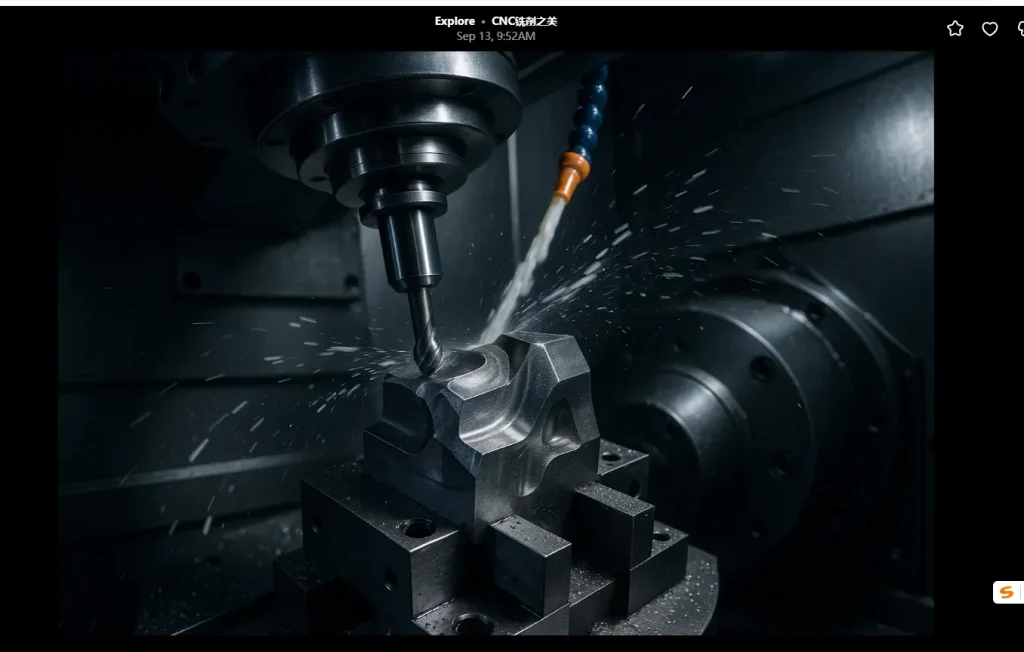

Customized CNC Milling Solutions

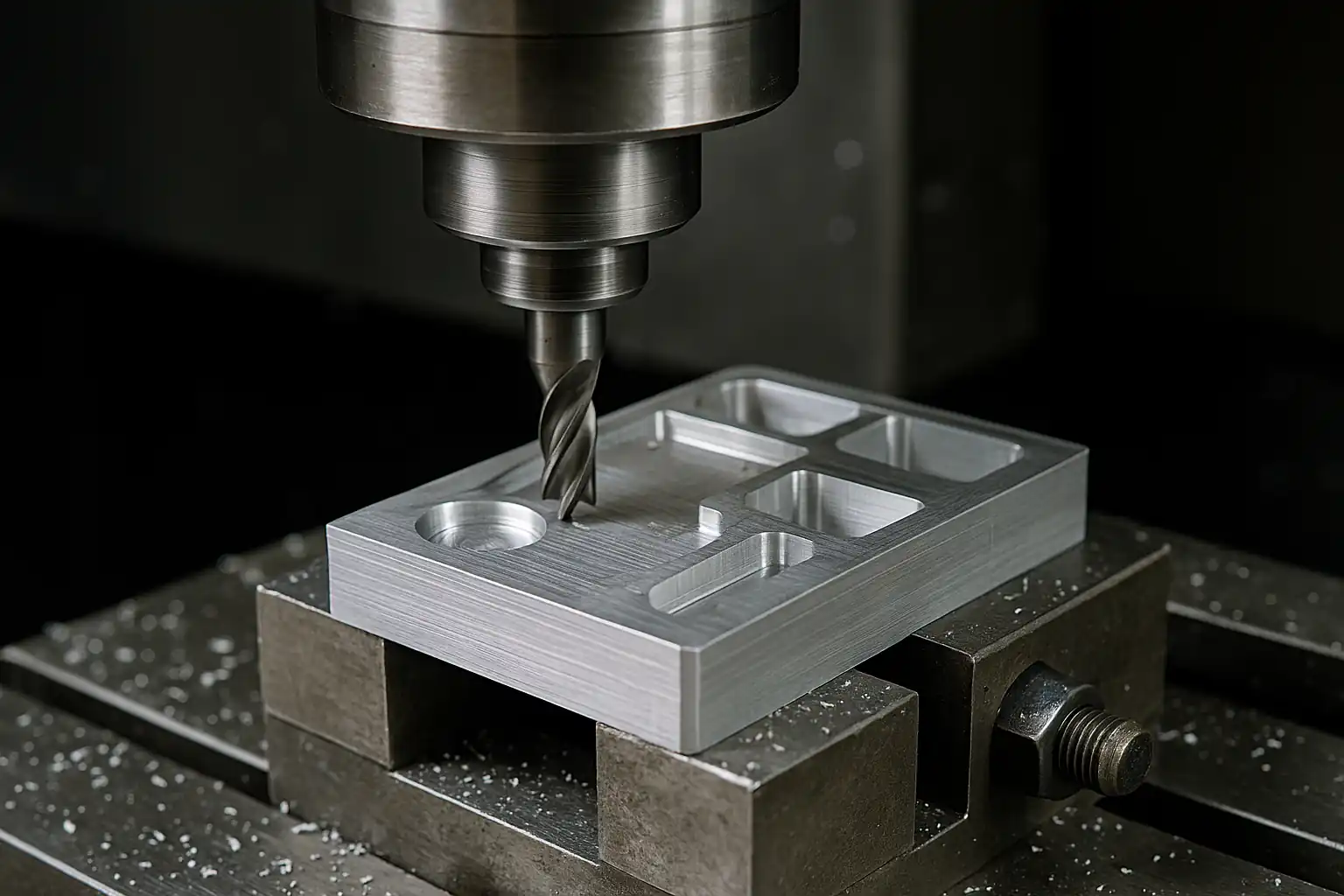

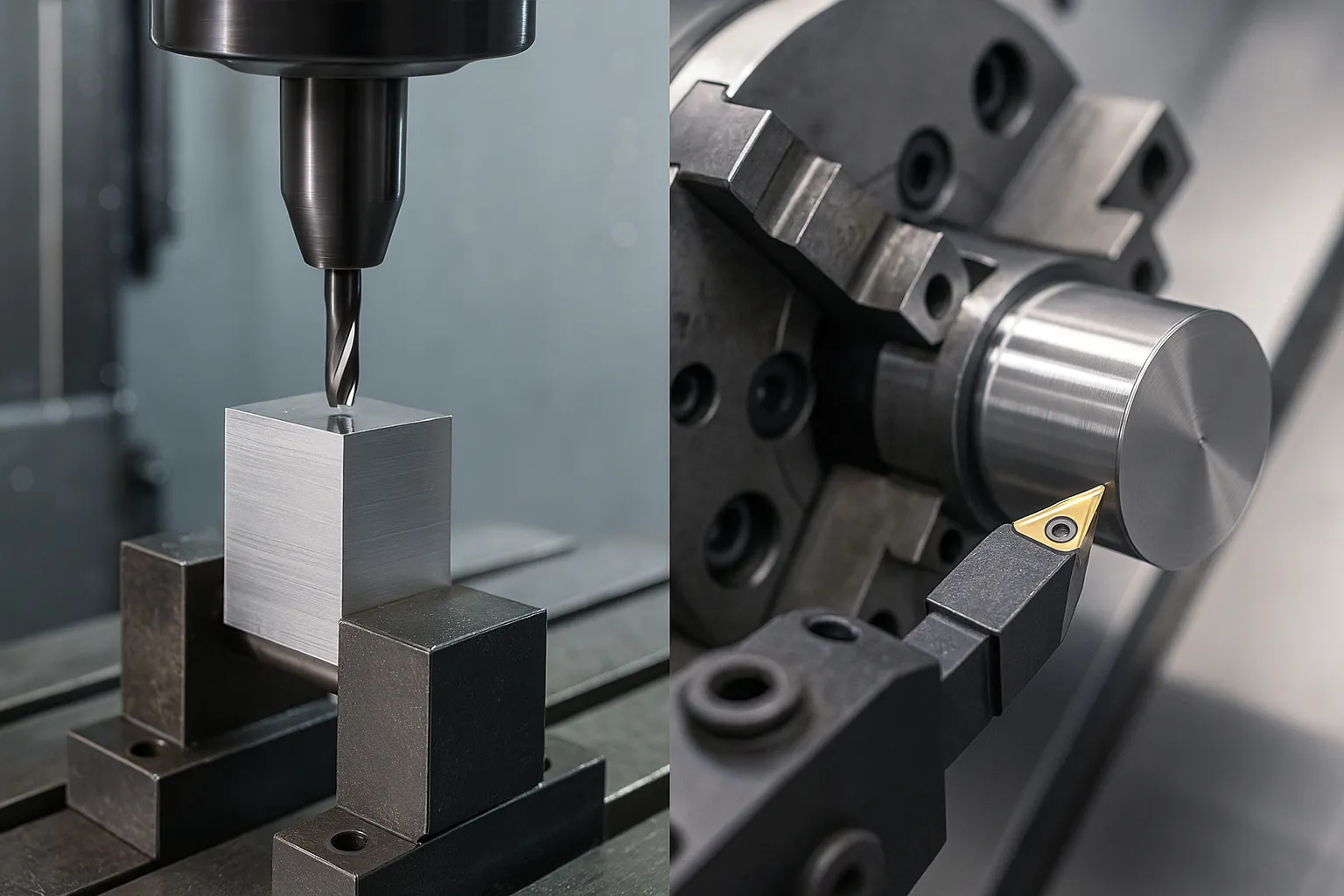

We provide high-precision Customized CNC Milling Solutions tailored to your specific project needs, from simple 3-axis parts to complex 5-axis geometries. Leverage our expertise to optimize quality, reduce production costs, and accelerate your time-to-market.

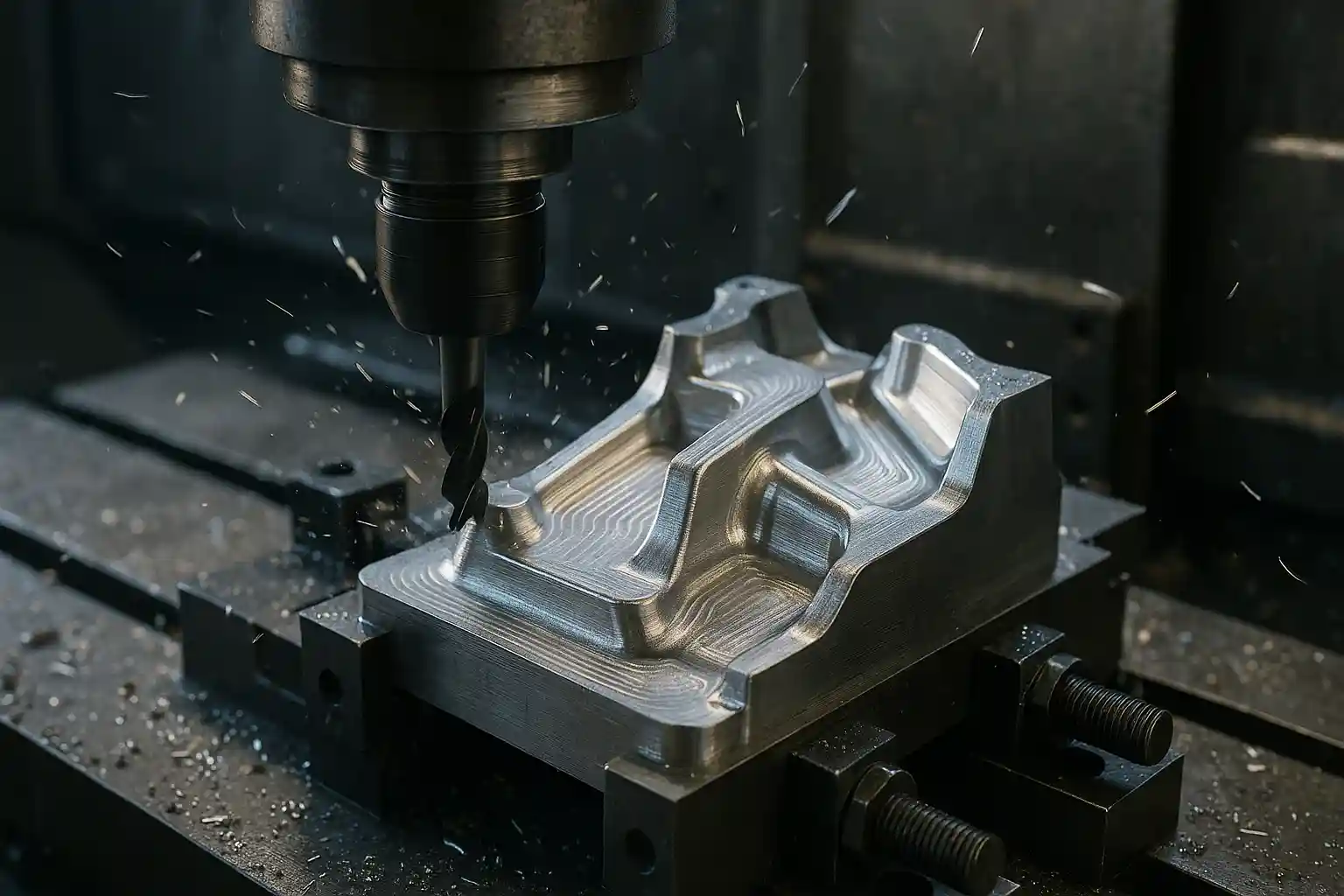

3-axis CNC milling

4-axis CNC milling

5-axis CNC milling

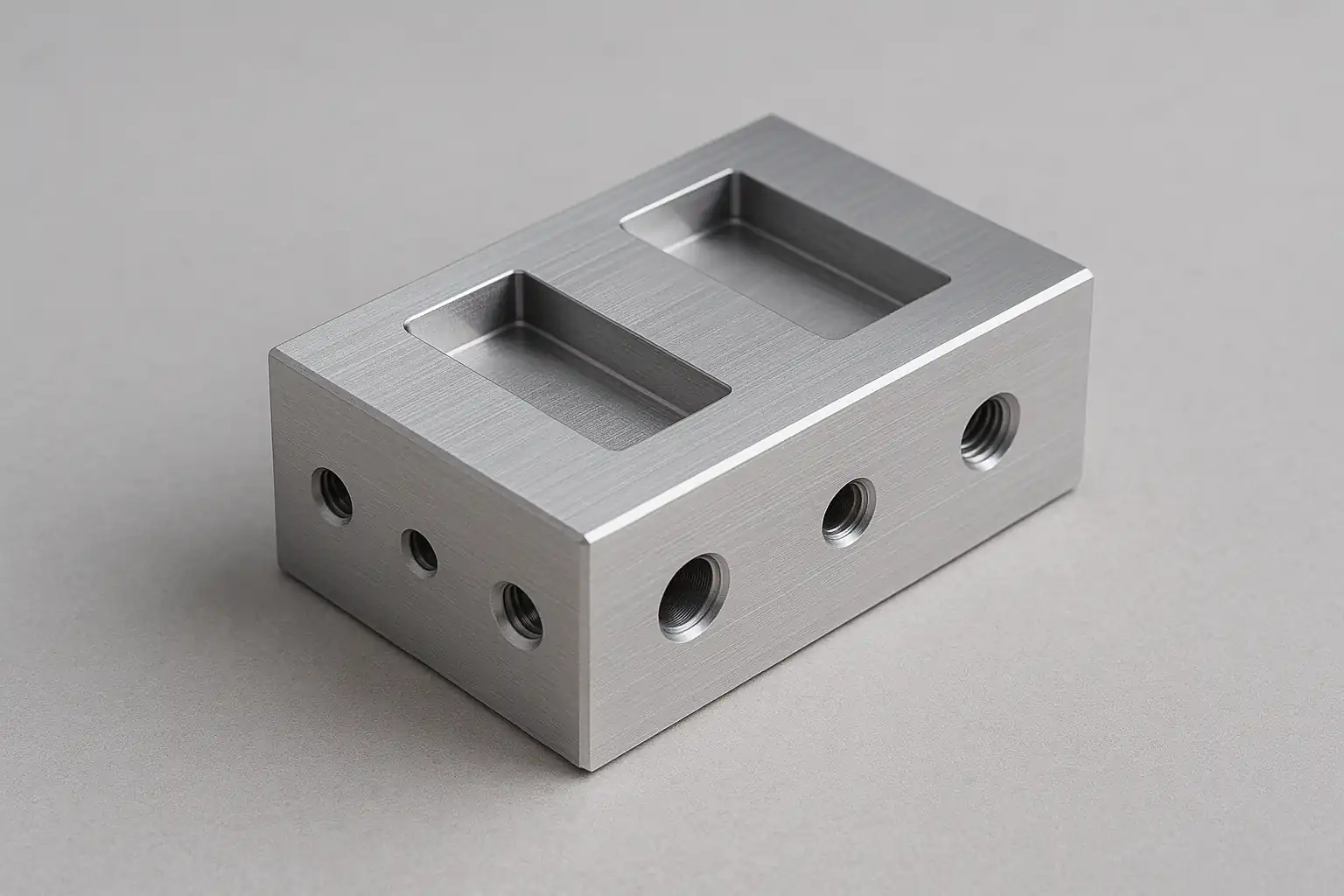

Material

| Material | Machinable Grades |

|---|---|

| Stainless Steel |

303 304 316L 410 17-4PH Duplex 2205 |

| Carbon/Alloy Steel |

1018 1045 4140 4340 Tool Steel (D2, A2) Mold Steel (P20) |

| Aluminum Alloy |

2024 5052 6061 6082 7050 7075 |

| Copper/Brass |

Brass (C36000) Bronze Beryllium Copper Red Copper (T2) |

| Engineering Plastics |

Acetal Nylon PEEK Teflon (PTFE) UHMW-PE PVC Polycarbonate ABS |

CNC General Tolerance

| Parameter | Value (Metric) | Value (Imperial) |

|---|---|---|

| Maximum Part Size | Diameter: Ø250 mm Length: 600 mm |

Diameter: Ø10 in Length: 24 in |

| Minimum Part Size | Diameter: Ø5 mm Length: 10 mm |

Diameter: Ø0.2 in Length: 0.4 in |

| Minimum Feature Size | Hole: Ø1 mm Wall: 1 mm |

Hole: Ø0.04 in Wall: 0.04 in |

| General Dimensional Tolerance | ±0.05 mm | ±0.002 in |

| Flatness Tolerance | 0.05 mm | 0.002 in |

| Perpendicularity Tolerance | 0.05 mm | 0.002 in |

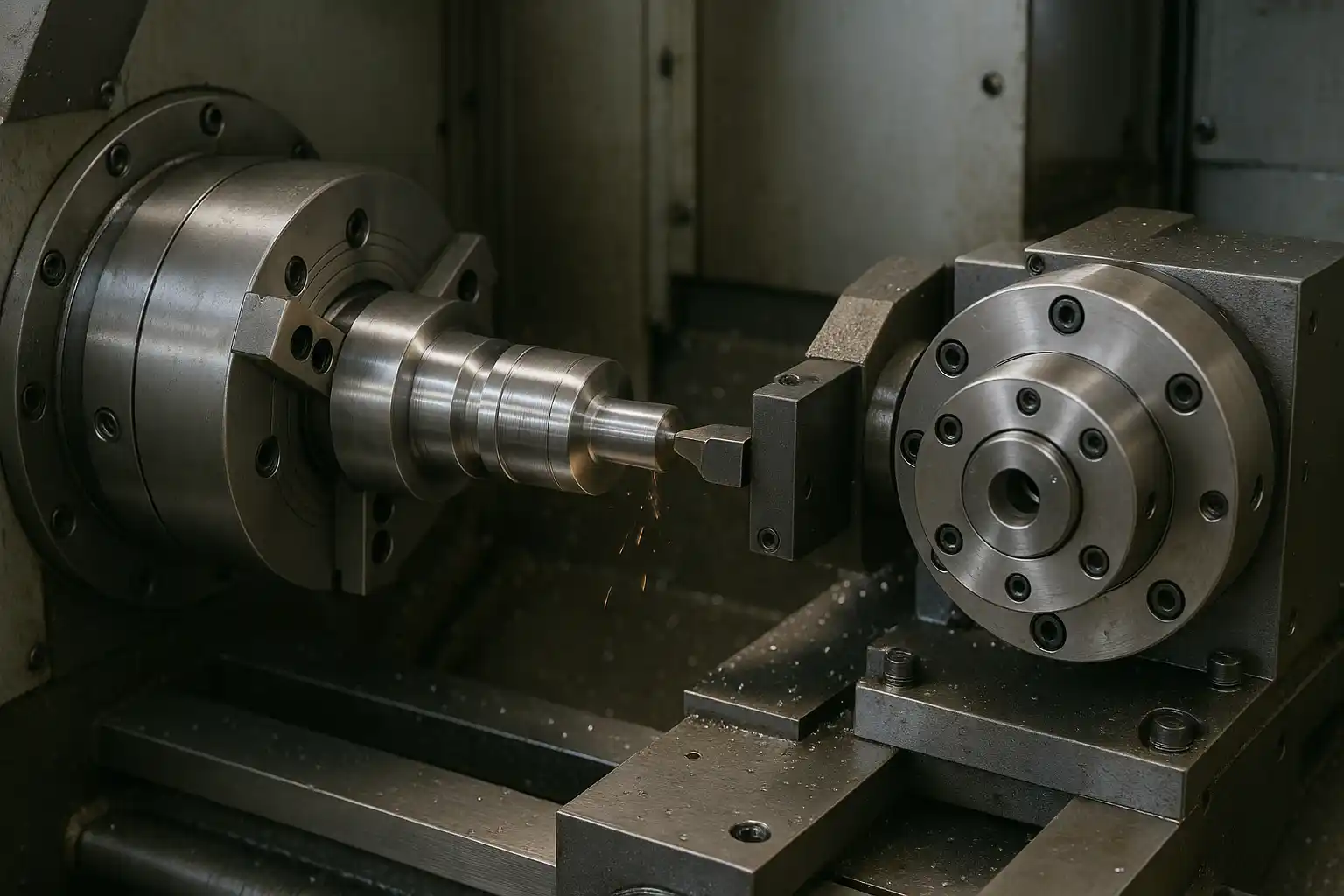

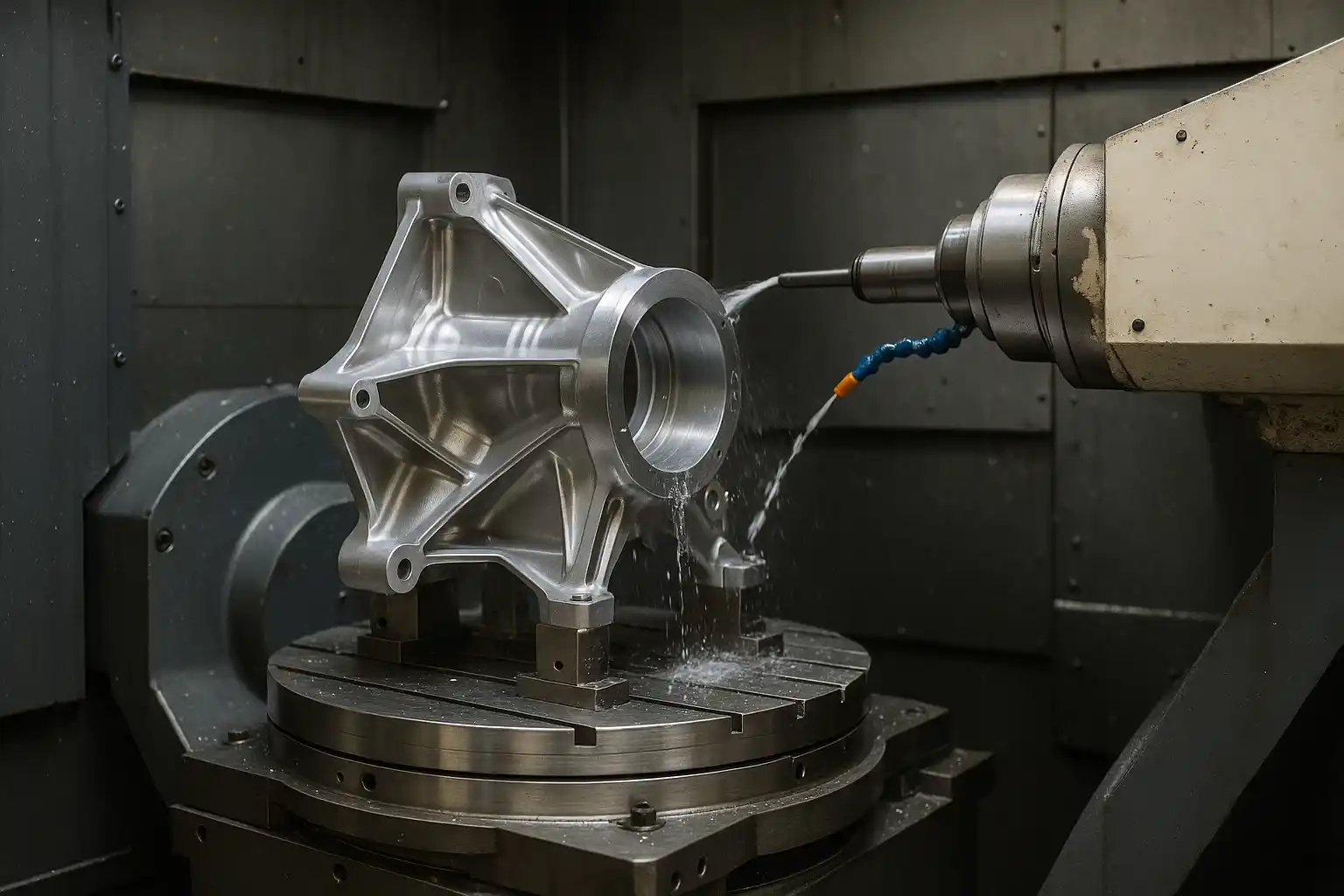

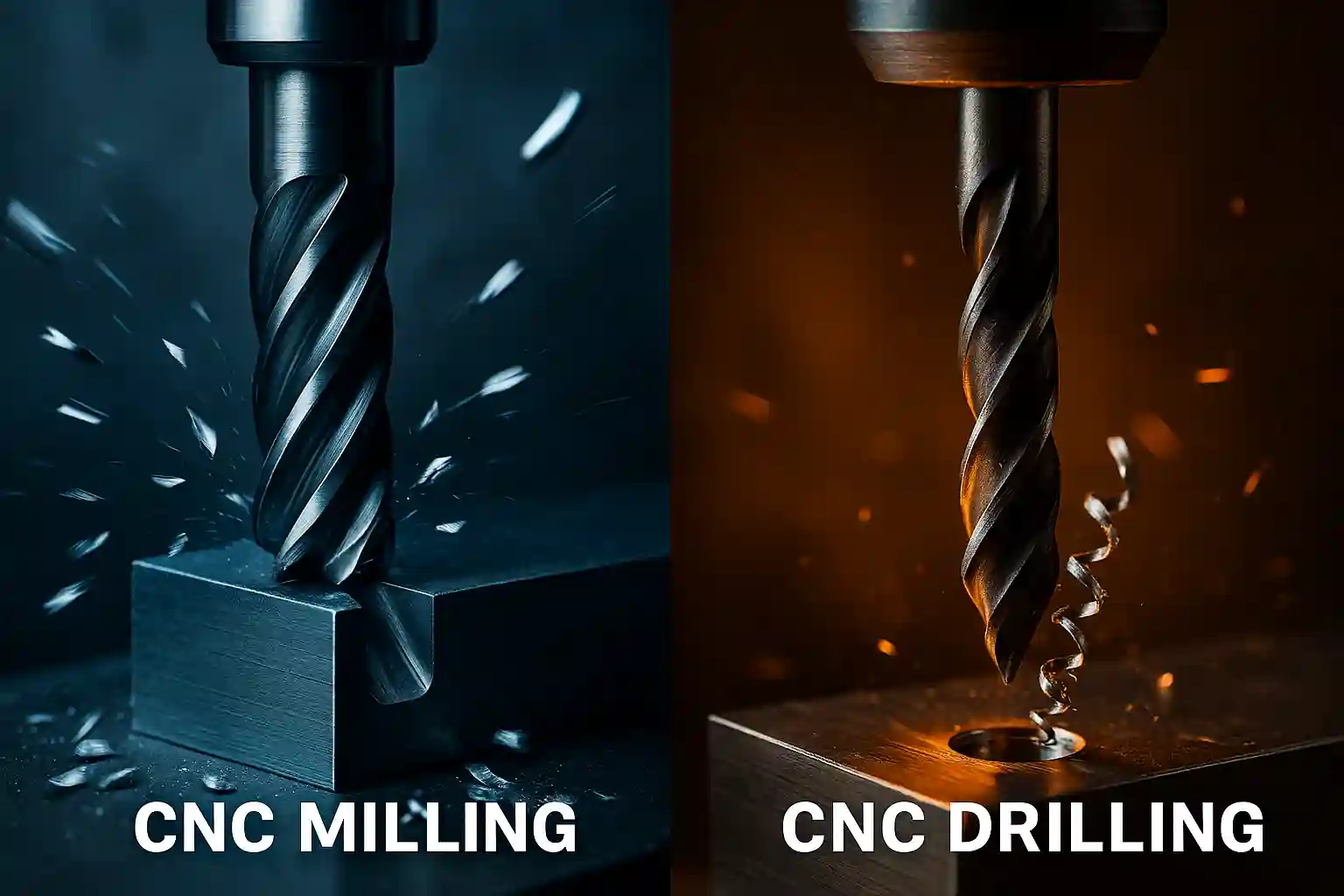

What is CNC Milling?

CNC milling is a precision machining process that uses rotating cutting tools to cut and remove material. Unlike CNC turning, where the workpiece rotates, in milling the part is typically held stationary. Controlled by a computer, the cutting tool can move along multiple axes to precisely carve out a wide variety of complex shapes, flat surfaces, grooves, and holes. This process is a cornerstone of manufacturing due to its extreme flexibility and is widely used to produce non-cylindrical parts and molds.