Flange Connections: Principles, Types, and Where They Are Used

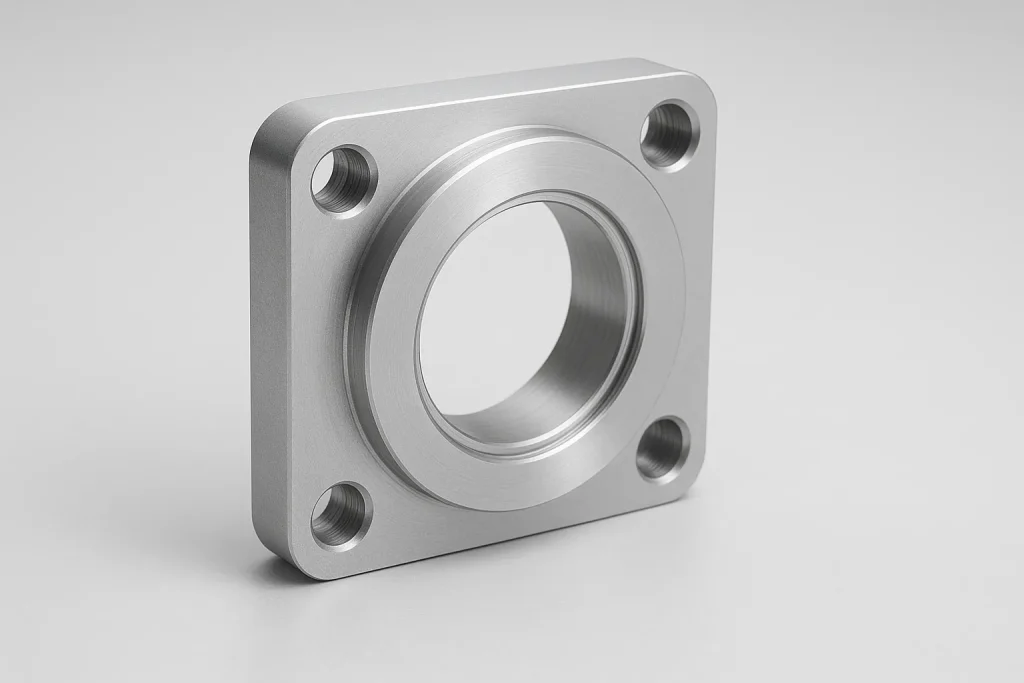

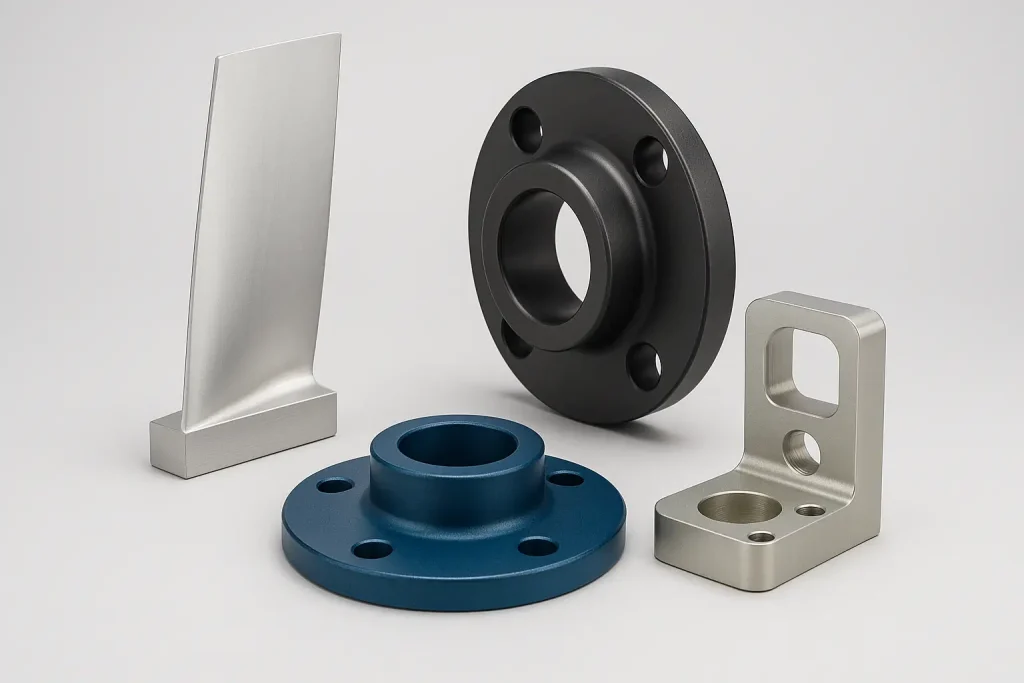

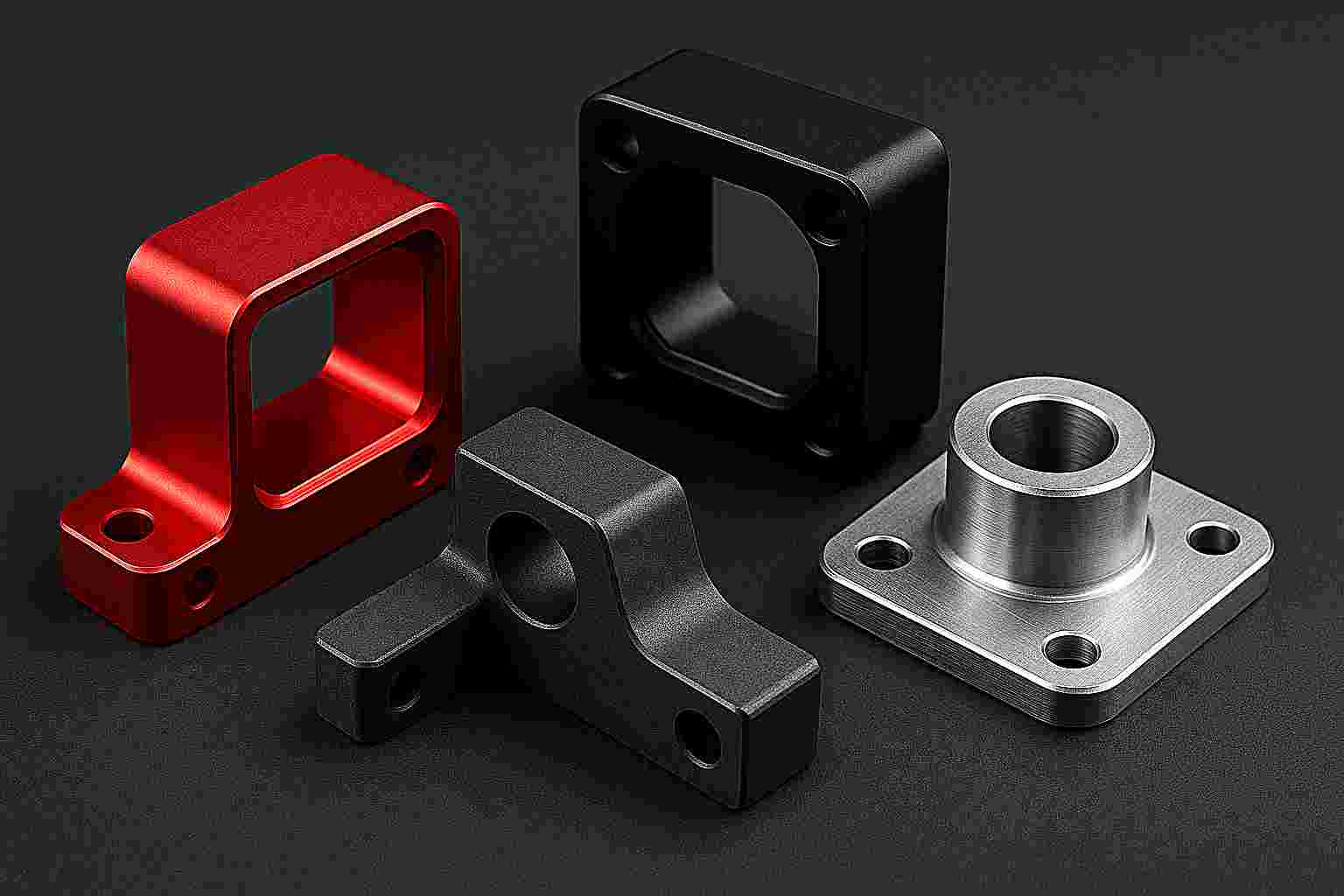

A flange is a key mechanical connector used to join pipes, valves, pumps, and equipment in industrial systems. It allows reliable, leak-free connections that can be easily assembled, disassembled, and maintained. This article provides a comprehensive overview of flange fundamentals—including structure, types, facing forms, pressure ratings, standards, and dimensional parameters. It explains how different flange designs (such as weld neck, slip-on, and blind types) meet specific pressure and temperature conditions, and highlights the importance of standardization and correct gasket selection for safe, durable sealing performance.