CNC technology is at the core of the manufacturing industry, improving efficiency and reducing costs through high-precision and automated control. CNC refers to computer program control, and CNC turning is a process based on this, performing subtractive and machining operations. Next, we’ll explain the definition of CNC turning, its operating principles, key lathe components, lathe types, operating methods, advantages, applications, and suitable materials.

What is CNC turning?

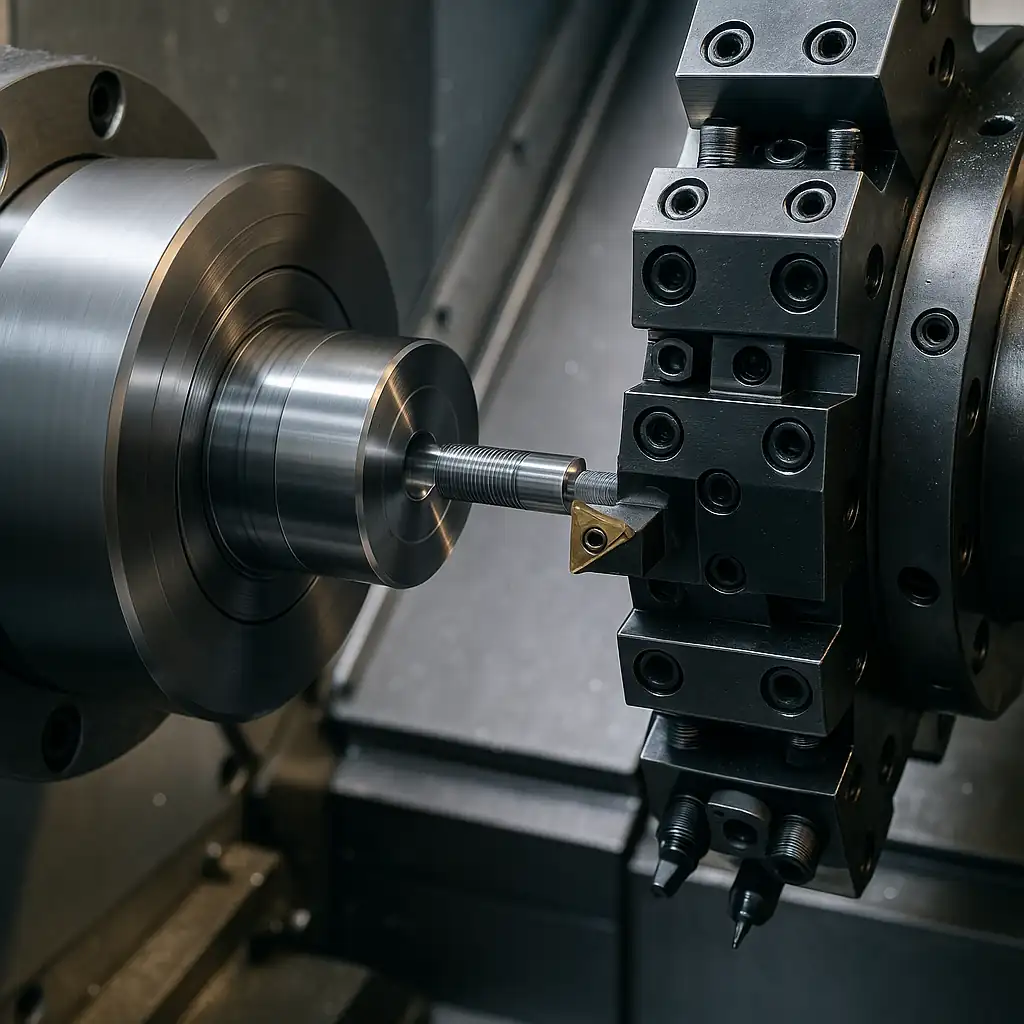

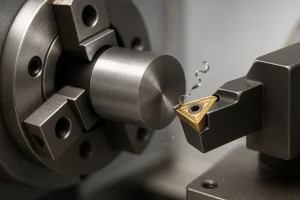

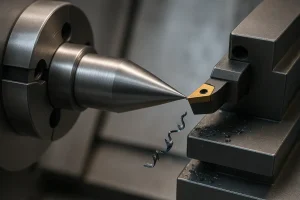

CNC turning is a highly automated subtractive manufacturing process. It operates by placing a workpiece on a high-speed spindle, while a computer-controlled machine tool precisely guides the cutting tool to cut the material into the desired shape.

It can efficiently produce high-precision cylindrical parts, as well as handle certain geometries and internal and external threads.

How Does CNC Turning Work?

Before machining a material, engineers use specialized software to generate a detailed program based on the product’s 3D model. This program, primarily composed of G-code, contains precise instructions for controlling tool paths, cutting speeds, feed rates, and spindle rotation, systematically controlling the entire production process.

Once the program is complete, the operator securely clamps the workpiece in the spindle chuck. As the program starts, the spindle rotates the workpiece at a set speed. Simultaneously, the cutting tool moves with pinpoint accuracy along the X-axis (controlling the diameter) and the Z-axis (controlling the length) according to the program’s instructions. Notably, the turret on a CNC lathe or turning center holds various tools, all controlled by the computer program and code. Machines that can accommodate more tools are more advanced and powerful, making them better suited for complex designs.

This process progressively removes material until the workpiece reaches the final dimensions and geometry required by the design. The entire machining process is monitored in real time by engineers, and a closed-loop feedback system continuously corrects tool position to achieve extremely high precision and consistency in the final product.

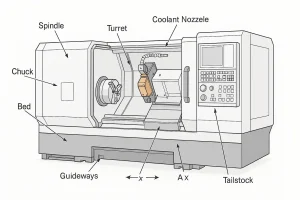

Key Components of a CNC Lathe

Here are the key components of a CNC lathe and their functions:

Spindle

The spindle is responsible for clamping and rotating the workpiece at high speed. Its rotational speed and precision directly affect the cutting efficiency and the final surface quality of the part.

Chuck

The chuck is used to securely hold and fix the workpiece to the spindle. A stable chuck prevents the workpiece from shifting during high-speed rotation and cutting.

Turret

The turret is a rotating device that can hold multiple cutting tools. It is capable of quickly switching tools according to program instructions to complete different machining tasks.

Bed

The bed is the base structure of the machine, providing stable support. Its rigidity is crucial for ensuring the precision of the entire machining process.

Guide Rails & Servo Motors

Guide rails provide a linear path for the precise movement of the cutting tool, while servo motors are responsible for driving the tool along the X and Z axes to achieve micron-level positioning.

Tailstock

The tailstock provides additional support when machining long or heavy workpieces.

Coolant System

The coolant system cools and lubricates the tool and workpiece during the cutting process.

Control System / Operating Panel

This is the brain of the CNC machine. The operator uses it to input programs, monitor the machining process, and adjust parameters.

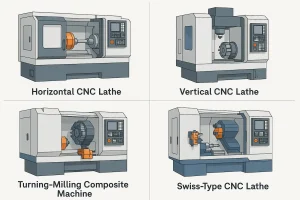

Common Types of CNC Lathes

There are several types of CNC lathes, each with a unique design and application. Choosing the right machine can maximize production efficiency and part quality.

Horizontal CNC Lathe

This is the most common and versatile type of CNC lathe. Its spindle is oriented horizontally, and the cutting tool moves along the horizontal plane to turn the workpiece. Horizontal lathes are suitable for the standard turning of most small to medium-sized parts.

Vertical CNC Lathe

Unlike a horizontal lathe, a vertical lathe has a vertically oriented spindle. This design utilizes gravity, making it particularly well-suited for turning large, heavy, and short parts, such as discs or rings. It also simplifies the process of clamping and loading the workpiece.

Turning-Milling Composite Machine

A turning-milling composite machine, also known as a turning center, is a highly integrated CNC lathe. It not only has turning functions but also incorporates a milling spindle. This means a single machine can perform complex turning, milling, and drilling tasks in one setup, greatly improving efficiency and precision.

Swiss-Type CNC Lathe

A Swiss-type lathe is a specialized CNC lathe designed for machining small-diameter, long, and highly precise parts. Its core feature is a “sliding headstock.” During the turning process, the workpiece moves axially through a guide bushing, providing continuous and close-range support for the tool, which effectively prevents deformation of long, slender parts.

Types of CNC Turning Operations

CNC lathes are capable of performing a wide variety of operations to meet different part machining requirements. Here are some of the common types:

Turning

This is the most basic turning operation. The tool moves along the axial direction of the workpiece, removing material from the outer surface to reduce its diameter and form a cylinder, a step, or a taper. It is the foundation for machining any external contour.

Boring

Boring is used to enlarge an existing hole in a workpiece. Unlike drilling, boring can produce holes with precise dimensions and smooth surfaces, and can also machine internal features.

Parting

The parting operation is used to cut off a finished part from the raw bar stock. This is typically the final process in a machining sequence, requiring the tool to precisely cut into and separate the workpiece.

Grooving

Grooving is the operation of creating a narrow groove of a specific width and depth on the inner, outer, or face surface of a workpiece. The tool shape matches the groove shape, and it’s often used for fitting O-rings or snap rings.

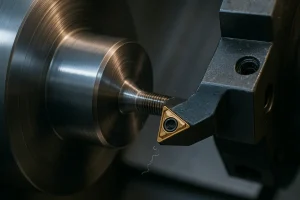

Threading

Threading is used to machine threads on the internal or external surfaces of a workpiece. This process requires the spindle’s rotation and the tool’s axial movement to be strictly synchronized to form an accurate pitch.

Drilling

Drilling is the process of using a drill to drill a hole along the center axis of a workpiece. This is usually a preparatory step for subsequent internal hole machining, laying the foundation for precise machining.

Knurling

Knurling is the process of pressing a specific patterned texture, such as a diamond or straight line pattern, onto the outer surface of a workpiece. It’s important to note that this is a cold-forming process, not a cutting process that removes material.

Key Advantages of CNC Turning

High Precision and Consistency

Through computer programming, CNC turning can achieve extremely tight dimensional tolerances and excellent surface finish, reducing human error. In mass production, this can ensure that each part has similar quality and dimensions, which is crucial for product reliability

Efficiency and Automation

Thanks to the support of CNC technology, the process is automated, which improves work efficiency

Versatility and Complexity

CNC turning can process not only simple cylinders but also complex geometries, including tapers, unique profiles, and internal and external threads. It is compatible with a wide range of materials, from various metals to engineering plastics, providing many possibilities for part design.

Cost-Effectiveness

Automation reduces labor costs, while its high precision also greatly reduces material waste and the number of defective parts.

Typical Applications of CNC Turning

CNC turning is widely used in many industries that require precision cylindrical parts. Here are some specific examples:

Aerospace Industry

In the aerospace sector, where precision and reliability are paramount, CNC turning is a core technology for manufacturing critical parts. This includes components for landing gear, engine bushings and shafts, and various high-precision connectors.

Automotive Industry

CNC turning operations are pretty common in the manufacture of components of automobiles that help improve the functioning of the vehicle, a key process in the production of precision components for engines, drivetrains, and chassis. Applications include the manufacture of high-precision pistons, drive shafts, gears, and various connectors.

Medical Devices

The medical field has strict requirements for material biocompatibility and micron-level precision. Here, CNC turning is used to produce surgical instruments, orthopedic implants (such as screws), dental tools, and precise fluid control fittings.

General Machinery and Electronics

In the broader industrial and consumer electronics sectors, CNC turning is also vital. It’s often used to manufacture bearing housings, bushings, various threaded fittings, and precision connectors and housings for electronic devices.

Suitable Materials for CNC Turning

The range of materials that can be machined with CNC turning is extensive, covering everything from common metals to high-performance plastics. Choosing the right material is crucial for ensuring both part performance and machining efficiency.

Metals

- Stainless Steel: Excellent corrosion resistance and high strength. It is commonly used in medical instruments, food processing equipment, and high-stress structural components.

- Aluminum Alloys: Lightweight, highly conductive, and easy to machine. It is the material of choice for aerospace parts, automotive components, and electronics housings.

- Copper & Brass: These materials offer outstanding electrical and thermal conductivity and are easy to cut. They are widely used for connectors, valves, and electrical components.

- Carbon & Alloy Steel: These provide high strength, good wear resistance, and are relatively low-cost. They are standard materials for manufacturing shafts, gears, and machine structural parts.

- Titanium Alloys: Known for their excellent strength-to-weight ratio and biocompatibility, though they are more difficult to machine. They are primarily used in aerospace and high-end medical implants.

Plastics & Polymers

- Nylon: Offers good wear resistance and self-lubricating properties. It is often used for making bearings, bushings, and gears.

- POM (Acetal/Delrin): A rigid and hard engineering plastic with excellent machining properties. It is frequently used for mechanical parts requiring precise fit.

- PEEK: A high-performance engineering plastic with outstanding resistance to high temperatures and chemicals. It is used for high-end applications in aerospace and medicine.

MinHe’s CNC Turning Capabilities

Once you understand CNC turning, you’ll know if it’s right for your manufacturing needs. The next step is finding the right partner to help you complete your design.

MinHe has over 20 years of experience in CNC turning and is ISO 9001 certified. You can be assured that our products meet high industry standards.

We specialize in machining complex geometries and a wide range of materials, including stainless steel, aluminum alloys, titanium alloys, and high-performance engineering plastics. With advanced CNC equipment and efficient automated processes, we can provide our customers with high-quality parts from prototype to mass production.

Contact us today for an instant quote.