In traditional manufacturing, the cutting of complex sheet metal profiles often relies on expensive tooling for stamping or mechanical shearing, leading to a lack of cost-effectiveness and flexibility in low-volume, high-iteration environments. When dealing with high-strength materials or parts requiring fine features, mechanical cutting risks introducing stress concentrations and deformation, compromising final assembly precision. A non-contact, highly versatile processing solution that balances design freedom, cutting speed, and edge quality is essential for modern mechanical design. Laser cutting technology addresses this need by utilizing high-energy density light to achieve precise, efficient, and stress-free separation of virtually all industrial materials, offering a revolutionary path to optimizing design and manufacturing workflows.

What is Laser Cutting

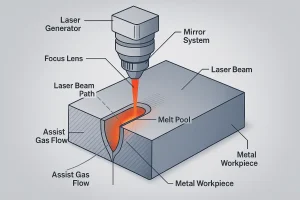

Laser cutting is an advanced thermal separation process that removes material through a highly focused beam of intense light energy. The core principle involves a laser generator producing a monochromatic, coherent, and highly directional light beam. This beam is then transmitted and concentrated by an optical system, such as focusing lenses, to an extremely small focal spot, resulting in a colossal energy density.

Schematic of the laser welding process highlighting the beam path and molten pool formation.

When the concentrated light spot impacts the workpiece surface, the material rapidly absorbs the energy, causing its temperature to spike immediately above the melting or boiling point. Depending on the material and the assist gas used, the removal mechanism is primarily categorized into: Fusion Cutting, where an inert gas (like Nitrogen) blows the molten material away; Vaporization Cutting, where the material directly turns into a gas and is ejected; and Flame/Oxidative Cutting, where an active gas (like Oxygen) is used to create an exothermic reaction that aids in melting and accelerates the cutting process. In modern industrial applications, Fiber Lasers and CO₂ Lasers are the dominant sources, with fiber lasers increasingly preferred for metal processing due to their superior beam quality and electrical efficiency. Precise CNC motion systems ensure the laser spot accurately follows the programmed path to complete the high-quality contour cut.

Core Advantages

Laser cutting technology fundamentally shifts manufacturing capabilities by delivering predictable outcomes and operational efficiencies critical for engineering decisions. The following result-based advantages highlight the process’s value.

High Precision and Dimensional Accuracy

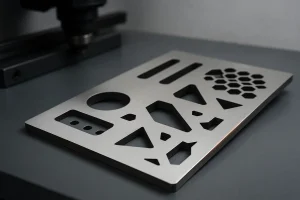

The minute focus point of the laser beam allows for a very narrow kerf, directly translating into high geometric precision and the ability to realize intricate features. Since the process is non-contact, mechanical distortion from clamping or cutting forces is eliminated. This ensures superior dimensional consistency and part integrity, which is essential for components requiring tight assembly tolerances.

Faster Turnaround and Productivity Gains

Laser cutting excels in speed, particularly with medium-to-thin sheet materials, significantly reducing the cycle time per part compared to most mechanical methods. Paired with high-density nesting and easy integration with automated material handling systems, this process achieves high throughput and minimizes manual intervention. This automation potential and speed compress lead times, leading to rapid turnaround for both prototypes and large batches.

Lower Overall Production Cost

The combination of several factors drives down the Total Cost of Ownership (TCO). Minimal kerf width maximizes material utilization, particularly valuable for expensive alloys. Furthermore, the high quality of the cut edge often eliminates or drastically reduces the need for secondary finishing operations like deburring or grinding. This simplification of the post-processing chain directly lowers labor and operational costs.

Design Flexibility and Process Versatility

Laser cutting is inherently tool-less, allowing for immediate production changes without the delay or expense of new tooling. This high degree of flexibility supports complex design iterations and custom one-off parts with ease. Its process is highly adaptable across nearly all industrial materials—from standard carbon steel to reflective copper—and supports a wide range of thicknesses, offering a single solution for diverse manufacturing needs.

Material and Thickness Capabilities

| Category | Typical Laser Type | Common Materials | Key Process Notes |

|---|---|---|---|

| Metals | Fiber laser | Carbon steel, stainless steel, aluminum, copper alloys | High efficiency; nitrogen fusion cutting ensures oxide-free edges; thickness up to 20 mm+ |

| Non-metals | CO₂ laser | Acrylic, wood, polymers, textiles, composites | Vaporization / ablation cutting; requires thermal control to minimize HAZ |

Fiber lasers dominate modern metal cutting due to superior beam quality and electrical efficiency, while CO₂ lasers remain the reliable choice for non-metallic materials where smooth edges and minimal charring are critical.

Cost and Efficiency Comparison

When selecting a cutting process, engineers must directionally compare laser cutting against other common technologies across the metrics of cost, speed, and quality.

Versus Waterjet Cutting: Waterjet is a cold cutting process, eliminating the HAZ and suitable for all materials. However, laser cutting is significantly faster for thin sheet metal and typically has lower operational and maintenance costs. Waterjet offers better edge perpendicularity on very thick parts, but at the expense of speed and high abrasive consumption costs.

Versus Plasma Cutting: Plasma cutting is cost-effective and fast for thick metal plates. Conversely, laser cutting offers far superior precision, edge quality, and a smaller HAZ. Plasma is preferred for heavy structural components where tolerance requirements are looser, while laser is the definitive choice for high-precision, medium-to-thin gauge applications.

Versus CNC Milling or Stamping: Stamping is cheapest for very high volumes of simple parts but requires high initial tooling investment. CNC milling achieves the highest precision but is slow due to low material removal rates and incurs tool wear costs. Laser cutting provides the best balance of flexibility, speed, and precision, particularly for prototyping, low-to-medium volume runs, and parts with complex geometries, leading to a favorable Total Cost of Ownership (TCO).

Applications

Laser cutting technology’s versatility, combined with its accuracy and speed, has made it a foundational process across numerous mission-critical industries:

Example of a precision laser-cut metal sheet demonstrating clean edges and design flexibility.

- Sheet Metal Fabrication: Used extensively for manufacturing machine enclosures, structural frames, brackets, and customized component parts.

- Automotive Manufacturing: Employed for the precise cutting of body-in-white structural parts, airbag components, and intricate interior elements.

- Aerospace: Used for processing complex components from high-performance alloys (e.g., Titanium, Inconel), where extremely tight tolerances and high surface integrity are mandatory.

- Electronics and Semiconductor: Essential for micro-cutting thin metal foils, precise circuit board stencils, and intricate electronic device housings.

- Medical Devices: Manufacturing high-precision surgical instruments, brackets, and miniature implantable components from stainless steel and titanium alloys.

Conclusion

Laser cutting stands as an indispensable and continually advancing technology within modern precision manufacturing. It provides an efficient, adaptable, and quality-controlled solution that empowers mechanical design engineers to realize complex geometry, enables manufacturing engineers to streamline production workflows, and assists procurement managers in securing high-value, cost-effective custom parts. It has successfully resolved critical limitations associated with traditional separation methods, fostering a tighter integration between design intent and manufactured reality.

To ensure your design is manufactured with optimal cost and quality, upload your CAD drawings or technical specifications. Our engineering team will provide a professional review and a precise quotation.