What services we provide

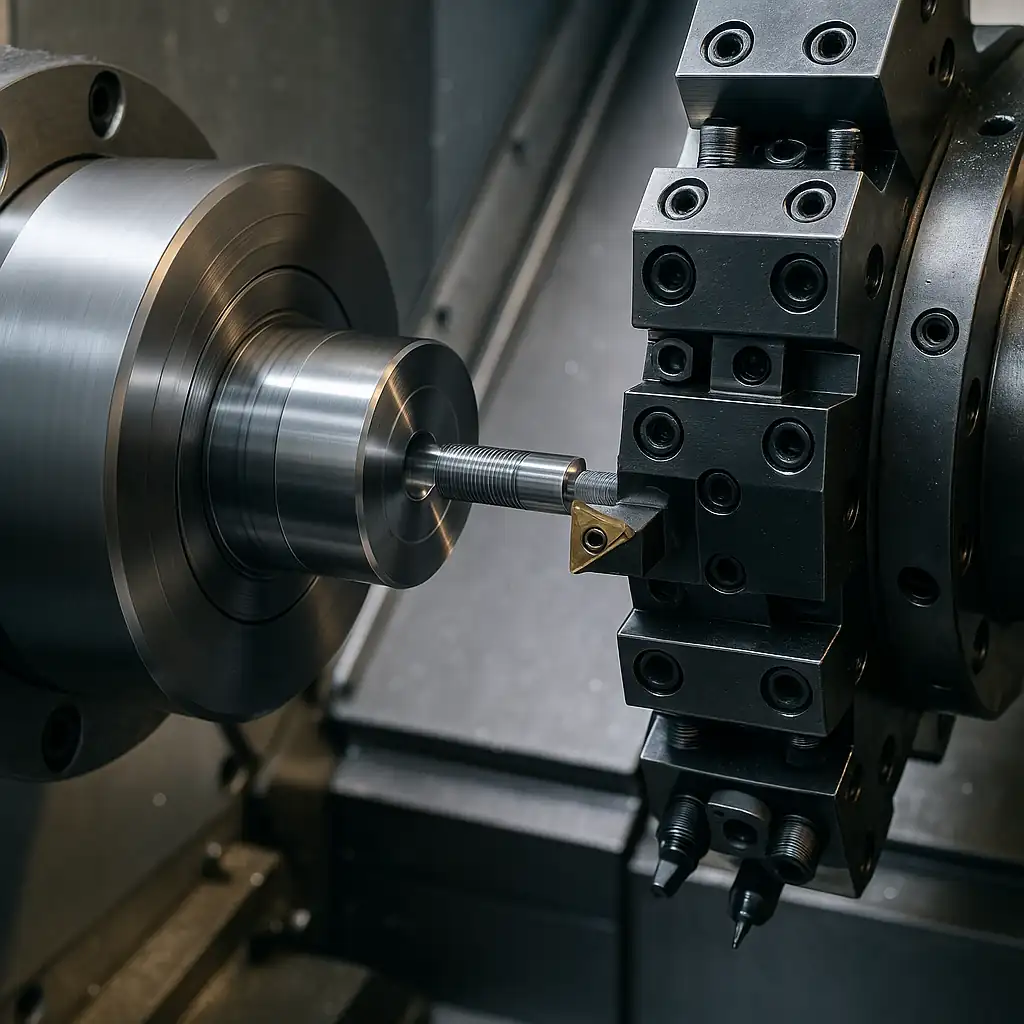

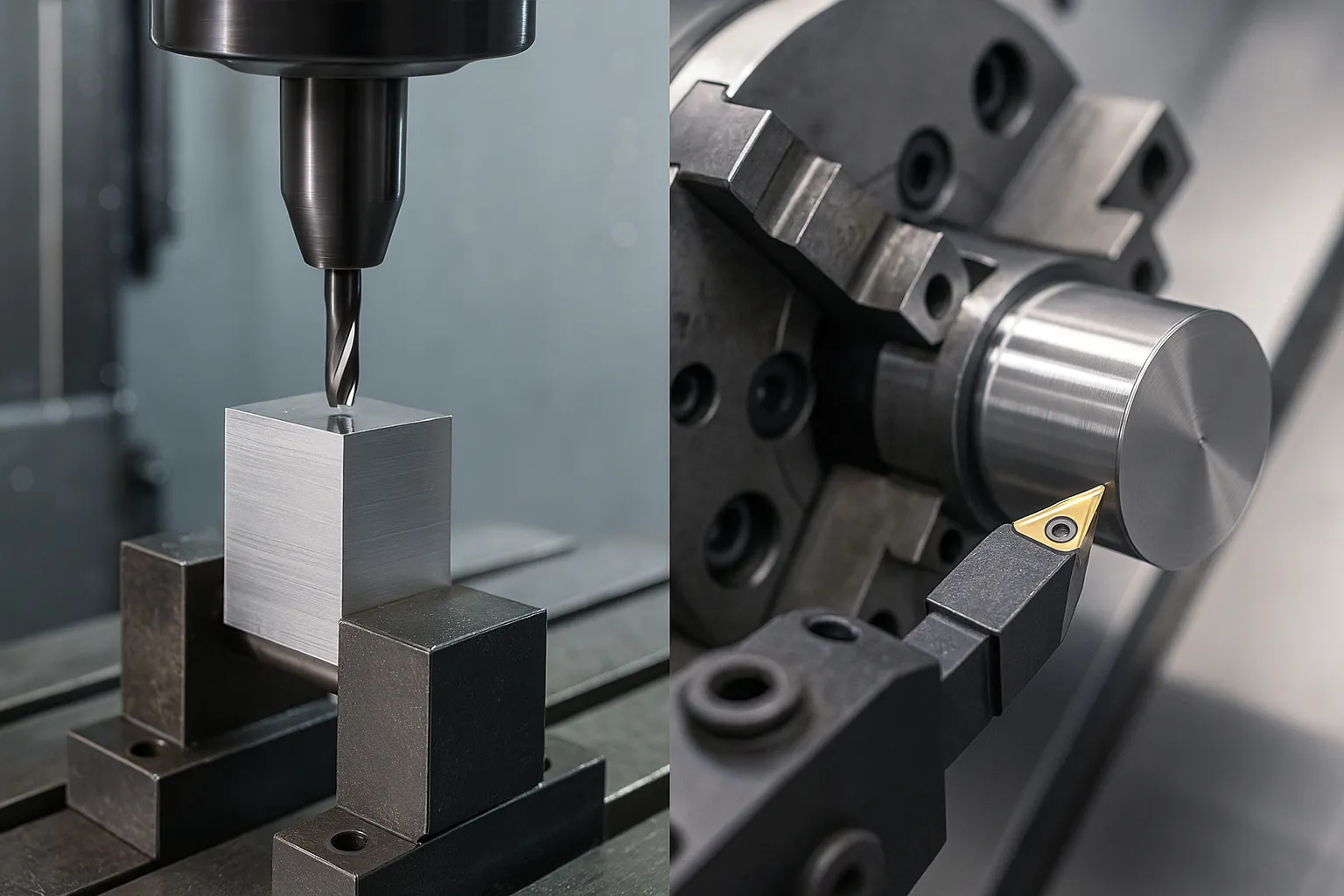

Precision CNC Turning

High-precision turning services with tolerances up to ±0.01mm. Specializing in complex cylindrical components, shafts, and precision parts for various industries.

Material Expertise

Extensive experience in machining various materials including stainless steel, aluminum, titanium, brass, and exotic alloys. Professional heat treatment services available.

Quality Assurance

Comprehensive quality control with advanced CMM inspection equipment, ensuring all parts meet exact specifications and international standards.

Production Capacity

From prototype to high-volume production, we offer flexible manufacturing solutions with quick turnaround times. Efficient batch processing available.

Industry Applications

Serving aerospace, medical, automotive, and industrial sectors with precision-turned components. Custom solutions for specialized requirements.

Material

| Material | Machinable Grades |

|---|---|

| Stainless Steel |

303 304 316L 310S 410 440C 17-4PH Duplex 2205 |

| Carbon/Alloy Steel |

1018 1045 A36 4140 4340 8620 |

| Aluminum Alloy |

2024 5052 6061 6082 7050 7075 |

| Copper/Brass |

Brass (C36000) Bronze (C932) Beryllium Copper Red Copper (T2) |

| Engineering Plastics |

Acetal Nylon PEEK Teflon (PTFE) UHMW-PE PVC Polycarbonate ABS |

CNC General Tolerance

| Parameter | Value (Metric) | Value (Imperial) |

|---|---|---|

| Maximum Part Size | Diameter: Ø250 mm Length: 600 mm |

Diameter: Ø10 in Length: 24 in |

| Minimum Part Size | Diameter: Ø5 mm Length: 10 mm |

Diameter: Ø0.2 in Length: 0.4 in |

| Minimum Feature Size | Hole: Ø1 mm Wall: 1 mm |

Hole: Ø0.04 in Wall: 0.04 in |

| Standard Tolerance | ±0.05 mm | ±0.002 in |

What is CNC Turning?

CNC turning is a precision machining process that creates cylindrical parts by rotating a workpiece at high speed while a stationary cutting tool removes material. Unlike CNC milling, where the tool rotates, in turning the part itself spins. This method is ideal for producing round, conical, and threaded components with exceptional accuracy and a smooth surface finish. Our advanced equipment can handle a wide range of materials and complex designs, ensuring your parts are made to the highest standards.