Titanium alloys are critical materials in aerospace, medical, and high-performance automotive industries due to their exceptional strength-to-weight ratio and corrosion resistance. Successfully machining these materials, however, presents distinct and formidable engineering challenges that require specialized tooling and optimized CNC strategies. This article details the core issues in titanium machining and outlines practical strategies for achieving efficiency and precision.

What Is Titanium Machining

Titanium machining involves subtractive manufacturing processes — such as milling, turning, and drilling — applied to pure titanium or its alloys. These processes are necessary to create high-precision components for demanding applications where material properties are paramount.

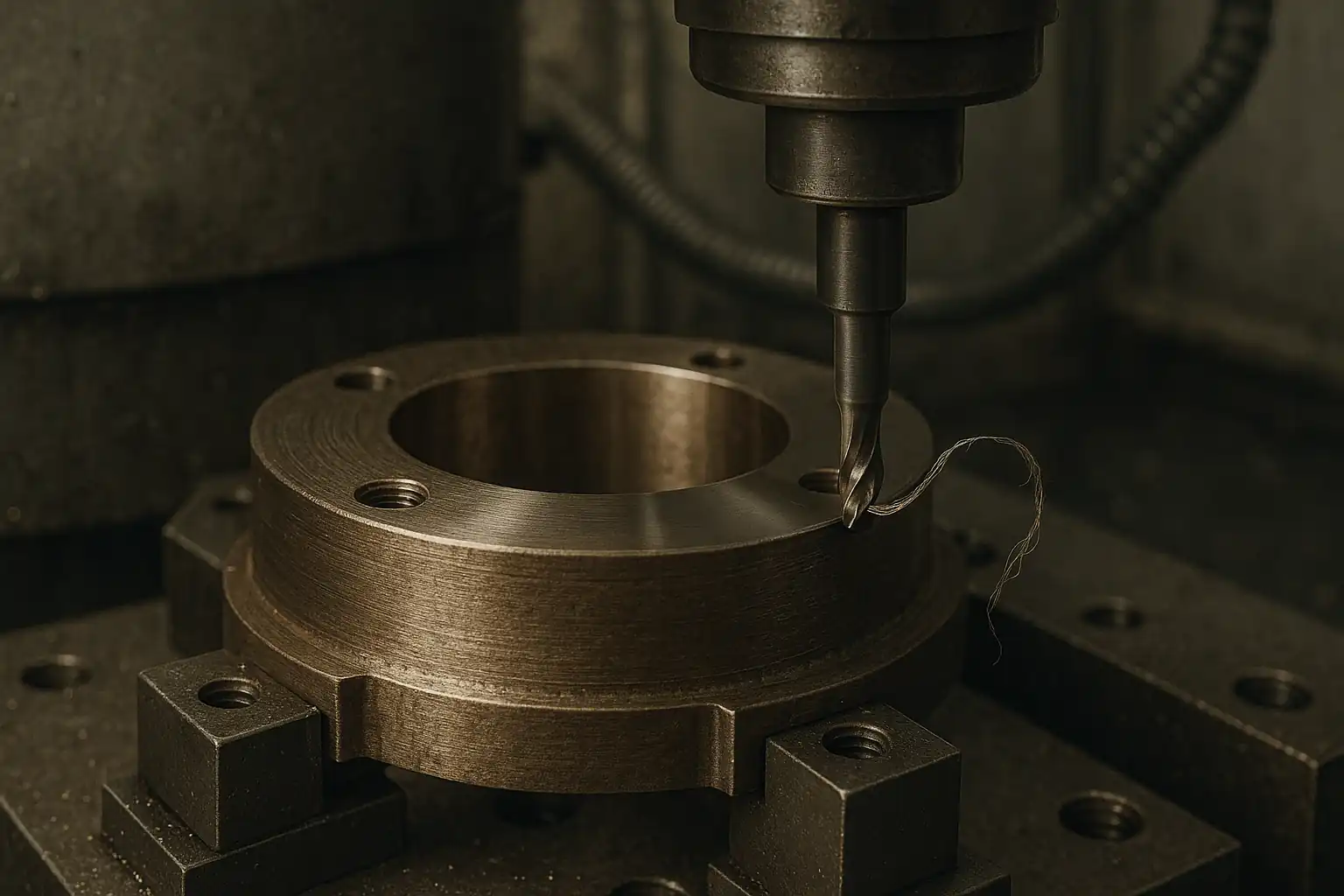

A close-up view of a precision-milled titanium alloy component highlighting smooth machining marks and tight tolerance finishing.

- The primary goal is to shape the material to final specifications, often involving complex geometries and tight tolerances (e.g., ± 0.015 mm).

- Machining must preserve the integrity of the material, avoiding defects like surface cracks, alpha case (a hard, brittle layer), and excessive residual stress.

- Alloys like Ti-6Al-4V (Grade 5, an α + β alloy) and Ti-5Al-2.5Sn (an α alloy) are the most common variants processed, each exhibiting slightly different machining characteristics.

- Due to the high cost of titanium material and the components’ criticality, process reliability and minimal scrap rates are non-negotiable requirements.

Machining Strategy for Titanium Alloys

| Machining Challenge | Impact on Machining | Optimization Strategy | Engineering Rationale |

|---|---|---|---|

| Low Thermal Conductivity (Heat Concentration) | Rapid thermal softening and wear on the tool tip due to heat accumulation at the tool–chip interface. | Low Cutting Speeds (vₙ) and Effective Cooling/Lubrication. | Reduces the rate of heat generation, maintaining tool–chip temperature below critical limits (≈ 500 °C) to extend tool life. |

| Chemical Reactivity (Adhesion / Diffusion) | Catastrophic tool failure, built-up edge (BUE), and poor surface finish. | Low Cutting Speeds (vₙ) and Coolant with High Lubricity. | Prevents cutting temperature from exceeding the activation threshold (> 500 °C) where titanium reacts strongly with tool materials such as WC or Co. |

| High Strength at Elevated Temperatures | High cutting forces and increased spindle load. | High Feed Rates (f) and Sharp Cutting Tools. | Larger chip thickness shifts heat away from the tool and minimizes frictional contact; sharp edges lower force and reduce rubbing. |

| Elasticity and “Spring-Back” | Flank wear and poor dimensional accuracy. | High Feed Rates (f) and Positive Rake Angle Tools. | Thicker chips and positive rake geometry reduce elastic recovery and rubbing, improving tolerance control (± 0.01 mm). |

| Segmented (Serrated) Chip Formation | Cyclic cutting forces and micro-chipping of tool edge. | Rigid Machine Setup, Stable Fixturing, and Controlled Cutting Speed. | Minimizes vibration and mechanical shock caused by periodic chip segmentation, enhancing surface integrity. |

Challenges in Titanium Machining

The physical and chemical properties of titanium translate directly into specific, persistent challenges on the shop floor. These issues directly impact production costs, cycle times, and the quality of the final component.

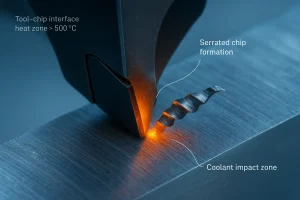

Close-up visualization of titanium chip segmentation during cutting, highlighting the tool–chip interface and thermal effects typical in Ti-6Al-4V machining.

- Rapid Tool Wear and Catastrophic Failure: Heat concentration and chemical wear mechanisms combine to cause extremely fast and unpredictable wear on the cutting tools. Tool life can be only a few minutes, mandating frequent and costly tool changes.

- Low wear resistance increases tool cost per part and requires frequent process interruption for tool inspection.

- Unpredictable failure can result in immediate component scrap, which is costly given the price of titanium stock.

- Maintaining Surface Integrity and Preventing Contamination: The severe thermal and mechanical stresses can damage the surface layer of the machined part.

- Excessive heat causes localized phase transformation and can create the hard, brittle alpha case on the surface, which compromises fatigue life and requires subsequent removal.

- Achieving the required surface finish (often Ra 0.8 µm to 1.6 µm) is difficult due to BUE and flank wear.

- Chip Management: The chips generated are hot, sharp, and tend to weld to themselves, the tool, or the workpiece.

- Poor chip evacuation causes re-cutting, heat build-up, and tool breakage.

- Chips can also damage the finished surfaces of the part or contaminate the coolant system.

- High Cutting Forces and Vibration: High material strength requires large forces, increasing the risk of deflection, chatter (self-excited vibration), and reduced machine tool and fixture life.

- Rigid fixturing and high-dynamic stiffness machine tools are mandatory to minimize relative movement between the tool and the workpiece.

- Thermal Deformation: During heavy milling, localized heat and low stiffness may cause minor distortion in thin-walled titanium parts. Maintaining stable temperature and rigid fixturing minimizes this risk.

Cutting Tools for Titanium

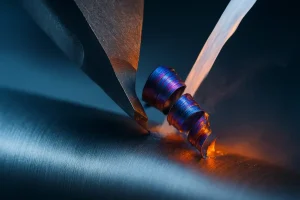

Close-up image of titanium turning showing segmented blue chips and coolant application near the cutting zone.

Selecting the correct cutting tool material, geometry, and coating is the single most critical factor for successful and efficient titanium machining. Tooling choices must address the high heat and chemical reactivity of the process.

- Carbide Grades: Uncoated fine-grain tungsten carbide (WC) is the primary material choice. Specific grades with high cobalt content (around 10% to 12%) provide toughness and resistance to the mechanical shock and thermal fatigue common in titanium.

- The carbide must possess high hot hardness and transverse rupture strength.

- PVD-applied coatings, such as TiAlN (Titanium Aluminum Nitride) or AlTiN, can improve performance by acting as a thermal barrier, but they must be thinly applied to maintain edge sharpness.

- Geometry and Rake Angle: Tool geometry is designed to manage heat and shear the material efficiently without generating excessive friction.

- Use positive rake angles to reduce cutting forces and direct heat into the chip. A positive geometry promotes clean cutting and minimizes flank rubbing.

- Sharp cutting edges are essential, necessitating a controlled, small-radius T-land or honing to balance sharpness with edge strength.

- Large chip-breaker grooves are generally avoided; instead, open, polished geometries are preferred for efficient chip flow.

- Insert Style and Tool Holders: Indexable inserts should be selected for high strength and secure seating.

- Round inserts or tools with large lead angles (e.g., 45°) are highly effective in milling as they thin the chip and direct forces axially into the spindle, prolonging tool life.

- Tool holders must provide maximum rigidity, often using shrink-fit or high-clamping-force hydraulic chucks to eliminate runout and dampen vibration.

- Advanced Tooling: For roughing and high-volume applications, specialized materials offer advantages.

- Ceramic inserts (especially silicon nitride or whisker-reinforced ceramics) can operate at significantly higher cutting speeds (Vc 150 m/min to 300 m/min) in roughing, but they are extremely brittle and require very stable machining conditions and machines.

- Polycrystalline Diamond (PCD) is highly effective for pure, unalloyed titanium but is generally not suitable for abrasive titanium alloys like Ti-6Al-4V due to chemical wear.

Recommended Tooling Setup

- Use PVD-coated fine-grain carbide (TiAlN / AlTiN) for general machining of α + β alloys.

- Si₃N₄ ceramic inserts for high-speed finishing if the setup is highly rigid.

- PCD tools for pure titanium or composite parts requiring ultra-fine surface finishes.

- Combine with hydraulic or shrink-fit holders and through-coolant (70 bar – 100 bar) for optimal stability.

CNC Machining Process for Titanium

Yes, titanium alloys can be CNC machined effectively — provided that speed, feed, coolant delivery, and machine rigidity are precisely controlled. Successful CNC machining of titanium relies on a strategy of low-speed, high-feed, and aggressive, consistent application of High-Pressure Coolant (HPC). Process parameters must prioritize thermal control over maximum material removal rate (MRR).

Cooling and Lubrication Strategy

- High-Pressure Coolant (HPC): Applying coolant at high pressure (70 bar – 100 bar) is mandatory to blast the chip away from the cutting zone and remove concentrated heat.

- HPC also aids in chip breaking and prevents re-cutting.

- Soluble oil (emulsion) is the preferred coolant type, providing superior lubrication and heat transfer compared to synthetic oils.

- Through-Tool Coolant: Delivering the coolant directly through channels in the tool holder and cutting tool ensures precise application at the point of action (the cutting edge).

Cutting Parameters Optimization

- Low Cutting Speed (Vc): The most critical parameter is the cutting speed. Low thermal conductivity traps heat, so a low Vc is essential to prevent rapid thermal wear and 750 °C flash temperatures.

- Recommended range for roughing Ti-6Al-4V with carbide is typically Vc 40–60 m/min.

- High Feed Rate (fz): Use a relatively high chip load (feed per tooth, fz) to ensure that heat is consistently carried away with a thick chip, minimizing thermal exposure of the tool flank.

- The chip thickness must exceed the nose radius or cutting edge preparation to shear cleanly.

- Depth of Cut (ap): Maintain a consistent, deep radial (ae) or axial (ap) depth of cut that is greater than the flank wear land. This ensures the tool is cutting in a clean, fresh zone rather than rubbing a hardened area.

- Trochoidal Milling and high-efficiency milling (HEM) techniques are effective in milling, using a full ap and a low ae to maintain a constant, low radial chip engagement, reducing thermal fluctuations.

Machine Tool and Setup Requirements

- Machine Rigidity: Use high-power, high-stiffness CNC machines with heavy construction (e.g., box ways) and robust spindles. The machine must be able to absorb the high, intermittent cutting forces without deflecting.

- Fixturing: Over-engineered fixturing is necessary to dampen vibration and prevent workpiece movement. Use minimal tool overhang to maximize system rigidity and push the chatter frequency above the operational range.

- Monitoring and Adaptive Control: Implement systems for real-time tool wear monitoring (e.g., acoustic emission or force sensors) and adaptive control to automatically adjust feed rates based on spindle load, ensuring tool life consistency and protection against sudden failure.

- Milling Strategy (Climb vs. Conventional): Climb milling is strongly preferred, as it ensures the tool enters the material at maximum chip thickness and shears downward, reducing the rubbing effect and minimizing the risk of BUE.

Common Questions About Titanium Machining

The following quick answers address some of the most common questions manufacturing teams have about machining titanium alloys.

Is titanium difficult to machine?

Yes – its low thermal conductivity and high strength lead to heat accumulation and rapid tool wear, making it challenging to cut efficiently.

Can titanium be CNC machined?

Absolutely. With rigid machines, TiAlN-coated carbide tools, and High-Pressure Coolant (70 bar – 100 bar), precision CNC machining achieves excellent accuracy and surface finish.

What tools work best for cutting titanium?

Fine-grain carbide (TiAlN / AlTiN) is most common; ceramics or PCD are used for specialized grades.

Why is titanium machining expensive?

Tool life is short and cutting speed low, but the strength-to-weight and corrosion resistance make titanium cost-effective for aerospace and medical applications.

Conclusion

Machining titanium alloys is a complex, high-stakes engineering endeavor where success is defined by meticulous process control, specialized tooling, and a profound understanding of the material’s thermal and chemical behaviors. By adhering to the principles of low cutting speed, high feed, aggressive High-Pressure Coolant, and using tough, positive-geometry carbide tooling, manufacturers can mitigate the core challenges of rapid wear and high heat. The resulting optimized CNC strategies transform a demanding process into a reliable, efficient operation capable of producing the high-integrity components required by critical industries. Process expertise is paramount in maximizing material removal rates while guaranteeing component quality and tool life. While titanium machining involves higher tooling and material costs than steel or aluminum, its superior performance justifies the investment for critical components.