As the demand for manufacturing sophistication rises, 5-axis simultaneous contouring stands out as a key capability of 5-axis CNC machines. This advanced machining method allows manufacturers to achieve a new level of efficiency by machining complex parts complete in a single setup, as opposed to conventional 3+2 or 4+1 milling operations. This facet of CNC contouring produces complicated and extremely accurate parts with multi-plane machining, making it essential for industries like automotive, aerospace, and medical. To understand the foundational principles of this technology, we invite you to explore our comprehensive 5-axis machining guide.

What is Simultaneous Contouring?

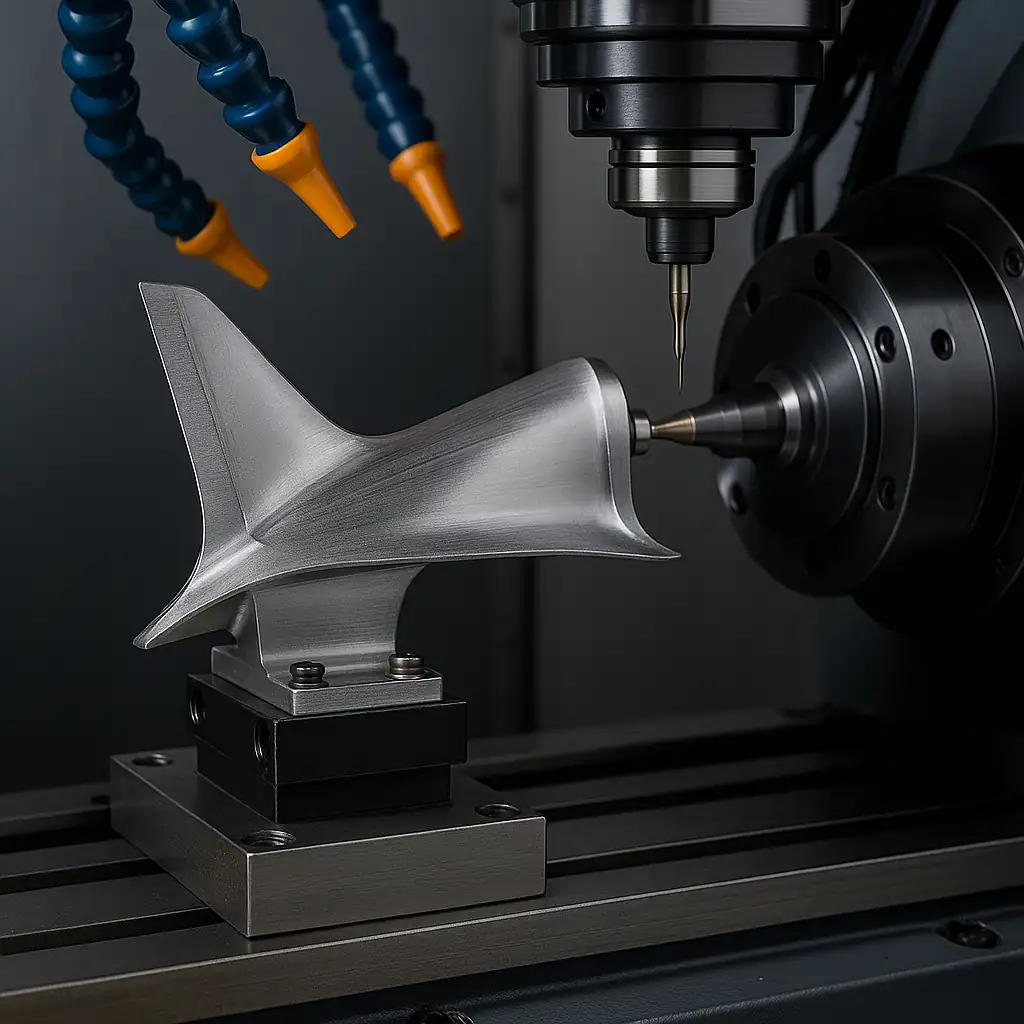

Simultaneous contouring, or 5-axis contouring, is an advanced process for seamless and continuous cutting of complex, contoured surfaces. This machining process differs from conventional production methods, such as 3-axis machining, because true 5-axis machines allow rotational axes (A, B, or C-axis) to move at the same time as the X, Y, and Z-axis during production.

5-Axis vs. 3-Axis Capabilities

In 3-axis equipment, machining only happens on three linear axes (X, Y, and Z). While it’s a robust solution for many applications, its capabilities do not extend to creating intricate geometries or complex curves with high precision.

Now, imagine the 3-axis machining process, but with more spatial freedom. That’s the unique advantage of 5-axis machining. By adding two rotational axes (A and B or C) to the existing X, Y, and Z linear axes, 5-axis machines can simultaneously approach the workpiece from all five sides.

How Manufacturers Benefit

The benefits of 5-axis simultaneous contouring lie not in its complexity, but rather in how it simplifies the production of complex parts, enhances efficiency, and drives innovation in precision manufacturing. The added complexity of 5-axis simultaneous contouring does not merely translate to more intricate designs, but also superior surface finishes and reduced machining times.

Imagine a complex, curving part, like a turbine blade. To machine this using a 3-axis system would require multiple setups and repositioning, whereas a 5-axis machine can accomplish it in a single setup, maintaining a continuous and efficient tool path.

Advantages of 5-Axis Simultaneous Contouring

1. Increased Accuracy and Precision

The additional rotational axes in 5-axis contouring provide enhanced machining accuracy and precision. Machines with this capability keep the spindle, workpiece, and tool in the correct position. This reduces errors while producing parts that are at or below the required print tolerances.

2. Reduced Cost and Time

The ability of 5-axis machines to keep the tool in the cut for any type of material with one setup significantly reduces machining time. The efficiency of multi-plane machining lowers labor costs, minimizes errors, and results in faster turnaround times to boost overall productivity.

3. Complex Shapes and Geometries

5-axis simultaneous contouring outperforms conventional machining with the ability to create complex shapes and geometries. The simultaneous control over all five axes provides the flexibility to produce intricate designs. This is crucial for part design

4. Improved Finish

The consistent tool-to-workpiece contact in 5-axis contouring ensures a superior blending from operation to operation. By minimizing the need for secondary finishing processes, simultaneous contouring enhances aesthetics and improves the overall functionality and lifespan of the part.

Supported Machining Applications

The capabilities of 5-axis simultaneous contouring extend to various industries and applications, giving it an advantage over traditional machining processes. Its unique ability to create high-precision complex shapes lends itself to several innovative applications.

1.Aerospace Components

1.Aerospace Components

For aerospace machine shops, manufacturing parts like turbine blades, airfoils, and other complex aerodynamic components often requires high-precision machining of intricate geometries. The 5-axis simultaneous contouring technique allows the production of these components with a single setup, ensuring high-quality surface finishes and precise dimensions, both critical factors in aerospace applications.

2.Automotive Parts

2.Automotive Parts

Automotive industry suppliers often take advantage of the capabilities and benefits of 5-axis machining equipment. Engine components, such as camshafts, crankshafts, and cylinder heads, often have intricate geometries that require precise machining. 5-axis contouring enables manufacturers to meet these demanding specifications with ease.

3.Medical Devices

3.Medical Devices

Manufacturing for the medical industry, where precision and customization are paramount, has been revolutionized by 5-axis machining of complex surgical instruments. The process ensures the accurate and efficient production of high-stakes components, such as custom prosthetics, implants, and orthopedic devices, to meet highly stringent quality standards.

4.Dies and Molds

4.Dies and Molds

Die and mold making is another area where 5-axis machining excels. The ability for die/mold machine shops to produce complex curves and contours on a single setup greatly reduces the time and cost of producing dies and molds with these characteristics.

Challenges for Manufacturers

While 5-axis simultaneous contouring has revolutionized the manufacturing industry, it introduces some challenges for machine shops and engineers. The complexities of 5-axis machining technology demand a higher level of understanding, careful management, and meticulous attention to detail in several critical areas.

1. Programming Tool Paths

Achieving programming precision for 5-axis simultaneous contouring is challenging. Generating accurate and efficient tool paths requires sophisticated CAM software and post-processor to gain a thorough understanding of the 5-axis machining process. Inaccuracies and/or a lack of post-processing can lead to suboptimal results.

2. Machine Stability

Simultaneous movement along five axes places high demands on the machine structure and casting, requiring enhanced rigidity and balance to ensure precision. Less robust machines introduce vibration or deflection that affects contouring quality.

3. Operator Skill

The operation of 5-axis machines requires skilled programmers and experienced operators who bring an advanced understanding of CNC programming, spatial awareness, and knowledge of the machining process. Without this expertise, the machine’s potential (and ROI) might remain untapped, leading to a regression where shops use the 5-axis machine tool as a 3-axis machine.

The Expanding Reach of True 5-Axis

As manufacturers and engineers embrace 5-axis machining technology, they can unlock future opportunities to push the boundaries of their production operations.

Looking ahead, simultaneous contouring will continue to support advancements in manufacturing for industries where complexity, precision, and efficiency are critical. The evolution of aerospace and medical technology will require more intricate parts, and 5-axis machining will help manufacturers address these needs.

Simultaneous contouring and true 5-axis machining embodies the cutting edge of machining technology, blending efficiency, accuracy, and versatility. Its transformative impact on industries like aerospace, automotive, and medical technology underscores its potential.

Despite its challenges, the immense benefits of this advanced manufacturing process make it integral to the future of precision machining.

Make 5-Axis Work for Your Shop

At MinHe, we partner with machine shops to turn these challenges into opportunities. If you’re looking for solutions, our 5-axis CNC machining services can help. Connect with our experts to determine how we can introduce true 5-axis machining that drives profitability for your shop.

Looking for a structured overview of 5-axis machining principles, machine types, and design tips?

Check out our Complete 5-Axis CNC Machining Guide for more insights.