Among all surface finishing methods for aluminum, anodizing is one of the most robust and versatile techniques. It not only enhances corrosion resistance and surface hardness but also provides a wide range of metallic colors through dyeing. Yet, one of the most common and critical questions engineers and designers pose is: How long does anodizing actually last in service?

The answer is not a fixed number; it is contingent upon multiple factors, including the anodizing type, coating thickness, environment, and maintenance practices.

What Determines the Lifespan of Anodizing

It is crucial to understand that anodizing is fundamentally not a coating applied to aluminum—it is an electrochemical conversion process. During this process, the surface of the aluminum reacts with oxygen in an electrolytic bath to form an integral layer of aluminum oxide (Al2O3).

This oxide film is chemically integral to the base metal, meaning it cannot peel or flake off like paint or traditional plating.

Several key factors critically influence how long the anodized finish endures:

| Factor | Description | Impact on Lifespan |

| Oxide Thickness | Thicker layers provide a superior physical barrier. | Directly increases longevity. |

| Sealing Quality | Professional sealing prevents moisture and salt penetration into pores. | Critical for long-term corrosion resistance. |

| Alloy Composition | High silicon or copper content reduces the uniformity of the film. | Decreases overall durability. |

| Surface Preparation | Etching and polishing steps affect film adhesion and structure. | Determines uniform coating consistency. |

| Environment | Humidity, UV radiation, acid rain, and salt exposure. | Accelerates natural degradation. |

| Mechanical Wear | Abrasion, friction, or impact can locally erode the oxide. | Shortens lifespan locally. |

In general, thicker and properly sealed coatings will consistently last for decades in mild environments without visible degradation.

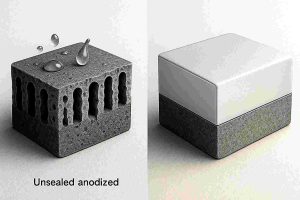

3D visualization comparing unsealed porous anodized surface with fully sealed anodized layer for corrosion protection.

Types of Anodizing and Their Lifespan

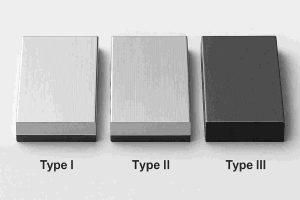

According to the MIL–A–8625F standard, anodizing is classified into three main types. Each is engineered to deliver distinct performance characteristics and corresponding service life.

Type I, Type II, and Type III anodizing comparison – illustrating variation in coating thickness and durability.

Type I – Chromic Acid Anodizing

-

Thickness: 2.5–7.5 μm

-

Features: Thin, highly flexible film with minimal dimensional change.

-

Protection: Basic corrosion resistance.

-

Typical Lifespan: 5–15 years

-

Applications: Aerospace and precision assemblies (where dimensional control is paramount).

Type II – Sulfuric Acid Anodizing

-

Thickness: 5–25 μm

-

Features: Cost-effective, readily dyeable, ideal for decorative appearance.

-

Protection: Good corrosion and wear resistance.

-

Typical Lifespan: 10–30 years (highly dependent on sealing and environment).

-

Applications: Architectural panels, consumer appliances, and electronics housings.

Type III – Hard Anodizing (Hardcoat)

-

Thickness: 25–100 μm

-

Features: Exceptionally hard (HV 400–600), maximum wear and corrosion resistance.

-

Protection: Excellent, even under severe and harsh conditions.

-

Typical Lifespan: 30–60 years or longer

-

Applications: Industrial, automotive, marine, and military components.

Summary: Type I prioritizes precision; Type II balances appearance and cost; Type III is engineered for maximum durability in demanding applications.

Testing Standards and Performance Data

In industry, the projected lifespan of anodizing is rigorously assessed through accelerated testing standards:

| Test Method | Standard | Test Conditions | Performance Metric |

| Salt Spray Test | ASTM B117 | 35∘C, 5% NaCl solution | Hours without base metal corrosion |

| Humidity Resistance | ISO 9227 | 95% RH, 40∘C | Color and gloss retention |

| UV Aging Test | ASTM G154 | UVA−340 lamp | ΔE (Color change) |

| Abrasion Resistance | ASTM D4060 | CS−17 wheels, 1000 g load | Weight loss in mg |

Performance Benchmarks: A standard 25 μm Type II coating typically withstands 500–1000 hours of salt spray without corrosion, whereas Type III coatings often exceed 3000 hours—a performance level that translates to decades of outdoor service.

Lifespan in Different Environments

| Environment | Recommended Type | Expected Lifespan | Notes |

| Indoor (Dry, Stable) | Type II | 40–50+ years | Requires minimal maintenance. |

| Outdoor (General Exposure) | Type II / III | 20–40 years | Regular cleaning is strongly recommended. |

| Industrial (Polluted, Acidic) | Type III | 30–50 years | High durability is required under chemical exposure. |

| Marine (Salt Spray) | Type III | 40–60+ years | Must use high-quality sealed or wax-coated surface. |

| Aerospace / Precision Parts | Type I | 5–15 years | Lifespan dictated by dimensional accuracy needs. |

Field data confirms that anodized architectural panels installed as far back as the $\text{1970}$s remain largely intact after over 40 years. In contrast, unsealed or poorly maintained aluminum in aggressive coastal regions can show significant chalking or pitting within 10 years.

Degradation and Aging Mechanisms

Over time, even the highest quality anodized layers undergo slow changes. The main degradation mechanisms include:

-

Moisture Absorption: Poorly sealed coatings absorb water, causing loss of gloss or slight swelling.

-

UV Fading: Organic dyes break down under UV exposure, leading to color shift or fading.

-

Pitting Corrosion: Salt and pollutants penetrate open pores and create localized corrosion.

-

Abrasive Wear: Sliding contact or dust gradually thins the oxide layer, exposing the base metal.

Hard anodizing (Type III) significantly delays these effects due to its dense, non-porous structure.

Engineering Recommendations to Extend Lifespan

-

Specify adequate thickness: ≥10 μm for indoor, ≥20 μm for outdoor, must be ≥40 μm for marine or industrial use.

-

Use high-quality sealing: Nickel acetate or PTFE sealing improves salt-spray resistance by up to 50%.

-

Avoid galvanic corrosion: Isolate aluminum from copper or steel using non-metallic spacers.

-

Clean regularly: Neutral detergent and soft cloths help remove deposits.

-

Re-seal aged surfaces: Hot-water resealing can restore surface integrity and extend life.

With proper design and care, anodized aluminum can retain its function and finish for half a century or more.

Real-World Examples

-

Architecture: Many anodized façades from the $\text{1970}$s still exhibit clean metallic surfaces after 45 years of exposure.

-

Automotive & Machinery: Hard-anodized pistons and hydraulic cylinders maintain performance after millions of cycles.

-

Marine Equipment: Dual-sealed Type III housings survive over 4000 hours of salt-spray testing—roughly equivalent to 40–50 years in real-world conditions.

These examples demonstrate that anodizing’s longevity is not a theoretical assumption; it is proven by decades of industrial experience.

Comparing Anodizing with Other Finishes

| Surface Treatment | Typical Lifespan | Corrosion Resistance | Wear Resistance | Environmental Impact |

| Anodizing (Type III) | 30–60 years | ★★★★★ | ★★★★★ | Non-toxic, no heavy metals |

| Nickel-Chrome Plating | 10–20 years | ★★★★ | ★★★★ | Contains heavy metals |

| Powder Coating | 10–15 years | ★★★ | ★★★ | May peel or crack over time |

| Anodizing + Clear Sealant | 40–70 years | ★★★★★ | ★★★★★ | Excellent all-around protection |

Anodizing stands out for combining longevity, hardness, and environmental safety—making it the premier choice for aluminum protection.

Conclusion

The lifespan of anodized aluminum ranges from 10 to over 60 years, depending on its type, thickness, and maintenance. Unlike paint or plating, anodizing does not merely coat the surface—it fundamentally transforms its structure.

With proper sealing and periodic care, anodized parts can remain both functional and visually appealing for generations.

For manufacturers and engineers seeking durable, sustainable, and aesthetically consistent aluminum finishes, anodizing remains the gold standard for long-term performance and protection.

If you want to enhance the lifespan and appearance of your aluminum components, contact our surface treatment experts today—we’ll help you select the right anodizing type and specifications for your next project.