In the field of mechanical machining, the pursuit of hole precision and surface quality is the core standard for measuring product performance. Boring is an indispensable finishing technique, and its core value lies in the precise correction and refinement of pre-existing holes, serving as the ultimate guarantee for achieving high-precision fit and concentricity in critical components.

What is Boring Machining?

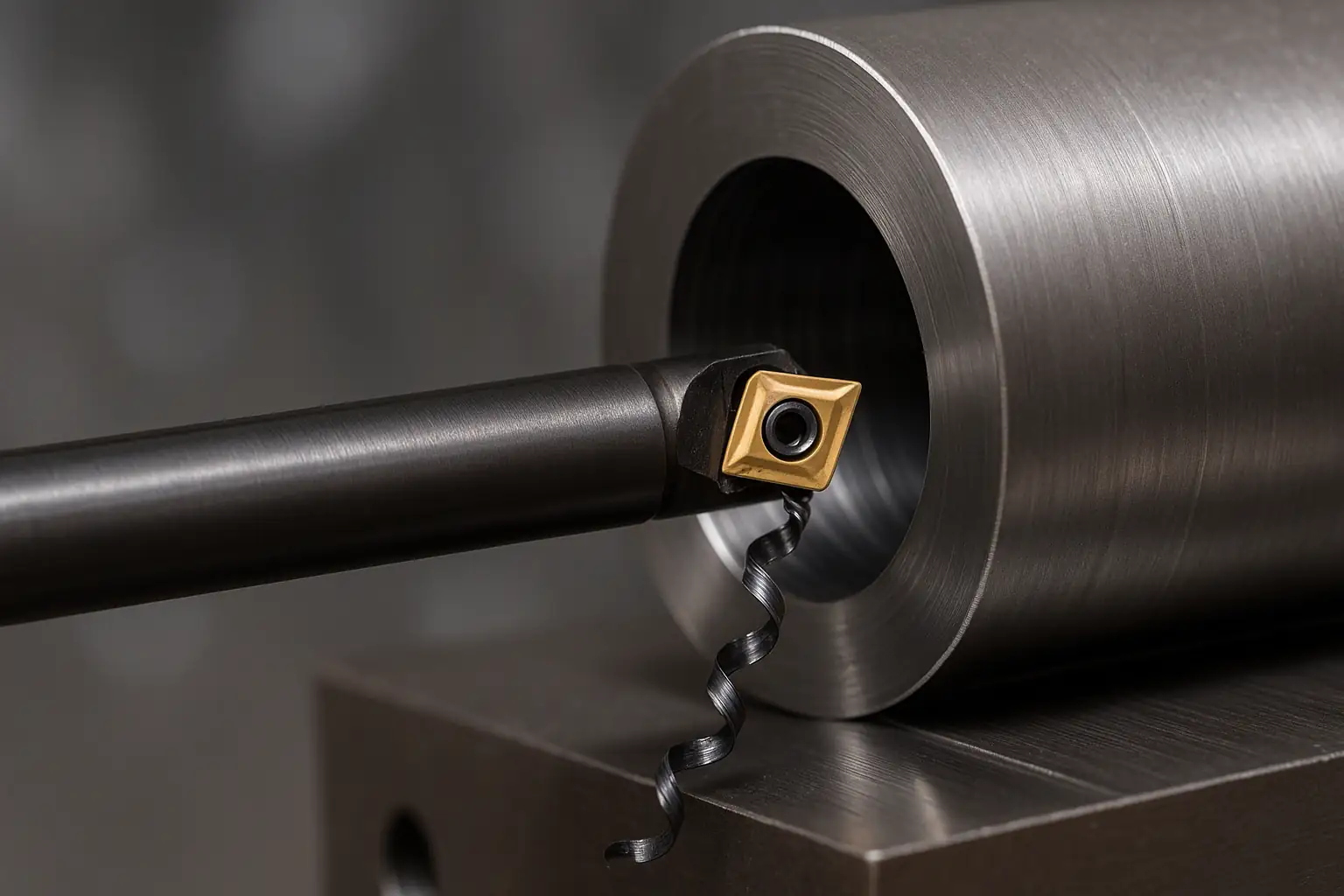

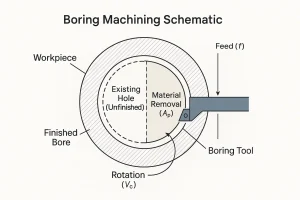

Boring is a cutting process that uses a boring tool to enlarge and refine an existing hole, aiming for extremely high geometric and dimensional accuracy. The primary goal of boring is not to create a new hole, but to ensure the precise finishing of the pre-processed hole, which is the ultimate means of ensuring high-precision fit and concentricity.

How Does Boring Machining Work?

Boring is executed not as a single action, but as a systematic progression through distinct stages. This multi-step approach is essential for mitigating the challenges of material removal while maximizing geometric precision and surface finish.

Core Stages of the Boring Process

The process systematically moves from setup to the final tolerance-defining pass:

Precision Finishing: The final stage is where the core value of boring is realized. It uses a minimal depth of cut and a micro-adjusted tool to achieve the exact dimensional tolerance (e.g., IT6) and the final required surface roughness (Ra), guaranteeing ultimate roundness and concentricity.

Preparation and Setup: The initial phase ensures the foundation for accuracy. The workpiece must be precisely aligned and securely clamped, and the appropriate tooling and initial cutting parameters (Vc, f) are selected based on the material and job specifications.

Rough Boring and Material Removal: This stage focuses on efficiency and quickly bringing the hole close to its target size. High cutting speeds and deep depths of cut (Ap) are employed to remove the majority of excess material and correct significant positional errors.

Semi-Finishing and Error Reduction: The transition stage balances removal efficiency with quality pursuit. Parameters are adjusted to moderate settings, and more precise tooling is used to refine the bore size and stabilize geometric elements like straightness and roundness.

Boring Machining Types

Boring types are diverse, categorized by geometric requirements, tool structure, and kinematics.

Through-hole Boring

Through-hole boring refines the existing bore by straight-line feeding the single-point tool axially from entry to exit. Its core function is to ensure the diameter is uniform along the entire length while correcting any remaining straightness and cylindricity deviations. As a fundamental technique, it is widely used for components like hydraulic cylinder bodies and bearing seats.

This method is typically performed on a CNC machining center.

Blind Hole Boring

Blind hole boring focuses on creating a feature with a precisely controlled depth and flat bottom within a blind hole, necessitating strict control over the axial feed stop. It is often used for valve body stops or sealing retention bores. Its technical feature is the extremely high demand for chip management, often relying on high-pressure coolant to flush chips out of the cavity.

This method is typically performed on a CNC machining center or Horizontal Boring Mill.

Stepped Boring

Stepped boring is used to machine two or more concentric diameters within a single hole by precisely controlling the tool’s radial and axial position in one clamping setup. Its function is to guarantee perfect coaxiality and accurate axial location between all finished diameter steps. This is critical for complex parts like gearbox housing bores. This technique is usually performed on a CNC machining center or Horizontal Boring Mill.

Back Boring

Back boring is utilized to cut features from the inside toward the outside of the bore, serving the purpose of resolving issues where front access is blocked or when extremely high concentricity is needed. Its technical feature is the use of a retractable specialty tool whose insert extends only after clearing the entry bore and retracts before exiting. This method is commonly performed on a Horizontal Boring Mill or CNC machining center.

Line Boring

Line boring uses an extra-long, rigid boring bar supported by precision bushings at both ends, forcing all holes to share a single, perfect common axis. Its main purpose is to calibrate and finish multiple holes separated by a long span, such as engine block main bearing bores, thereby guaranteeing the long-term operational reliability of the assembly. This process is typically performed on a Horizontal Boring Mill or a dedicated Line Boring machine.

Face Boring

Face boring, distinct from axial feeding, utilizes the boring tool’s radial feed mechanism to cut a flat surface perpendicular to the bore axis. Its function is to finish flanges or bearing seat faces, guaranteeing their perpendicularity to the bore axis, which effectively eliminates assembly stress. This method is typically performed on a Horizontal or Vertical Boring Mill.

Offset Boring

Offset boring achieves non-circular or precisely eccentric feature manufacturing by programming the boring tool to move along a precise interpolated circular path offset from the spindle’s center. Its utility is in manufacturing parts requiring precise eccentricity, such as connecting rod bores. This method is typically performed on a CNC machining center or Jig Boring Machine.

CNC Boring Machine Types

Boring operations place extremely high demands on machine rigidity and stability. Different machine types utilize unique structural designs to guarantee the required boring precision in specific applications.

CNC Machining Centers These are the versatile, mainstream platforms used for flexible manufacturing of small-to-medium-sized components. Their core lies in high integration, utilizing Automatic Tool Changers (ATC) and Automatic Pallet Changers (APC) to execute complex milling, drilling, and boring as compound operations. This makes them essential for the automated, large-scale production of automotive and aerospace components.

Horizontal Boring and Milling

Mills Horizontal Boring Mills are known for their high structural rigidity, specializing in machining box-like or long-axis heavy, deep-hole components. The horizontal spindle placement effectively counteracts the bending moments caused by long boring bars. This ensures the necessary high positional accuracy for heavy milling and deep-hole work on large gearbox housings and complex machine frames.

Vertical Boring and Milling Mills Vertical Boring Mills utilize a vertical spindle and rotating table structure, making them suitable for large-diameter, short-axis disk or ring-shaped parts. This design naturally provides high rigidity and self-centering advantages, allowing them to maintain outstanding roundness precision while performing efficient turning, facing, and fine boring. Though often called boring mills, their layout and function integrate characteristics of large lathes, making them key for power generation components and large ring workpieces.

Jig Boring Machines The design goal of Jig Boring Machines is to achieve extreme positional accuracy. They operate using high-precision linear scales and thermal stabilization systems, ensuring that positional tolerance is prioritized over hole diameter tolerance. This machine is critical for manufacturing precision fixtures, gauges, molds, and tooling, where the absolute geometric relationship between features is paramount.

Floor-Type Boring Mills These are specifically designed to process extra-large, extremely heavy, and irregularly shaped workpieces. Their core principle is that the workpiece remains fixed on the floor while the spindle travels along guideways, offering an almost unlimited working envelope. Besides boring, they handle large-scale heavy milling and facing, widely applied in shipbuilding, heavy machinery frames, and energy infrastructure.

Fine Boring Machines These are dedicated finishing machines whose operation is strictly confined to the final finishing pass. Their technical advantage stems from using high-speed spindles and air-bearing or hydrostatic guideways, which completely eliminate friction and thermal deformation. This extreme stability is key to guaranteeing IT5 grade tolerances and mirror-level surface quality, often used for the highest precision requirements in hydraulic components and precision valve seats.

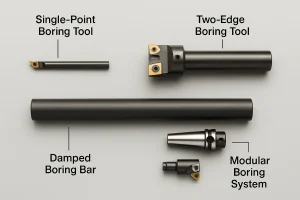

Boring Machining Tools

The precision of boring depends entirely on its core component: the boring bar. This bar must possess high static and dynamic rigidity and strong anti-vibration properties, and is typically equipped with a micro-adjustment mechanism to ensure the final dimensional accuracy.

- Single-Point Boring Tool (Fine Finishing): These tools hold a single cutting insert and are used for achieving the utmost finishing precision (IT6 or better) and the finest surface finish. Their adjustability allows for micrometer-level control over the final diameter.

- Two-Edge Boring Tool (Roughing/Semi-Finishing): These tools utilize two opposing inserts, which are primarily used for material removal efficiency where the tolerance is looser. The two edges balance the radial cutting forces, offering stability during initial, heavier cuts.

- Damped/Anti-Vibration Boring Bar (Deep Holes): Mandated for operations where the length-to-diameter ratio (L/D) exceeds 4:1. These specialized bars incorporate internal mechanisms (e.g., tuned mass dampeners) to absorb chatter and vibration, which is crucial for maintaining tolerance and surface quality in deep or slender bores.

- Modular Boring System (Versatility): These systems use interchangeable shanks, heads, and extensions, allowing for the boring bar assembly to be quickly customized to fit a wide range of hole sizes and depths, maximizing the versatility and utilization of a single tool system.

Applicable Workpiece Materials for Boring?

Boring is a precision finishing process, making it essential for a wide range of materials where high performance, tight tolerance, and superior surface integrity are required.

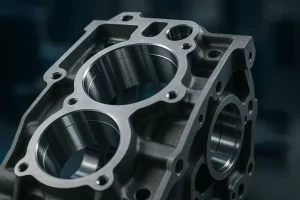

- Cast Iron and Carbon Steel: This is the most common application. Boring is the standard practice for ensuring the tight fit tolerances required for bearing seats and bushing fits in components like engine blocks and gearbox casings.

- Hardened Steels and High-Strength Alloys: For materials that have been heat-treated, boring is one of the few finishing methods capable of achieving fine tolerances. It requires CBN (Cubic Boron Nitride) inserts for stable, high-speed cutting to maintain material integrity.

- Non-Ferrous Metals (Aluminum, Copper, Bronze): Boring provides the excellent surface finish critical for sealing integrity in hydraulic and aerospace systems. These applications typically mandate PCD (Polycrystalline Diamond) tooling for best results.

- High-Temperature/Nickel Alloys (e.g., Inconel): Common in aerospace, boring is key for precisely controlling tolerances in turbine components and combustors, where these materials are notoriously difficult to machine.

- Titanium Alloys: Used extensively in medical and aerospace fields. Boring is necessary to achieve the dimensional accuracy required for critical structural elements, managing this material’s poor thermal conductivity during the process.

- Plastics and Composites: Boring is sometimes used for the final sizing and surface finishing of critical bore diameters in high-performance polymer components to ensure functional fit while carefully managing thermal deformation.

When to Perform Boring Machining

Boring is not the primary method for creating a hole; instead, it is a tool for finishing and correction. It is typically implemented in the final or penultimate stage of workpiece machining to ensure the highest precision requirements are met. The key situations that necessitate boring machining include:

- When Extreme Dimensional and Geometric Precision is Required: Boring is mandatory when hole tolerances are exceptionally tight (e.g., IT6 grade or higher) and crucial for achieving a precision fit (e.g., bearing seats, dowel pin holes).

- For Correcting Pre-existing Defects: When preceding operations like casting, forging, or drilling leave behind errors in straightness, roundness, concentricity, or position, and these defects exceed the allowed tolerance, boring is the definitive corrective measure.

- In Large Diameter or Deep Hole Machining: For holes with a large diameter or a high length-to-diameter ratio, conventional drilling or reaming struggles to guarantee accuracy. Boring, with its adjustable single-point cutting mode, provides superior control over cutting forces and vibration.

- To Improve Surface Finish: Boring is used for the final pass when an extremely low surface roughness (Ra value) is required for sealing or smooth sliding fits.

In essence, the optimal time for boring machining is when the demand for precision outweighs the consideration of cost and speed, and the quality of the existing hole fails to meet the design specifications.

Boring Machining Key Machining Parameters

The parameter control strategy consistently prioritizes stability over efficiency to safeguard accuracy, aiming to minimize dynamic forces and thermal effects during the finishing process.

Cutting Speed

To ensure an optimal surface finish, a higher surface speed (vc) must be maintained during finish boring passes. This higher speed promotes stable cutting action and minimizes built-up edge formation.

Feed Rate and Depth of Cut

These two parameters are kept minimal to control forces and precision:

- Feed Rate (f): Must be set to a minimal value to strictly control the resultant surface roughness (Ra).

- Depth of Cut (ap): This value is also kept minimal, specifically to reduce the cutting force to the lowest possible level, thereby eliminating potential workpiece elastic deformation and ensuring final dimensional accuracy.

Boring Machining Advantages

The core advantage of boring technology lies in its unparalleled precision control, which stems from its singular cutting mode.

- Superior Defect Correction: It effectively corrects both positional errors (like bore center deviation) and geometric errors (like roundness, straightness, and concentricity) inherited from prior operations (drilling, casting), serving as the ultimate means to guarantee hole quality.

- Precision Enhancement: Achieves significantly higher dimensional accuracy (easily reaching IT6 or better) and concentricity than other processes, making it the method of choice for critical fit holes.

- Excellent Surface Finish: Fine boring can reduce the resultant surface roughness (Ra) to extremely low levels, satisfying the stringent requirements for sealing integrity and smooth sliding fits.

- Adjustability and Versatility: The micro-adjustment mechanism on boring tools allows operators to make micron-level diameter adjustments, easily accommodating custom or non-standard hole sizes with high precision.

Boring Machining Limitations

The main limitations of boring are rooted in its demanding requirements for equipment and time, as well as inherent operational challenges.

- High Cost and Low Efficiency: The process is time-consuming and heavily relies on high-rigidity CNC equipment and expensive specialized boring tooling (especially damped boring bars), resulting in a higher unit cost.

- Application Scope Limitation: Due to high costs, boring is primarily confined to high-value, high-performance critical components and is generally not feasible for high-volume production with loose tolerances.

- High Sensitivity to Vibration: The inherent low dynamic rigidity of long boring bar overhangs makes the system highly prone to chatter. This demands both high operator experience and strict parameter control for mitigation.

- Chip and Coolant Management Challenges: Particularly in deep or blind holes, the tight cutting zone makes chip evacuation difficult. This necessitates complex high-pressure through-spindle coolant systems, adding to the equipment complexity and maintenance demands.

Boring Machining Applications

Boring technology forms the cornerstone of high-reliability industries. It is widely applied in sectors with stringent performance requirements where concentricity, alignment, and precise fit are non-negotiable standards:

- Automotive and Engine Manufacturing: Essential for achieving the required tolerances in internal combustion engines. Key applications include main bearing bores in engine blocks, camshaft bores, and precision sizing of cylinder liner seats.

- Aerospace and Defense: Used for components where failure is catastrophic. This includes precise fit holes in turbine casings, alignment bores for landing gear components, and tight tolerance holes in actuator housings and fluid control valves.

- Heavy Machinery and Power Generation: Mandated for large, critical systems. Applications involve finishing bearing seat bores in large gearboxes, precisely aligning hydraulic cylinder bores, and machining accurate holes in turbine rotors and industrial pump housings.

- Molds, Dies, and Tooling: Critical for the fabrication of complex tooling where positional accuracy is paramount. Boring is used to finish precise pin holes, bushing seats, and guide holes in large mold plates and fixtures to ensure assembly alignment.

- Fluid Power and Hydraulics: Vital for efficiency and leak prevention. It is used to achieve the required surface finish and roundness in valve bodies and pump housings to ensure perfect sealing and smooth operation of pistons and spools.

Critical Challenges in Boring Machining

Addressing the inherent instability and thermal effects of deep-hole machining is critical to achieving specified geometric tolerances and surface quality.

Vibration Control

The greatest operational obstacle in high-precision boring is managing and eliminating chatter.

- Cause: The long overhang of the boring bar inherently creates a system prone to instability, especially when the length-to-diameter (L/D) ratio is high.

- Mitigation: The only reliable engineering solution is the mandatory use of damped boring bars (tools incorporating tuned mass or heavy metal construction), a necessity for high L/D ratio holes to absorb chatter and maintain precision.

Chip and Coolant Management

Effective chip evacuation and thermal control are critical process determinants.

- The Challenge: In deep and blind holes, the constrained cutting zone makes natural chip evacuation extremely difficult, leading to chip re-cutting, surface damage, and rapid tool wear.

- Solution: A high-pressure through-spindle coolant system is required. This system provides the hydraulic force necessary to immediately flush chips out of the bore, while also controlling heat to prevent thermal deformation of the tool and workpiece.

Measurement and In-Process Calibration

Achieving and verifying micro-level precision requires overcoming significant metrology challenges.

Mitigation: The process relies heavily on high-precision setting equipment to pre-set the tool outside the machine and often requires on-machine probing or specialized internal metrology tools (like bore gauges) to verify final size before unclamping the workpiece.proper cooling, this heat causes thermal deformation in both the workpiece and the boring bar, directly impacting final dimensional accuracy.

The Challenge: Directly measuring the finished bore diameter in-process (while the part is still clamped) is difficult, particularly in deep or complex geometries. Any thermal change in the part after cutting (thermal drift) will instantly compromise the final measurement.

Boring Machining Process Comparison

To fully appreciate the role of boring, it must be compared to other common hole-making and finishing processes. Boring is fundamentally a precision refinement technique, not a high-volume stock removal process.

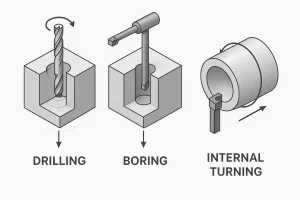

Boring vs. Drilling

Drilling is the primary method for creating the initial hole, whereas boring is the method for correction and finishing. The key difference lies in the tool and achievable tolerance. Drilling uses a multi-point, fixed-diameter tool, resulting in loose tolerances (IT10−IT13) with poor roundness and finish. In stark contrast, boring uses a single-point, micro-adjustable boring bar. This adjustability allows boring to achieve high precision (IT6 or better) and is the only reliable way to correct geometric errors like positional deviation, straightness, and concentricity inherited from the drilling process.

Boring vs. Turning

Both processes use a single-point tool to refine an internal diameter, but they differ significantly in machine tool kinematics and structural rigidity. Internal turning is typically performed on a lathe, where the workpiece rotates and the tool remains stationary. While effective for simple cylindrical parts, its precision is often limited by the lathe cross-slide for adjustment and general tool post rigidity. Boring, performed on massive machining centers or dedicated boring mills, benefits from superior structural rigidity, which is essential for maintaining accuracy in deep holes. Furthermore, the specialized micro-adjustment mechanisms on boring heads provide far finer, more repeatable control over the final diameter than standard lathe tool setups, giving boring a distinct advantage in achieving ultimate positional accuracy across the machine envelope.

Conclusion

Boring is the critical finishing technique required to achieve the highest precision hole diameters and geometric tolerances in mechanical components. It relies on high-rigidity equipment and precise tooling to perform accurate correction of pre-existing holes, effectively eliminating positional and roundness errors.

Though this process is high-cost and time-consuming, it serves as the ultimate process guarantee for ensuring superior concentricity and long-term reliability of critical fit components across aerospace, automotive, and heavy machinery sectors. Boring is the foundation of precision engineering.

Contact Us

Need to solve your precision hole machining challenges and achieve strict geometric tolerances and surface finish requirements?

Please send us your engineering drawings and material specifications.

We will leverage our practical machining expertise to deliver a customized boring process design and technical support.

We look forward to partnering with you to ensure the precision and long-term reliability of your critical components.