In the field of precision manufacturing, we often encounter challenges that traditional cutting methods simply can’t handle. The need to machine extremely hard materials, create complex internal structures, and meet strict demands for high precision has called for a new kind of manufacturing technology. To solve these very problems, Electrical Discharge Machining (EDM) was born. This is a non-traditional, advanced manufacturing process that uses precisely controlled electrical sparks to remove material, achieving a level of precision that is impossible with conventional mechanical machining. In this article, we’ll take a deep dive into the working principles of Electrical Discharge Machining, its main types, as well as its unique advantages and broad applications in modern industry.

What is Electrical Discharge Machining?

Electrical Discharge Machining is a non-traditional process that uses precisely controlled electrical sparks to remove material. It relies on powerful electrical energy instead of mechanical force, achieving an incredible level of precision without making contact with the workpiece. This technology has completely transformed how hard materials and complex parts are manufactured.

How Electrical Discharge Machining Works

The secret to Electrical Discharge Machining lies in a meticulously controlled physical process. This process removes material through a series of precise steps using electrical energy:

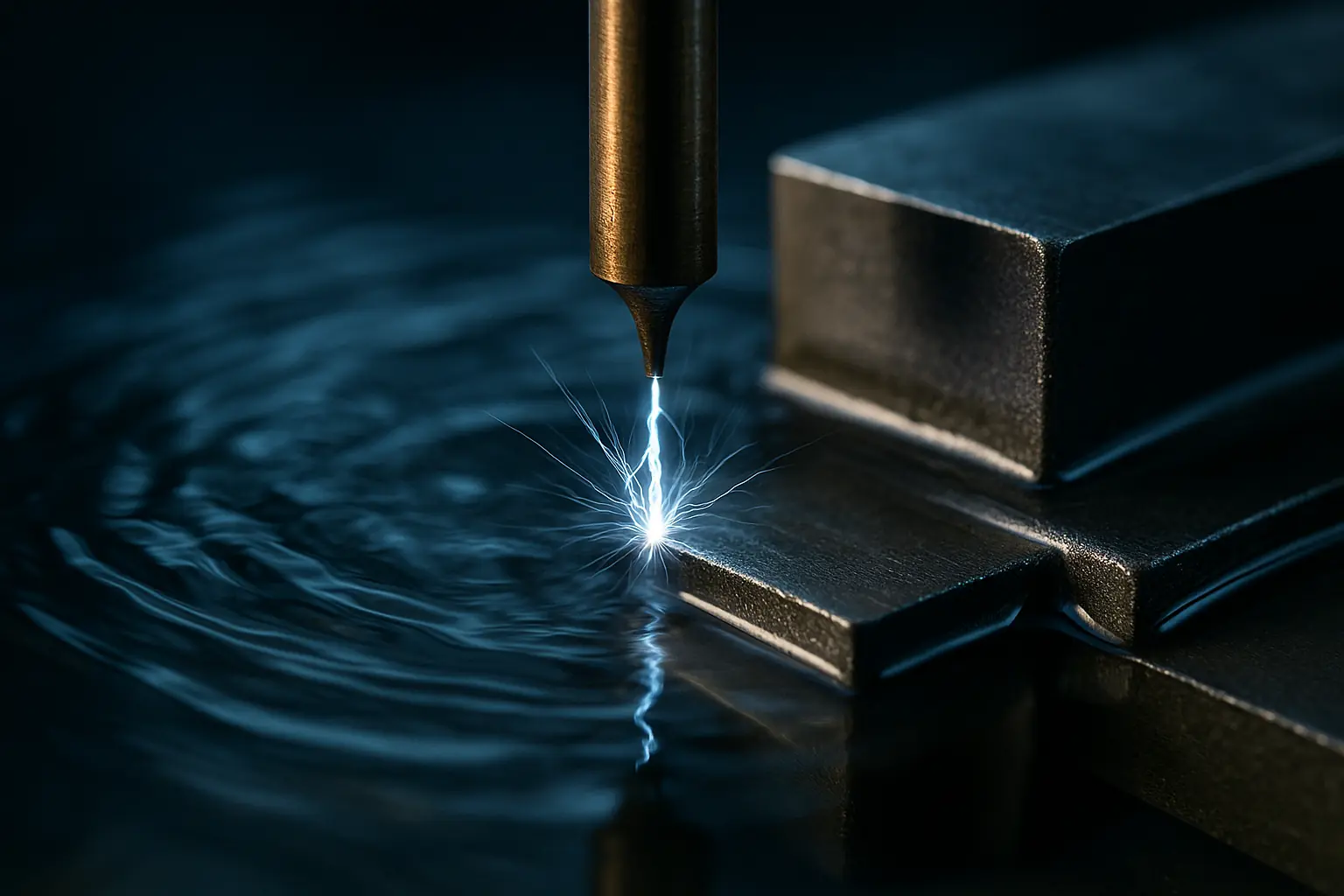

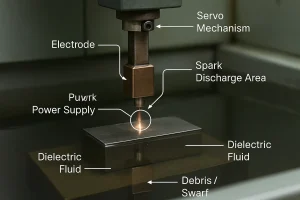

- Preparation Phase: First, the workpiece and electrode are submerged in a dielectric fluid, such as deionized water or oil. This fluid acts as an insulator before discharge and helps to cool the workpiece and flush away molten material during the process.

- Discharge Phase: When the machine applies a high-frequency pulse voltage and the gap between the electrode and the workpiece is sufficiently small, the dielectric fluid ionizes, instantly forming a tiny plasma channel between the two.

- Material Removal: This plasma channel generates an intense electrical spark at thousands of degrees. The powerful energy is enough to melt and vaporize a microscopic portion of the material from the workpiece’s surface.

- Cooling and Flushing: After the spark extinguishes, the melted material quickly solidifies into tiny spherical particles, which are then flushed away by the dielectric fluid. This process repeats hundreds of thousands of times per second, precisely carving out the desired shape.

The essence of this process is non-contact machining, which avoids mechanical stress and tool wear, allowing it to handle ultra-hard materials that are impossible to cut with traditional methods.

The History of Electrical Discharge Machining

The principle of Electrical Discharge Machining (EDM) was first discovered in 1770 by the British physicist Joseph Priestley. However, it wasn’t until nearly two centuries later that the technology was applied to manufacturing. In the 1940s, Soviet scientists B. and N. Lazarenko, while studying electrode wear, unexpectedly found that electrical discharges could be used to precisely remove material. They went on to invent the first practical EDM machine, laying the foundation for the technology’s industrial use. With the rise of Computer Numerical Control (CNC), EDM made significant strides in accuracy and automation, becoming an indispensable part of modern precision manufacturing.

Main Types of Electrical Discharge Machining

Based on the principles above, Electrical Discharge Machining has evolved into several main types, with each serving a specific machining need based on its working method and tooling.

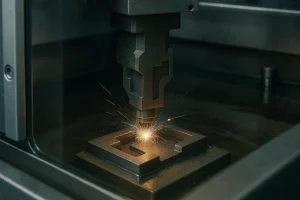

Wire Electrical Discharge Machining

This type of Electrical Discharge Machining uses a continuously moving, extremely thin metal wire (typically brass) as the electrode, guided by a sophisticated CNC system. The wire acts like a precise saw, accurately cutting intricate two-dimensional contours in the workpiece. Wire Electrical Discharge Machining is especially good at making stamping dies, jigs, and other precision parts with complex internal corners and sharp angles.

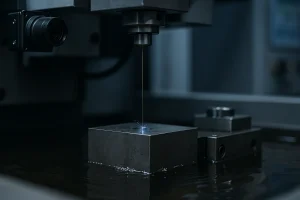

Die Sinking Electrical Discharge Machining

Also known as Ram EDM, this method uses a pre-machined electrode with a specific shape. As the electrode is fed toward the workpiece under CNC control, the discharge sparks continuously erode the workpiece, accurately “forming” the electrode’s shape into the part. This is much like a sculptor using a tool to leave an impression in stone. Die Sinking Electrical Discharge Machining is the ideal choice for creating complex three-dimensional shapes, deep grooves, and intricate mold cavities.

Hole Drilling Electrical Discharge Machining

As its name suggests, this Electrical Discharge Machining process is dedicated to quickly and efficiently drilling small, deep holes in metal workpieces. It uses a rapidly rotating tubular electrode and can easily create straight, precise holes in hard-to-machine materials. This technology is often used to create starter holes for Wire Electrical Discharge Machining or to machine intricate cooling holes in aircraft engine turbine blades.

Materials for Electrical Discharge Machining

Electrical Discharge Machining can easily process a wide range of hard and high-strength materials. However, since its working principle relies on electrical energy, the process is limited to machining electrically conductive materials.

Materials That Can Be Machined

-

Various Steels: Tool steel, mold steel, stainless steel, hardened steel, etc.

-

High-Strength Alloys: Nickel alloys, cobalt alloys, titanium alloys, superalloys, etc.

-

Non-Ferrous Metals: Brass, copper, aluminum, cemented carbide, etc.

-

Special Materials: Graphite, certain conductive ceramics, composite materials, magnetic materials, etc.

Materials That Cannot Be Machined

-

Most plastics, glass, fibers, and non-conductive ceramics, etc.

Advantages of Electrical Discharge Machining

The unique advantages of Electrical Discharge Machining have made it an indispensable technology in several high-tech industries.

- High Precision and Excellent Surface Finish: As a non-contact process, Electrical Discharge Machining can achieve extremely high dimensional accuracy and create intricate internal features and sharp corners that would be impossible with traditional methods. This process also yields a superior surface finish, especially on hard materials.

- Ability to Machine Hard Materials: Electrical Discharge Machining can easily process materials like hardened steel, tungsten carbide, and titanium alloys that are impossible to handle with traditional cutting methods. Since the entire process is non-contact, it doesn’t create mechanical stress, which prevents workpiece deformation and tool wear, ensuring stable and consistent machining.

- Complex Shapes: The non-contact nature of the process allows for the creation of intricate internal features and sharp corners that are not possible with traditional methods.

Disadvantages of Electrical Discharge Machining

- Slow Machining Speed: Compared to traditional milling or turning, EDM is a very slow process, especially when a large volume of material needs to be removed.

- High Energy Consumption: The EDM process requires a significant amount of electrical energy, which directly increases production costs.

- Material Limitations: Due to its reliance on electrical discharges, this process is limited to machining electrically conductive materials and cannot be used on non-conductive materials like ceramics or plastics.

- Surface Quality Issues: EDM can leave a “recast layer” on the workpiece surface, which is a layer of melted and re-solidified material. This can affect the physical properties of the material and may require additional post-processing to remove or improve the surface quality.

Applications of Electrical Discharge Machining

- Mold and Tool Making:Electrical Discharge Machining is widely used to manufacture precision injection molds, die-casting molds, and stamping dies, ensuring the quality and consistency of the final product.

- Aerospace:In aircraft engine manufacturing, Electrical Discharge Machining is used to create tiny cooling holes in turbine blades. The precision of these holes directly impacts the engine’s performance and lifespan.

- Medical Devices:This process is used to produce miniature, high-precision surgical tools and orthopedic implants, such as titanium bone screws. Its high precision and stress-free machining characteristics are critical for product safety.

Conclusion

Electrical Discharge Machining is more than just a manufacturing method; it’s a cornerstone of modern precision manufacturing. By precisely controlling electrical energy, it surpasses traditional processes, allowing for the machining of the hardest materials, the creation of the most complex shapes, and the delivery of unparalleled accuracy and consistency. As technology continues to evolve, Electrical Discharge Machining will play an even more central role in future industrial innovation, helping us turn more designs into reality.

If you have any questions about this powerful technology or want to discuss how it can benefit your projects, feel free to contact us.