Throughout the history of human civilization, copper has played a crucial role. From prehistoric tools and adornments to the modern arteries driving global information, energy, and precision manufacturing, this unique red metal has never been absent. With its outstanding electrical and thermal conductivity, corrosion resistance, and excellent machinability, copper has become an indispensable strategic material in modern industry and daily life. This article will comprehensively analyze copper’s definition, long history, complex manufacturing process, main types, properties, advantages, and limitations, and explore its unique strengths and wide-ranging applications in the field of precision machining.

What Is Copper

Copper is a chemical element with the symbol Cu (derived from the Latin cuprum) and atomic number 29. It belongs to Group 11 (Transition Metals) of the periodic table, alongside gold (Au) and silver (Ag), collectively known as the “coinage metals” family, and is renowned for its high electrical conductivity.

Key Characteristics of Copper:

- Electrical and Thermal Conductivity: Copper is the best commercial conductor of electricity and heat after silver, which is the foundation of its unshakeable position in power and thermal management fields.

- Ductility and Malleability: Copper possesses excellent ductility and malleability, allowing it to be easily drawn into extremely fine wires (wire rods) or rolled into very thin sheets (foil), greatly facilitating various forming and processing needs.

- Color and Luster: Pure copper has a distinctive red or rose-red color with a bright metallic luster. When exposed to air, it gradually oxidizes to form a protective patina, giving it a special historical beauty and durability.

Brief Differences from Other Metals

Compared to Carbon Steel:

Copper’s density (approximately 8.96 g/cm³) is higher than ordinary carbon steel, but its strength is much lower than steel. Copper is iron-free, thus offering excellent corrosion resistance, especially in humid environments, while steel has poor electrical conductivity.

Compared to Aluminum:

Aluminum is much lighter than copper (density approximately 2.70 g/cm³), but for the same volume, copper’s electrical and thermal conductivity is far superior to aluminum’s, and its mechanical strength and fatigue resistance are also generally better.

History of Copper

Early Use of Copper

Archaeological evidence suggests that human use of copper dates back about 10,000 years to the late Neolithic period (finds in Turkey, Iraq, etc.). Initially, people used native copper (red copper), which existed in its pure metallic form in nature. Due to its low hardness (Brinell hardness only about 35), it could be directly shaped into simple tools and ornaments through cold forging and hammering.

Smelting and the Copper Age

With the mastery of ore smelting technology (around 5000 BC), particularly the discovery that metal copper could be reduced by heating copper oxide ores like malachite, copper’s application saw a major leap.

- Bronze Age: The truly revolutionary breakthrough occurred when humans consciously began fusing copper with other metals (primarily tin, but also lead or arsenic) to create bronze alloys. Bronze is harder, more durable, and easier to cast than pure copper. This marked the beginning of the Bronze Age, greatly promoting the development of production tools, weapons, and ceremonial objects.

Role in Modern Manufacturing

During the Industrial Revolution, large-scale copper mining and processing technologies matured. Copper’s core role in generators, electric motors, and cables laid the material foundation for the electrical age. Today, copper remains an indispensable basic material for sectors such as electronics, communication, transportation, and new energy.

Manufacturing Process of Copper

Copper production is a complex, multi-step process designed to extract and refine high-purity metal from low-grade ore.

1. Ore Mining

The main methods for mining copper ore include:

- Open-Pit Mining: Suitable for large, shallow deposits and is currently the most prevalent mining method.

- Underground Mining: Suitable for deep-seated deposits.

- Hydrometallurgy: Suitable for low-grade ores, extracting copper directly through chemical processes such as leaching-solvent extraction-electrowinning.

2. Smelting and Purification

For copper sulfide ores, pyrometallurgy is the main process:

- Mineral Processing and Concentrate Production: The ore is crushed, ground, and subjected to flotation to obtain copper concentrate with a higher copper content.

- Smelting: Copper concentrate is melted in a furnace (such as a flash furnace) to produce copper matte (containing copper, sulfur, and iron).

- Converting: Copper matte is blown in a converter to remove sulfur and iron, resulting in blister copper (approximately 98% copper content).

- Anode Refining: Blister copper is cast into anode plates through fire refining.

- Electrolytic Refining: The anode plates are electrolyzed in a copper sulfate electrolyte, finally yielding cathode copper (high-purity refined copper) with a purity of up to 99.99% or higher. Impurities (such as precious metals like gold, silver, and platinum) are recovered from the anode sludge.

3. Processing and Post-Treatment

High-purity copper and copper alloys are further processed into various semi-finished products:

- Casting: Production of copper ingots and cast rods.

- Plastic Deformation: Production of various shapes of copper rods, tubes, sheets, foil, and wires through processes such as hot extrusion, cold drawing, and rolling.

4. Recycling and Sustainability

Copper is a metal that can be recycled indefinitely without losing any performance. The recovery and reuse of scrap copper are key components of the modern copper industry, significantly reducing energy consumption and mining demands, reflecting the principles of sustainable development.

Types and Alloys of Copper

Copper types are numerous, typically classified based on their purity and main alloying elements to meet specific performance and application needs.

| Alloy Category | Main Alloying Element | Summary of Characteristics | Typical Applications (Related to Machining) |

|---|---|---|---|

| Pure Copper | None (>99.9% Cu) | Highest electrical/thermal conductivity; excellent ductility. | Electrodes, busbars, high-thermal conductivity heatsink components. |

| Brass | Zinc (Zn) | Higher strength; excellent machinability; good castability. | Valves, pipe fittings, gears, precision instrument components. |

| Bronze | Tin (Sn), Aluminum (Al), etc. | High strength; wear-resistant, corrosion-resistant; tin bronze, in particular, has good elasticity. | Bearings, bushings, propellers, heavy-duty structural parts. |

| Cupronickel | Nickel (Ni) | Excellent resistance to seawater corrosion; antimicrobial, aesthetically pleasing color (silver-white). | Marine engineering components, heat exchangers, pumps, and valves. |

| Special Copper Alloys | Beryllium (Be), Chromium (Cr), etc. | High strength, high elasticity, high hardness; Beryllium copper provides the highest strength and hardness. | Molds, precision springs, high-pressure connectors, aerospace. |

Machining Characteristics and Tips:

For a precision machining service station, the choice of copper alloy directly affects processing efficiency and finished product quality:

Properties of Copper

Physical Properties

- Density: Approximately 8.96 g/cm³ (higher than steel and aluminum).

- Melting Point: 1083 °C.

- Electrical Conductivity: Can exceed 100% of the International Annealed Copper Standard (IACS), making it the preferred choice for power transmission.

- Thermal Conductivity: Approximately 401 W/m·K (pure copper). Its extremely high thermal conductivity makes it a core material for thermal management systems.

Mechanical Properties

- Tensile Strength: Varies widely, from approximately 200 MPa for pure copper to over 1000 MPa for beryllium copper alloys.

- Ductility: Excellent; the elongation of pure copper is usually higher than 40%.

- Fatigue Performance: Copper alloys have good fatigue resistance, making them suitable for components subjected to cyclic loads.

Special Properties

- Corrosion Resistance: Copper exhibits excellent corrosion resistance in fresh water, seawater, non-oxidizing acids, and the atmosphere.

- Antimicrobial Properties: Copper surfaces have a natural antimicrobial effect, effectively killing bacteria, viruses, and fungi, giving them unique value in medical, public health, and architectural fields.

Advantages and Limitations

| Advantages | Limitations |

|---|---|

| Excellent electrical and thermal conductivity, irreplaceable. | Relatively high cost, especially compared to aluminum and ordinary steel. |

| Superior ductility and formability, easy for plastic working and cold processing. | Lower strength and hardness (pure copper), not suitable for heavy-duty applications requiring extremely high wear resistance and load-bearing capacity. |

| Outstanding corrosion resistance, especially in marine and humid environments. | Some high-strength copper alloys (such as beryllium copper) require specific processes and tools for machining, making cutting more challenging. |

| Natural antimicrobial properties, suitable for medical and public contact areas. | Easily reacts with certain chemicals (such as ammonia and sulfides). |

| Infinitely recyclable, environmentally friendly. |

Applications of Copper

Copper applications span almost all major industries, serving as the foundation for the functioning of modern society.

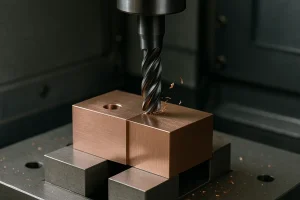

A selection of high-tolerance copper alloy components custom-machined by MinHe, essential for applications in New Energy, Electronics, and Thermal Management.

- Electrical and Electronics:

- Wires and cables, busbars, high-voltage switches, transformer windings.

- Printed Circuit Boards (PCB), chip packaging materials.

- Heat Exchange and Piping Systems:

- Fins and pipes in air conditioners, refrigerators, and industrial heat exchangers.

- Automotive radiators, brake lines.

- Architecture and Decoration:

- Roofing, curtain walls, door handles, piping systems.

- Antimicrobial door handles and surfaces in medical equipment.

- Automotive and Transportation:

- Battery connectors and wiring harnesses in electric vehicles.

- Conductive and thermal components in aerospace.

MinHe’s processing capabilities

Our service station specializes in high-precision custom machining. Our capabilities for copper materials primarily cover: high-conductivity connectors, precision heatsinks, custom valve bodies and fittings, and high-precision gears and bushings in instrumentation. The copper components we provide are widely used in new energy, medical equipment, and high-end electronic products.

Conclusion

Copper, this ancient yet modern metal, forms the systemic framework from microelectronics to macroscopic industrial structures, thanks to its excellent conductivity, thermal properties, corrosion resistance, and machinability. It perfectly bridges historical significance and future technology.

In the global wave of electrification, digitalization, and sustainable development, the strategic value of copper will only continue to increase. For precision machining, mastering the processing characteristics of copper and its complex alloys is key to providing high-quality, high-performance custom services.

Your need for precision copper components is exactly where our professional strengths lie. Contact us for a machining quote or design consultation on complex alloys such as copper, brass, and bronze, and build your innovative projects on the most reliable metallic foundation.