Machines Use G-Code?

G-Code is the universal language of CNC (Computer Numerical Control) machining, so it is used across a wide range of automated manufacturing equipment.

CNC Mills

CNC mills are the most common application of G-Code. They use a rotating cutting tool to move along the XYZ axes, shaping material to create complex parts. G-Code programs precisely control every movement of the tool to ensure the part’s accuracy and quality.

CNC Lathes

Unlike mills, lathes primarily cut material by rotating the workpiece. They are used for making cylindrical parts like shafts and nuts. Here, G-Code controls how the cutting tool approaches, moves, and exits the spinning workpiece.

3D Printers

While 3D printers are additive manufacturing machines, they also rely on G-Code. G-Code tells the print head where to move in three-dimensional space, at what speed to move, and how much material to extrude, building the object layer by layer.

Laser and Plasma Cutters

These machines use G-Code to control the path and speed of the cutting head to precisely slice through metal sheets. G-Code ensures the cut lines are smooth and accurate, which is crucial for creating metal parts or art.

Robotic Arms

In automated production lines, many robotic arms also use G-Code to control their complex movements for tasks like welding, gluing, assembly, and painting. The precision of G-Code allows robots to repeatedly perform highly intricate operations.

How to Write G-Code: From Blueprint to Code

Writing G-Code is the process of translating a part’s design into a set of instructions that the machine can understand. While modern CAD/CAM software can automate this process, understanding the basics of G-Code is crucial for troubleshooting and optimizing machining processes.

Choosing the Right Programming Tool

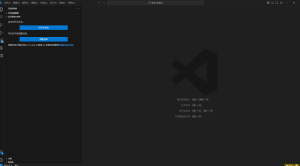

While you can write G-Code using any text editor, professional G-Code editors offer features specifically designed for CNC programming. These tools can dramatically improve efficiency and reduce errors.

Here are a few popular G-Code editors:

- VS Code (Visual Studio Code): This is a powerful, free code editor. By installing a relevant extension (like

G-Code Syntax), you can enable syntax highlighting and auto-completion, turning it into an excellent G-Code editor. - NC Viewer: This is a convenient, free online tool. Just copy and paste your G-Code, and it will immediately visualize the tool path. This is a great way to check for potential errors before you run the program.

- Fusion 360: Besides being a robust CAD/CAM software, Fusion 360 includes a built-in G-Code editor. This lets you design a part, generate the tool path, and edit the G-Code all within one program.

Five Basic Steps to Writing G-Code

- Program Header: Every G-Code program starts with a program number (O + a number). At the beginning of the program, you typically set the work plane (e.g.,

G17) and select either absolute or incremental coordinates (G90orG91). - Safe Movement: Use G00 to rapidly move the tool to a safe position above the workpiece. This ensures there are no collisions before cutting begins.

- Cutting Into the Material: Use G01 to move the tool down along the Z-axis to the desired cutting depth. Make sure to set a proper feed rate.

- Cutting the Part’s Profile: Use G01 (for straight lines) and G02/G03 (for arcs) to cut the part’s profile. You must specify the endpoint coordinates (X, Y, Z) and the feed rate for each movement.

- Program End: When all cutting is complete, use G00 to rapidly retract the tool. Then, use commands like M30 to end the program and reset the machine to its starting position.

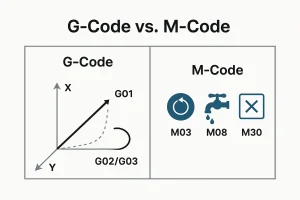

G-Code vs. M-Code: A Clear Difference

Although G-Code is the core of CNC programming, it is not the only type of instruction. In a CNC program, it often works together with M-Code (short for Miscellaneous Function). G-Code primarily controls motion, telling the machine how to move and cut. M-Code, on the other hand, controls the non-motion functions of the machine, such as turning the spindle on or off (M03/M05), turning the coolant on or off (M08/M09), and ending the program (M30). You can think of G-Code as the instructions for what to do, while M-Code is the supplementary instruction for how to do it. Together, they form a complete CNC programming language.

Frequently Asked Questions (FAQ)

Is G-Code hard to learn?

For beginners, the basics of G-Code are not difficult to learn. Many of the most common commands are intuitive and easy to remember. However, becoming an expert who can write complex programs from scratch requires a lot of practice and a deeper understanding of geometry and machining principles. The best way to start is by mastering the core commands and practicing with simple projects.

Why should I learn G-Code if I can just use CAM software?

While modern CAM (Computer-Aided Manufacturing) software can automatically generate G-Code, understanding its fundamentals is still crucial. A strong grasp of G-Code allows you to quickly troubleshoot problems, optimize programs, and make on-the-fly edits directly at the machine, saving you significant time and effort and giving you greater control over the machining process.