Drilling is a fundamental cutting process that uses a rotating tool to create cylindrical holes in a workpiece. While this process has a long history, it evolves significantly when combined with computer numerical control (CNC) technology. This leads to the question, what is CNC drilling? CNC drilling is an automated and precise manufacturing method that uses a computer program to control the drill bit’s movement, ensuring perfect hole alignment and dimensional consistency.

However, when combined with Computer Numerical Control (CNC) technology, it transforms into a highly automated and precise manufacturing method. CNC drilling uses a computer program to accurately control the drill bit’s movement, removing material at a predetermined location and depth with extreme speed and precision. This ensures perfect hole alignment, dimensional consistency, and surface finish, meeting the stringent precision demands of modern industries.

The Origins of CNC Drilling

The origin of CNC drilling can be traced back to the mid-20th century, with the birth of numerical control technology. Initially, early CNC machines were primarily for simple milling and turning. However, as computer technology and servo systems rapidly advanced, engineers began applying automated control to drilling as well.

This shift was a game-changer. Drilling no longer depended on an operator’s experience; a computer program now executed the task with precision. This significantly boosted production efficiency and product quality. From the first bulky equipment to today’s compact, multi-axis drilling centers, the technology has evolved continuously, becoming a vital part of precision manufacturing.

How Does CNC Drilling Work?

CNC drilling’s precision comes from a rigorous, four-stage process.

1. The Preparation Phase

Before machining begins, the engineer selects the most suitable drill bit and fixture based on the workpiece material, hole diameter, and depth. For this reason, the drill bit’s material (such as high-speed steel or carbide) and type (like a twist drill or center drill) directly impact machining efficiency and hole quality. In addition, a stable fixture is also essential to prevent the workpiece from moving or vibrating during high-speed cutting, as this is a prerequisite for ensuring positional accuracy.

2. The Programming Phase

This stage is the core of CNC drilling’s automation. An operator or programmer uses CAD/CAM software to translate the 3D design into a set of instructions the machine can understand—G-code and M-code. G-code defines the tool’s movement and position, such as the coordinates (X, Y, Z) for the hole. M-code controls the machine’s auxiliary functions, like spindle start/stop, coolant on/off, and automatic tool changes.

3. The Machining Phase

Once the program is loaded, the actual machining begins. The machine precisely controls the spindle’s speed and the tool’s feed rate based on the G-code instructions. During drilling, effective chip evacuation is crucial, especially for deep holes. Specialized canned cycles, such as peck drilling, automatically retract the tool to clear chips, preventing blockages and tool damage.

4. The Post-Processing Phase

After machining is complete, the workpiece undergoes final processing to meet finished part requirements. This stage typically includes three key steps. First, we deburr the part to remove any rough edges. Then, we use precision measuring tools like calipers or micrometers to measure the holes, ensuring all dimensions are within tolerance. Finally, we apply any necessary surface treatments for final assembly or functional needs.

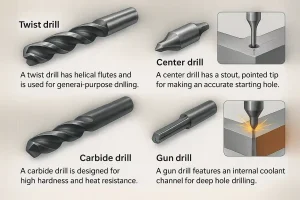

Different Types of CNC Drill Bits

The versatility of CNC machining depends heavily on tool selection. Therefore, the type of drill bit directly influences hole quality, efficiency, and material suitability. For this reason, understanding the characteristics of different drill bits is key to a successful drilling operation.

Twist Drill

This is the most common and versatile type of drill bit, suitable for most materials and general drilling tasks. Its helical flutes are designed to effectively evacuate chips.

Center Drill

This bit is primarily used to create precise starting points or small conical holes on a workpiece. Using a center drill before a larger twist drill prevents the bit from “walking” at the beginning of the cut, thereby improving hole position accuracy.

Carbide Drill Bit

Known for their exceptional hardness and wear resistance, carbide drill bits are ideal for machining hard materials like stainless steel and cast iron. They can operate at higher cutting speeds, significantly boosting production efficiency.

Gun Drill

A gun drill is a specialized tool for deep-hole drilling. It features a unique internal channel that delivers high-pressure coolant to the cutting tip while simultaneously flushing chips out through an external channel, ensuring high precision and efficient chip evacuation in extremely deep holes.

Drill Bit Materials & Coatings

Beyond the type of drill bit, the material it’s made from and the coating applied to its surface are critical factors that influence its performance. They determine what material it can machine, how fast it can operate, and how long it will last.

Drill Bit Materials

- High-Speed Steel (HSS) is the most common drill bit material, widely used for general-purpose drilling in softer materials like steel and aluminum. This is because it’s both tough and inexpensive. However, its lower heat resistance and hardness make it unsuitable for high-speed cutting.

- Carbide: As the name suggests, this material is extremely hard and can withstand much higher cutting temperatures and speeds. It’s ideal for machining tough or abrasive materials like stainless steel, cast iron, and titanium alloys, significantly improving production efficiency and hole quality.

- Polycrystalline Diamond (PCD) is one of the hardest known materials. PCD-tipped drill bits are ideal for machining non-metallic materials like glass, ceramics, composites, and graphite, as they deliver exceptional precision and a superior surface finish.

Drill Bit Coatings

A drill bit coating can be thought of as its “armor.” It’s an extremely thin, yet incredibly hard, film applied to the bit’s surface using a specialized process. The primary functions of this coating are:

- Increased Hardness and Wear Resistance: The coating’s hardness is often far greater than the base material, making the drill bit more resistant to wear and extending its tool life.

- Reduced Friction: A coating makes the bit’s surface smoother, which lowers the heat generated during cutting and prevents chips from sticking to the tool.

- Higher Cutting Speeds: Thanks to their enhanced performance, coated drill bits can be used at higher speeds and feed rates, dramatically increasing production efficiency.

Drilling Operation Types

The power of CNC drilling lies not just in its ability to create simple holes but also in its capacity to perform a variety of advanced operations to meet more complex machining needs. Each of these operation types has a specific purpose and is crucial for achieving perfect hole quality and functionality.

Peck Drilling

Peck drilling is a CNC drilling operation designed specifically for deep hole drilling. Unlike drilling straight through, we advance the drill bit into the material in small increments, then fully or partially retract it from the hole. This repeated pecking motion effectively breaks up and clears chips, preventing tool clogging and overheating. For drilling deep holes where the depth is more than three times the drill bit’s diameter, peck drilling is indispensable. It significantly improves hole accuracy and surface finish while extending tool life.

Tapping

After we complete CNC drilling, tapping is a subsequent precision operation we use to cut threads into the inside wall of a hole. This process typically uses a special tool called a tap. On a CNC machine, we highly automate the tapping process, with precise control over spindle speed and feed rate to ensure consistent and accurate threads. Tapping is a critical step for creating threaded holes for screws or bolts and is widely used in industries like automotive and aerospace where fasteners are required.

Boring

Boring is another drilling operation type, but its purpose is not to create a new hole; we use it for finishing an existing one. When a part requires extremely high dimensional accuracy, concentricity, or a perfect surface finish, we use a boring bar to recut the hole. Boring can correct positional or dimensional errors caused by the initial drilling and enlarge a hole to an exact tolerance. As a result, boring is often an essential post-CNC drilling step, especially when machining high-precision parts.

What is a CNC Drilling Machine?

A CNC drilling machine is an automated and precise manufacturing tool. It uses a computer program to control the drill bit’s movement, creating cylindrical holes in a workpiece. The machine’s core strength is its ability to remove material at a predetermined location and depth with extreme speed and precision based on computer instructions. This ensures perfect hole alignment and dimensional consistency, meeting the stringent demands of modern industries for high accuracy.

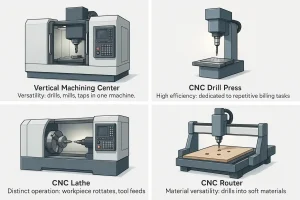

Machine Types and Functions

The power of CNC drilling lies not just in its ability to create simple holes but also in its capacity to perform a variety of advanced operations to meet more complex machining needs. To understand this versatility, let’s explore the types of machines that can perform CNC drilling.

-

-

Machining Center A machining center is the most common machine used for CNC drilling. It’s a versatile, multi-purpose tool that not only drills holes but also mills, taps, and performs other complex operations. These machines are often equipped with an automatic tool changer, allowing them to complete multiple processes in a single setup, making them a cornerstone of modern manufacturing.

-

CNC Drill Press This is a more specialized machine designed primarily for drilling. Compared to a machining center, its structure is simpler and it typically only performs cutting motions along the Z-axis. While less versatile, it is highly efficient for high-volume, repetitive drilling tasks.

-

CNC Lathe A CNC lathe’s primary purpose is turning, but many are also capable of drilling. A unique feature of drilling on a lathe is that the workpiece rotates while the drill bit typically remains stationary, which is a fundamentally different operation from a machining center.

-

CNC Router CNC routers are mainly used for cutting and carving soft materials like wood and plastic. However, they can also perform drilling operations by fitting the appropriate drill bit. They are generally not suitable for precision drilling in metal.

-

CNC Milling vs CNC Drilling: A Core Distinction

CNC milling and CNC drilling are both types of CNC machining, but they are very distinct processes. To select the right tool and method for a job, you must understand their differences.

Function and Purpose

The main purpose of CNC drilling is to create cylindrical holes in a workpiece. In contrast, CNC milling is a more versatile process. It removes material by moving a tool along multiple axes to create various shapes, planes, slots, and 3D surfaces. Simply put, drilling makes holes, while milling carves shapes.

Tooling

CNC drilling mainly uses drill bits like twist or center drills. These tools are designed for axial cutting to create holes. On the other hand, CNC milling uses a wide variety of end mills, such as flat-end, ball-end, and face mills, which can cut with their side or bottom edges.

Tool Motion

CNC drilling motion is relatively simple. The tool moves in a straight line along a single axis (usually the Z-axis). CNC milling is much more complex. The tool moves along multiple axes (X, Y, and Z) simultaneously to achieve complex shapes.

Despite their differences, modern CNC machines, especially machining centers, can perform both drilling and milling tasks, offering great flexibility.

Advantages of CNC Drilling

Here is the English version of the “Advantages of CNC Drilling” section, formatted with clear headings for each benefit.

High Precision and Consistency

One of the most critical advantages of CNC drilling is its ability to achieve exceptional accuracy. It operates based on a computer program with a digital blueprint, which virtually eliminates human error. This allows it to create holes with micron-level positional and depth control. For applications requiring strict tolerances, such as those in the aerospace or medical industries, this consistency is non-negotiable, as it ensures every part in a production run is identical and perfectly aligned.

High Efficiency and Automation

CNC drilling is a highly efficient and automated process that dramatically reduces production time. Once a machine is programmed, it can run continuously with minimal supervision. Features like automatic tool changers allow a single machine to perform multiple operations without manual intervention, such as switching from a standard drill bit to a tap for threading. This automation minimizes setup time and labor costs, leading to faster turnaround times for large-volume projects.

Ability to Machine Complex Holes

Unlike manual methods limited to straight, vertical holes, CNC technology can handle a wide array of complex drilling challenges. With multi-axis machines, it’s possible to create holes at precise angles, drill deep holes that require frequent chip evacuation (peck drilling), and even machine non-circular holes. This versatility gives manufacturers the flexibility to design and produce complex, innovative components that would be impossible with conventional tools.

CNC Drilling Applications

The unique precision and efficiency of CNC drilling make it an essential technology in a wide range of industries where accuracy is paramount.

Aerospace

In the aerospace industry, safety and reliability are non-negotiable. Manufacturers use CNC drilling to create precise holes in aircraft fuselages, engine components, and landing gear. These holes must meet extremely tight tolerances to ensure that parts fit together perfectly and can withstand immense stress and pressure.

Medical Devices

For medical devices, the biocompatibility and functionality of parts depend on their precision. CNC drilling manufactures bone screws, surgical instruments, and implantable devices. This process creates tiny, burr-free holes in materials like titanium and stainless steel, which is vital for the safety and success of these products.

Electronics

The electronics sector relies on CNC drilling to manufacture printed circuit boards (PCBs). High-speed micro-drilling creates thousands of tiny, precise holes in a single board. This enables the flow of electrical signals and ensures the functionality and reliability of products ranging from smartphones to complex computing systems.

Other Precision Fields

Beyond these major industries, CNC drilling is fundamental to many other sectors. It’s used in the automotive industry for engine blocks and transmission components. In the energy sector, it drills parts for turbines and oil and gas equipment. It also helps in tool and die making to create highly accurate molds and fixtures.

Maintenance and Troubleshooting

This section aims to solve your CNC drilling problems. We’ll analyze the root causes of common issues and provide immediately applicable solutions.

How to Prevent Drill Overheating?

Drill bit overheating is a common pain point in CNC drilling, as it can accelerate tool wear and degrade hole quality. To solve this, a multi-faceted approach is required. First, check your program to ensure the spindle speed and feed rate are appropriate for the workpiece material and drill bit type. After all, an overly high spindle speed for some materials generates excessive heat. In addition, coolant plays a vital role in CNC drilling. It effectively dissipates cutting heat, lubricates the tool, and helps evacuate chips. Therefore, make sure your cooling system is functioning properly and that the coolant is directed straight to the cutting zone. Furthermore, selecting a drill bit suitable for the material is crucial. For example, when machining hard materials, a carbide drill bit will be more heat-resistant and durable than a standard high-speed steel bit. Finally, a dull drill bit requires more force to cut, which in turn generates more heat. Consequently, regularly inspecting and replacing worn-out drill bits is the simplest way to prevent overheating and ensure consistent quality.

How to Ensure CNC Drill Accuracy?

The key selling point of CNC drilling is its high precision, but that accuracy can be compromised without proper management. To ensure every hole is accurate, you should focus on these key practices. To begin with, utilize spot drilling. Before using a standard drill bit, use a center drill to create a precise starting point. This effectively prevents the drill bit from “walking” upon entry, which is the easiest way to guarantee accurate hole placement. In addition, even the most advanced CNC machines require periodic calibration to ensure the precision of their motion systems. This includes checking the parallelism of axes and the runout of the spindle. Moreover, the runout of the drill bit is a critical factor affecting accuracy. Using high-quality ER collets or hydraulic tool holders can effectively reduce runout and keep the drill bit centered as it rotates. Lastly, you must properly secure the workpiece. Ensure it is firmly clamped in the vise or fixture without any movement or vibration. After all, any subtle motion can cause a deviation in hole position or an inaccurate diameter.

Conclusion

CNC drilling is more than just a simple manufacturing process; it is a cornerstone of modern precision manufacturing. Through the precise control of computer programs, it achieves unparalleled levels of accuracy, efficiency, and consistency that are impossible with traditional methods, making it indispensable in high-stakes fields like aerospace, medicine, and electronics.

Understanding how CNC drilling works, mastering the properties of different drill bits and materials, and knowing how to troubleshoot common issues are all essential skills for professionals and enthusiasts alike. By continuously learning and practicing, you can fully leverage this powerful technology to turn designs into reality and produce high-quality, precise components.

Call to Action: If you have any CNC drilling challenges or project needs, please do not hesitate to contact us. Our team of experts is ready to provide professional solutions and technical support to help you succeed.