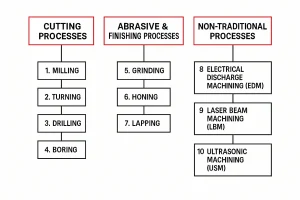

In the complex field of manufacturing, achieving component precision relies on selecting the right process. This guide covers the three main types of machining processes (Cutting, Abrasive & Finishing, and Non-Traditional), detailing ten core techniques that engineers use to shape materials.

Cutting Processes

Cutting processes form the largest part of machining, relying on sharp cutting tools to apply mechanical force and rapidly remove material. These methods, including milling, turning, drilling, and boring, are essential for creating the basic geometry of a part and achieving high-volume, efficient shaping.

1. Milling

Milling is one of the most versatile and flexible processes. It uses a multi-toothed, rotating cutter while the workpiece or cutter moves along multiple axes (3-axis or 5-axis) to precisely shape the part. This method is capable of handling complex geometries, making it a primary choice for everything from mold making to aerospace component production.

- Key Feature: High multi-axis capability, suitable for complex geometries like planes, contours, slots, and cavities.

- Main Applications: Manufacturing molds, complex mechanical brackets, and aerospace components.

- Work Steps:

- Part Clamping: Securely fix the workpiece to the table to ensure rigidity.

- Path Programming: Define the tool trajectory and set cutting parameters (feeds and speeds).

- High-Speed Cutting: The cutter rotates at high speed, removing material through multi-axis movements.

- Chip Management: Continuously clear chips and use coolant to control thermal expansion.

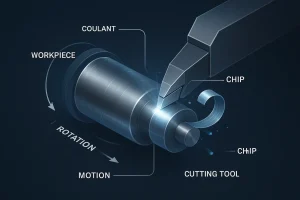

2. Turning

Turning is a foundational cutting process used to create parts with rotational symmetry. The workpiece is rotated at high speed while a single-point cutting tool moves along the axis or radially to remove material from the external or internal surfaces of the part.

- Key Feature: Efficient processing of parts of revolution, primarily creating external and internal cylindrical features.

- Main Applications: Manufacturing shafts, threads, pins, and discs.

- Work Steps:

- Workpiece Mounting: Secure the circular workpiece in the chuck for high-speed rotation.

- Tool Setting & Feed: The fixed tool moves radially or axially, with feed rate precisely set.

- Rough/Finish Machining: Perform high-material-removal rough cuts, followed by precise finishing cuts.

- Parting: Once the part is formed, it is cut away from the raw material stock.

3. Drilling

Drilling is an efficient hole-making method designed to create or enlarge cylindrical holes. It uses a drill bit that rotates and feeds axially into the workpiece, typically used to provide locations for subsequent assembly.

- Key Feature: High efficiency for creating through-holes or mounting holes; relatively singular function.

- Main Applications: Creating mounting holes for screws, pins, or passages.

- Work Steps:

- Centering: Use a center drill to precisely locate the hole’s entry point. . Drill Feed: The main drill rotates and feeds axially into the workpiece.

- Peck Drilling: For deep holes, use intermittent withdrawal (peck drilling) for effective chip evacuation and cooling.

- Hole Verification: Measure hole diameter and location for accuracy.

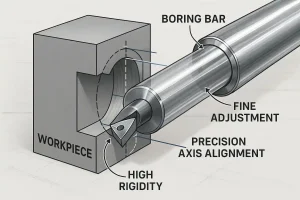

4. Boring

Boring is a finishing process aimed at enlarging, refining, and correcting the size, roundness, or concentricity of an existing hole. It uses a single- or multi-point boring bar to achieve the final, high-precision geometric requirements of a hole.

- Key Feature: High precision, primarily used to correct the geometric accuracy, coaxiality, and surface roughness of a hole to meet strict tolerances.

- Main Applications: Finishing engine cylinder bores and bearing seats.

- Work Steps:

- Roughing Allowance: Ensure the hole has been roughed and a small finishing allowance remains.

- Boring Bar Adjustment: Precisely set the boring bar diameter to micron-level tolerance.

- Low-Feed Finishing: The rigid boring bar performs a fine cut along the hole wall at a low feed rate.

- Dimension Validation: Verify the final hole size and shape using precision gauges (e.g., air gauges).

Abrasive & Finishing Processes

Abrasive and finishing processes remove material in extremely small increments through the action of abrasive particles. These methods typically follow initial cutting, aiming to maximize surface finish, dimensional accuracy, and geometric precision—they are key to meeting the tightest tolerance requirements.

5. Grinding

Grinding is a high-precision finishing method particularly suitable for hard materials. It uses a high-speed rotating grinding wheel made of abrasive particles to remove material through micro-cutting and friction, resulting in exceptionally high surface finish and dimensional accuracy.

- Key Feature: Suitable for extremely hard materials (e.g., hardened steel), achieving superior surface finish and dimensional accuracy.

- Main Applications: Finishing journals on shafts, precision tool edges, and bearing raceways.

- Work Steps:

- Wheel Selection & Balance: Choose the appropriate abrasive type, grit size, and bond for the material, and balance the wheel.

- Wheel Dressing: Periodically dress the wheel surface to expose new sharp abrasive particles.

- High-Speed Contact: The wheel rotates at high speed, contacting the workpiece with a minimal infeed to remove material.

- Constant Cooling: Use abundant coolant to control thermal damage and prevent burning or micro-cracks.

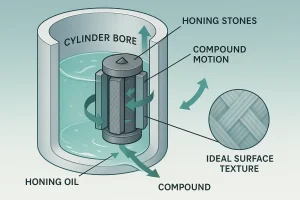

6. Honing

Honing is a super-finishing process primarily applied to the inner surface of holes. It uses a honing head and abrasive stones to perform a slow, reciprocating cut against the hole wall, improving roundness and surface texture by removing minute flaws.

- Key Feature: A form of super-finishing, primarily used to improve a hole’s roundness and surface texture.

- Main Applications: Finishing cylinder liners and hydraulic valve bores.

- Work Steps:

- Honing Head Setup: Insert the abrasive-stone-equipped honing head into the pre-machined hole.

- Pressure and Lubrication: The stones expand under controlled pressure while specialized honing oil is pumped in.

- Compound Motion: The honing head performs a slow rotational and axial reciprocating motion.

- Cross-Hatch Pattern: Precisely control the speed ratio to form an optimal cross-hatch pattern on the wall for lubrication retention.

7. Lapping

Lapping is another super-finishing process used to achieve extremely high surface flatness and finish. It utilizes a lapping tool (lap plate) and an abrasive slurry, removing microscopic amounts of material through free abrasion.

- Key Feature: Achieves extremely high surface flatness and finish, removing minimal material.

- Main Applications: Finishing optical surfaces, valve sealing faces, and gauge block surfaces.

- Work Steps:

- Slurry Preparation: Mix ultra-fine abrasive particles with liquid to form a lapping slurry.

- Slurry Application: Apply the lapping slurry uniformly onto the lap plate surface.

- Free Abrasion: The workpiece is moved randomly across the lap plate surface to ensure non-fixed, non-repeating relative motion.

- Final Cleaning: Thoroughly clean the workpiece to remove all residual abrasive particles.

Non-Traditional Processes

Special and non-traditional processes do not rely on conventional cutting forces. Instead, they use specialized physical effects such as electrical, light, or chemical energy to remove material. They are primarily used for machining ultra-hard or brittle materials, or for creating complex micro-structures that conventional methods cannot handle.

8. Electrical Discharge Machining (EDM)

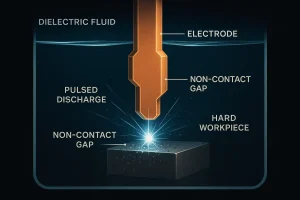

EDM is a non-contact process that removes material using electrical energy rather than mechanical force. It works on any electrically conductive material and is particularly adept at machining high-hardness materials and complex cavities.

- Key Feature: Non-contact process, works on all conductive materials, excels at machining high-hardness materials and deep, narrow cavities.

- Main Applications: Manufacturing precision molds and complex internal features.

- Work Steps:

- Electrode Fabrication: Create the required copper or graphite electrode to act as the tool.

- Dielectric Immersion: Immerse the workpiece and electrode in an insulating dielectric fluid.

- Pulsed Discharge: Apply high-frequency pulsed voltage between the electrode and the workpiece, creating sparks that melt or vaporize material.

- Flushing: The dielectric fluid constantly circulates to flush away the eroded material (slag) and cool the gap.

9. Laser Beam Machining (LBM)

LBM is a non-contact process that uses a high-energy beam of light to remove material. The focused beam uses thermal energy to melt and vaporize the workpiece, making it suitable for precise cutting and micro-hole drilling in various materials.

- Key Feature: Non-contact, small heat-affected zone, suitable for various materials, excels at cutting thin sheets and micro-hole drilling.

- Main Applications: Precision marking, thin sheet cutting, and drilling ultra-fine holes.

- Work Steps:

- Beam Focusing: The high-energy laser is focused to an extremely small spot size via an optical system.

- CNC Positioning: The computer controls the movement of the beam or the stage along the programmed path.

- Material Removal: The focused beam instantly vaporizes or melts the material.

- Assist Gas: An assist gas (like Nitrogen or Oxygen) is jetted to blow away molten material and ensure a clean cut.

10. Ultrasonic Machining (USM)

USM is a unique non-traditional process primarily used for brittle materials. It uses a tool head vibrating at ultrasonic frequency to drive an abrasive slurry, which impacts the workpiece at high speed to remove material.

- Key Feature: Suitable for brittle materials like glass, ceramics, and cemented carbides.

- Main Applications: Creating micro-structures and drilling non-circular holes in brittle materials.

- Work Steps:

- Tool Head Setup: Mount the tool head, which matches the required feature shape, onto the transducer.

- Slurry Pumping: Pump the abrasive slurry into the gap between the tool head and the workpiece.

- Ultrasonic Vibration: The tool head vibrates at ultrasonic frequency (typically 15-30 kHz).

- Abrasive Impact: The vibrating tool drives abrasive particles to impact the workpiece surface, achieving material removal at a microscopic level.

Key Differences Between the Three Process Categories

After reviewing the unique principles and applications of each of the ten techniques, it’s essential to understand how the three major categories—Cutting, Abrasive, and Non-Traditional—compare. Understanding these fundamental differences is crucial for engineers and designers to make the correct trade-offs between cost, speed, and precision during the initial design phase. The table below summarizes their core distinctions.

| Category | Core Principle | Typical Machining Speed | Precision & Surface Finish | Applicable Material Range |

| Cutting (Mill, Turn, Drill, Bore) | Mechanical Shearing (using sharp tools) | High (Suitable for rapid, bulk material removal) | Medium to High (Used for roughing and moderate tolerance requirements) | Most metals, alloys, and plastics |

| Abrasive & Finishing (Grind, Hone, Lap) | Micro-Abrasive Cutting/Friction (using bonded or loose grit) | Low (Minimal material removal, time-consuming) | Extremely High (Used for the highest tolerances and surface roughness grades) | Extremely hard materials (e.g., hardened steel, carbides) |

| Non-Traditional (EDM, LBM, USM) | Energy Removal (Electrical, Optical, Mechanical Oscillation) | Medium to High (Varies by process and material) | Medium to High (Can machine complex shapes; finish may require additional work) | Ultra-hard, high-melting-point, conductive, or brittle materials |

Conclusion

Modern machining is a precise system composed of diverse processes. From cutting for rapid shaping, to abrasive finishing for ultra-high precision, and non-traditional methods for challenging materials and micro-structures, each technique holds irreplaceable value. Understanding the principles and work steps is key to optimizing design, controlling costs, and guaranteeing final product performance. Choosing the right combination of processes allows for maximizing efficiency while meeting all design specifications.

Seek Manufacturing Partnership and Technical Optimization

Your projects require balancing technical challenges with commercial efficiency. If you are evaluating the feasibility of a complex part or need to optimize existing designs to reduce manufacturing costs, please contact our technical consulting team. We will leverage our deep expertise to provide you with the most suitable process planning and customized manufacturing solutions.