Electroplating is one of the most common and effective surface finishing methods used after CNC machining. By depositing a thin metallic layer on a part’s surface, engineers can significantly improve its corrosion resistance, wear resistance, conductivity, and appearance. Compared with anodizing, passivation, or painting, electroplating forms a more functional and precisely controlled metallic coating. It plays a vital role in achieving both performance and aesthetic quality in industries such as automotive, aerospace, mold making, and precision engineering. The following sections explain what electroplating is, when to use it, how it works, its main types, suitable materials, and key applications.

What Is Electroplating

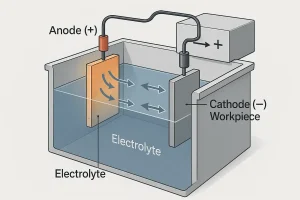

Electroplating is a controlled electrochemical process in which metal ions in an electrolyte solution are reduced onto the surface of a conductive workpiece under an external electric current. In a typical setup, the workpiece acts as the cathode and the plating metal as the anode, both immersed in a metal salt solution. When current passes through, metal ions migrate toward the cathode and form a dense metallic coating.

Illustration of the electroplating setup, showing the anode, cathode, electrolyte bath, and electric current direction.

This is why it is called “electroplating”: “electro” refers to the use of electrical energy to drive the chemical reaction, while “plating” refers to the deposition of a metal layer on the surface. The resulting coating enhances hardness, conductivity, and corrosion resistance while improving the overall appearance of the component.

When to Use Electroplating

Electroplating is used when machined parts need enhanced performance in corrosion resistance, wear resistance, or electrical properties. It is usually performed after all machining and polishing steps are completed, as the final surface treatment before assembly.

Common use cases include:

- Corrosion protection: Nickel or zinc plating on steel and iron parts to prevent rust and oxidation.

- Wear resistance: Hard chromium plating on shafts, molds, and piston rods to increase surface hardness.

- Electrical improvement: Tin, silver, or gold plating on copper and brass components to enhance conductivity and solderability.

- Decorative finish: Bright nickel or chrome plating on stainless steel and aluminum parts for a reflective metallic appearance.

Electroplating is ideal for components operating in humid, corrosive, or high-friction environments, providing durable protection and a refined visual finish without affecting dimensional precision.

How to Perform Electroplating

The electroplating process generally includes three stages: pre-treatment, electro-deposition, and post-treatment. Each stage directly affects coating adhesion, surface quality, and long-term durability.

Pre-treatment

Before plating, the part must be thoroughly cleaned and activated. This includes degreasing, acid pickling, and oxide removal. Any remaining oil or oxide film can cause blistering or peeling. Proper pre-treatment ensures strong adhesion and uniform deposition of metal ions.

Electro-deposition

This is the core stage of electroplating. By controlling voltage, current density, temperature, and time, metal ions are evenly deposited on the workpiece surface.

Typical process parameters vary: nickel plating often operates at 45 °C and 1–6 A/dm², while chromium plating requires higher voltage and lower current efficiency.

Coating thickness typically ranges from 5–50 µm, determining both the mechanical performance and the surface appearance.

Post-treatment

After plating, the workpiece undergoes rinsing, neutralization, drying, and sometimes polishing or sealing. The coating is then tested for thickness, adhesion, gloss, and corrosion resistance. Post-treatment ensures uniform appearance and long-term stability of the coating.

Main Types of Electroplating

Electroplating technologies can be categorized into several major types based on the current form, chemical mechanism, and part-handling method.

Each approach offers different advantages in coating quality, process cost, and suitability for specific component geometries.

1. Conventional DC Plating

The most widely used electroplating process, DC plating applies a constant current to deposit metal ions on the surface.

It offers stable control of coating thickness, simple equipment, and low cost, making it suitable for most conductive materials.

However, uneven current distribution can occur on complex geometries, leading to over-thick edges or thin inner corners.

Typical applications: Nickel, chrome, or zinc plating of shafts, bolts, and decorative parts.

2. Pulse and Reverse-Pulse Plating

This method alternates current pulses or reverses polarity to refine the grain structure, relieve stress, and improve adhesion.

It produces denser, smoother, and brighter coatings than conventional DC plating, ideal for high-precision parts with strict surface requirements.

The downside is higher equipment cost and more complex process control.

Typical applications: Mold cavities, electronic connectors, and high-gloss precision components.

3. Electroless (Chemical) Plating

Electroless plating relies on a chemical reduction reaction rather than external current.

Its greatest advantage is exceptional coating uniformity—even in blind holes, threads, and internal cavities.

Nickel-based electroless plating (Ni–P or Ni–B) is widely used as both a functional and a base layer.

Process control is complex, as bath composition and temperature must be precisely maintained.

Typical applications: Aluminum housings, precision valve bodies, plastic substrates, and aerospace components.

4. Mechanical and Specialized Plating Methods

These include barrel plating, rack plating, and brush plating:

- Barrel plating: Small parts tumble in a rotating drum immersed in electrolyte; low-cost and efficient for mass production.

- Rack plating: Parts are fixed on conductive racks for uniform coating, ideal for large or appearance-critical parts.

- Brush plating: A portable anode tool applies coating directly for localized repair or rework.

Each method balances efficiency, quality, and cost differently.

Typical applications: Fasteners (barrel plating), decorative housings (rack plating), and tool repair (brush plating).

Materials Suitable for Electroplating

Visual comparison of common electroplating finishes such as nickel-plated, chrome-plated, and zinc-coated parts used in precision manufacturing.

Different base materials require specific surface preparation to ensure adhesion. The table below summarizes typical machinable materials, plating compatibility, and key process notes.

| Material | Plating Compatibility | Recommended Coating / Process | Notes |

|---|---|---|---|

| Carbon and alloy steel | Excellent | Nickel, chrome, zinc | Ensure full cleaning; avoid hydrogen embrittlement |

| Stainless steel | Good | Nickel, gold | Acid activation required to remove passive film |

| Copper and brass | Excellent | Tin, silver, gold | High conductivity; ideal for functional plating |

| Aluminum and alloys | Moderate | Electroless nickel base + nickel/chrome top | Chemical base layer improves adhesion |

| Titanium, magnesium, plastics | Difficult | Electroless nickel or precious metals | Require conductive pre-treatment; higher cost |

Advantages of Electroplating

- Greatly improves corrosion resistance (salt spray > 300 h)

- Surface hardness up to HV 800 or higher

- Enhances conductivity, lubricity, and solderability

- Provides bright or matte decorative finishes

- Mature process, cost-effective, suitable for mass production

Limitations and Considerations

- Uneven thickness on complex geometries

- Electrolyte waste requires environmental treatment

- Multi-layer plating increases process time and cost

- Poor pre-treatment may cause blistering or peeling

- Strict inspection needed for thickness and adhesion uniformity

Typical Applications

- Machinery and molds: Hard chrome plating for wear-resistant tool surfaces

- Automotive: Zinc or nickel coatings for shafts, bolts, and hydraulic rods

- Electronics: Gold or tin plating for improved conductivity and oxidation resistance

- Aerospace and medical: Composite coatings for corrosion protection and aesthetics

Conclusion

Electroplating remains a key post-machining process that combines both functional and decorative performance.

By selecting the right coating metal and plating method, manufacturers can achieve the desired balance of cost, durability, and appearance for precision components.

Request a quote from our engineering team or upload your drawings for a fast electroplating review and quotation.