As two of the most widely used joining processes in modern manufacturing, riveting and welding each offer unique characteristics while sharing the common goal of providing a stable and reliable permanent connection. Since different applications have varying requirements for strength, weight, and material properties, understanding the core differences between these two methods is essential. Below, we will delve into the technical principles of riveting and welding and their specific applications in engineering.

What is Riveting?

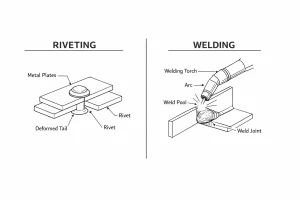

Riveting is a permanent fastening method that relies on mechanical locking. The basic principle involves pre-drilling holes in the parts to be joined, inserting a metal pin (the rivet), and then applying pressure or impact to deform the end of the rivet, forming a second “head” that locks the parts together. Because this process does not involve melting materials, it is considered a cold-working process.

Types of Rivets

To adapt to different structural requirements and installation environments, engineers have developed various types of rivets. The following are the most common types used in industry:

- Solid Rivets: The most traditional and reliable type, usually requiring access to both sides of the material; widely used in high-stress structures like bridges and aerospace frames.

- Blind Rivets (Pop Rivets): These can be installed with access to only one side of the assembly, making them ideal for tubing or closed structures where the back side is unreachable.

- Self-Piercing Rivets (SPR): These do not require pre-drilled holes; they are driven through the top layer and flared into the bottom layer under high pressure, a standard in modern automotive aluminum body production.

- Huck Bolts: These use a specialized collar that is swaged into grooves on the bolt, providing extremely high clamping force and vibration resistance for heavy-duty truck chassis.

Pros and Cons of Riveting

When evaluating if riveting is suitable for your project, you must weigh its unique mechanical properties against its physical limitations:

Advantages of Riveting

- Joining Dissimilar Materials: It can easily join combinations that are difficult to weld, such as aluminum to steel, plastic to metal, or composites.

- No Thermal Damage: As a cold process, it produces no Heat Affected Zone (HAZ), perfectly preserving the original physical properties of the parent material.

- Superior Vibration Resistance: Riveted joints possess a degree of toughness/flexibility, making them less prone to fatigue cracking than welds in environments with constant vibration (like aircraft wings).

Disadvantages of Riveting

- Increased Weight: Rivets themselves add weight, and the necessary overlapping of joints increases the total amount of material used.

- Structural Weakening: Holes must be drilled, which reduces the cross-sectional area of the parent material and creates stress concentration points.

- Sealing Issues: Riveted joints are not naturally airtight or watertight and usually require the application of separate sealants.

What is Welding?

Welding is a metallurgical joining process that achieves a bond at the atomic level between two metal parts through the use of heat, pressure, or both. It melts the base metals or a filler material, which then cools to form a continuous, unified whole.

Types of Welded Joints

When selecting a welding process, the design of the joint is as critical as the welding method itself. Depending on the relative positions of the parts and the load requirements, welded joints are categorized into five basic types:

- Butt Joint: The edges of two parts are brought together in the same plane; this is the most effective joint for resisting pressure and tension.

- Lap Joint: Two parts are partially overlapped and joined at the edges; commonly used for connecting thin sheets.

- Corner Joint: Two parts meet at an angle (usually 90°) to form an “L” shape, frequently used in box or frame structures.

- T-Joint: The end of one part is placed perpendicular to the surface of another to form a “T” shape; it is a common support connection in structural engineering.

- Edge Joint: The parallel edges of two parts are placed in contact and welded together; typically used for reinforcing the edges of thin plates not subject to heavy loads.

Pros and Cons of Welding

While pursuing structural integration and ultimate strength, welding offers massive advantages but also introduces challenges in thermal management:

Advantages of Welding

- Extreme Strength: The strength of a welded joint can often equal or exceed the strength of the base material itself, creating a true monolithic structure.

- Lightweight Design: No extra fasteners or large overlapping areas are needed, making it the most effective method for structural weight reduction.

- Perfect Sealing: Provides a continuous physical bond that is naturally airtight and watertight, essential for pressure vessels and piping.

Disadvantages of Welding

- Thermal Distortion Risk: The high-heat cooling process causes material contraction, which can lead to structural warping or internal residual stress.

- Irreversibility: Welding is a permanent bond; disassembly usually requires physical destruction of the parts.

- High Environmental Sensitivity: Requires extreme cleanliness and is restricted in flammable/explosive environments; requires highly skilled operators.

Comparison Between Riveting and Welding

To more intuitively understand the differences between the two processes, the table below provides a comprehensive comparison across multiple technical dimensions:

| Feature | Riveting | Welding |

| Joining Mechanism | Mechanical Fastening | Metallurgical Fusion |

| Sealing Performance | Poor (Requires sealant) | Excellent (Naturally airtight) |

| Weight Impact | Heavier (Fasteners + Overlap) | Lighter (No extra weight) |

| Material Limits | Very Few (Dissimilar materials) | Significant (Compatible metals only) |

| Environment | Adaptable (Cold working) | Strict (Fire/Wind/High voltage) |

Once the basic attributes are clear, we need to further distinguish their roles in heavy engineering through specific strength performance and failure mechanisms:

1. Joining Mechanism

Riveting relies on mechanical locking through physical deformation without melting the base materials. Welding, however, utilizes metallurgical fusion, where high heat fuses atoms together to create a single, continuous structure.

2. Sealing Performance

Welding is naturally superior for airtight or watertight applications due to its seamless bond. Riveting leaves microscopic gaps between parts, often requiring secondary sealants to ensure a leak-proof joint.

3. Weight Impact

Welding creates lighter structures by eliminating the need for fasteners and excessive material overlap. Riveting adds weight through the hardware itself and requires larger overlap areas for a secure connection.

4. Material Limits

Riveting excels at joining dissimilar materials like aluminum-to-steel or composites. Welding is restricted to compatible metals and requires careful management to prevent structural issues in heat-sensitive alloys.

5. Environmental Requirements

Riveting is a robust process suitable for harsh or outdoor conditions. Welding requires a controlled environment to ensure fire safety and consistent shielding gas coverage, making it sensitive to external factors.

Common Questions FAQ

Why are planes riveted instead of welded?

The aluminum alloys used in aircraft are highly sensitive to heat, and welding would significantly reduce material strength. Furthermore, airframes experience intense vibration and pressure cycles during flight; riveting provides the structural toughness and fatigue resistance needed, which is superior to a rigid weld.

Which is stronger: Brazing or Welding?

Generally, traditional fusion welding (like arc welding) is stronger because it fuses the base metals together. Brazing relies on the filler metal wetting the surface; its strength depends largely on the surface area of the joint design.

Is riveting cheaper than welding?

Not necessarily. While welding equipment has a higher upfront cost, it is highly automatable. The riveting process involves drilling, alignment, and manual installation, which can lead to higher labor and consumable costs in mass production.

Is the strength of riveting the same as welding?

No. Welding usually wins in static tensile strength, but riveting often proves more durable when subjected to repetitive, dynamic loads over a long period.

Are rivets permanent or temporary?

Rivets are permanent fasteners. While they can be removed by drilling out the head, this is considered destructive disassembly, unlike bolts which can be removed and reused without damage.

Conclusion

Choosing between riveting and welding is essentially a balance between “Vibration Resistance & Toughness” (Riveting) and “Strength & Efficiency” (Welding). If your product involves dissimilar materials or complex vibration environments, riveting is your best choice. If you seek ultimate lightweighting and full sealing performance, welding is the optimal solution.

Looking for the best joining solution for your project?

Our technical team provides customized process assessments to ensure your product achieves the optimal balance between performance and cost. Contact an expert for a free process evaluation now