Aluminum is one of the most widely used materials in CNC machining, precision manufacturing, and lightweight engineering. Its popularity comes from a unique combination of low density, high strength-to-weight ratio, corrosion resistance, and excellent machinability. Whether designing structural frames, robotic components, aerospace brackets, electronic housings, or automotive parts, understanding aluminum density is fundamental for accurate weight estimation, performance prediction, and cost planning.

This guide offers a clear understanding of aluminum density across commonly used alloys and explains how these values influence part weight, stiffness, machining stock estimation, and overall design performance. It also includes detailed alloy charts and practical weight calculation methods for CNC engineers.

What Is the Density of Aluminum?

The density of a material is defined as mass per unit volume (ρ = m/V). For aluminum, the standard density values are:

- 2.70 g/cm³

- 2700 kg/m³

- 0.0975 lb/in³

This density is roughly one-third that of steel and copper. Because of this, substituting aluminum for heavier metals can drastically reduce weight while maintaining sufficient structural integrity, making aluminum an essential material in aerospace, automotive, electronics, and industrial automation.

Factors That Affect Aluminum Density

Although “2.70 g/cm³” is commonly cited, aluminum alloys exhibit small but meaningful variations in density due to composition and manufacturing processes. Understanding why density changes helps engineers select the correct alloy for weight-sensitive applications.

Alloying Elements

Different alloying elements have different densities, causing shifts in the weight of the final alloy.

- Magnesium (Mg) and Silicon (Si) are lighter than aluminum.

Alloys rich in Mg or Si—such as 5052, 5083, and 6063—tend to have slightly lower density. - Copper (Cu) and Zinc (Zn) are heavier.

High-strength aerospace alloys like 2024, 7075, and 7050 have higher density because of their high Cu or Zn content.

In practical engineering, this means:

5083 may be one of the lightest commonly used structural alloys,

while 7075 and 7050 sit at the heavier end of the aluminum family.

Manufacturing Process

Density is also influenced by how the material is produced:

- Wrought aluminum (extruded, rolled, forged) has a dense, uniform microstructure.

Its density is consistent and matches theoretical values closely. - Cast aluminum can contain micro-porosity or larger grain structures.

As a result, cast alloys like A380, A356, and ADC12 may show slight deviations between theoretical and measured density.

This difference is important when calculating stock weight for CNC machining after casting.

Heat Treatment

Heat treatments such as T6, T651, or T73 affect strength and hardness but have negligible effect on density.

For weight calculations, engineers can assume all temper conditions of the same alloy share the same density.

Density of Common Aluminum Alloys

In practical engineering, aluminum alloys are typically grouped into wrought alloys and casting alloys, as these two categories cover nearly all applications from CNC machining to structural and enclosure parts. The tables below summarize the density values of the most widely used grades across global manufacturing.

Wrought Aluminum Alloys

Wrought alloys are used for sheet, plate, bar stock, and extrusions—forming the bulk of CNC machining materials. These alloys offer consistent density and predictable mechanical behavior.

| Alloy | Density (g/cm³) | Notes |

|---|---|---|

| 1050 | 2.70 | Commercially pure aluminum; soft but ductile |

| 3003 | 2.73 | General-purpose sheet, moderate strength |

| 5052 | 2.68 | Marine grade; good formability and corrosion resistance |

| 5083 | 2.66 | High toughness; among the lighter structural alloys |

| 6061-T6/T651 | 2.70 | Most versatile CNC machining alloy |

| 6063 | 2.69 | Extrusions, heat sinks, architectural profiles |

| 6082 | 2.70 | Structural frames; common in EU markets |

| 2024 | 2.78 | High fatigue strength; aerospace |

| 7075-T6 | 2.81 | Highest strength aluminum; increased density |

Wrought aluminum alloys cover the majority of structural and functional CNC parts, including brackets, enclosures, robotic arms, frames, and precision fixtures.

Cast Aluminum Alloys

Cast aluminum is used when complex shapes or large volumes are required. The cast parts are often machined afterward to achieve precise tolerances and sealing surfaces.

| Alloy | Density (g/cm³) | Common Use |

|---|---|---|

| A356 | 2.68 | Gravity-cast housings, wheels, structural castings |

| A380 | 2.71 | Die-cast motor housings, gearbox covers |

| ADC12 | 2.74 | Thin-wall and intricate die-cast parts |

| ZL101 | 2.68 | General-purpose casting alloy |

| MIC-6 | 2.79 | Precision cast tooling plate used for CNC fixtures |

Cast alloys are crucial when machining is combined with upstream die casting or gravity casting.

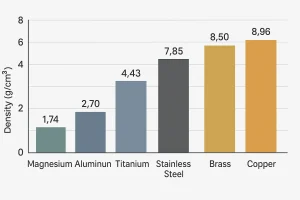

Density Comparison with Other Metals

Comparing aluminum with other metals underscores why it dominates lightweight structural design. The table below shows common engineering materials.

| Material | Density (g/cm³) | Relative to Aluminum |

|---|---|---|

| Aluminum | 2.70 | 1.0× |

| Magnesium Alloy | 1.74 | 0.64× |

| Titanium Alloy | 4.43 | 1.64× |

| Stainless Steel | 7.85 | 2.9× |

| Brass | 8.50 | 3.15× |

| Copper | 8.96 | 3.32× |

This highlights why aluminum is preferred when weight reduction is essential but magnesium or titanium are not viable due to cost or mechanical constraints.

Engineering Impact of Aluminum Density

Aluminum’s density directly dictates how a component behaves under real-world engineering conditions. It affects structural rigidity, dynamic response, fatigue behavior, motor load, thermal efficiency, and even total manufacturing cost. Understanding these relationships enables better material selection and more accurate design decisions for CNC projects.

Weight and Structural Optimization

Reducing component weight is crucial in systems that involve motion, payload limits, or energy consumption. Aluminum’s low density allows engineers to reduce mass without sacrificing strength. Furthermore, because stiffness increases with thickness³, designers can increase section size to improve rigidity while still maintaining low overall weight.

This makes 6061, 6082, and 5052 popular choices for frames, machine bases, fixtures, and outer housings.

Dynamic Performance and Inertia

In moving systems, mass determines inertia. Lower density reduces the force required for acceleration and deceleration (F = ma). This is particularly important in:

- robotic end-effectors

- high-speed linear modules

- precision motion stages

- lightweight automated tooling

By minimizing inertia, aluminum components can improve cycle time, reduce motor load, and enhance responsiveness.

Strength-to-Weight Ratio and Stiffness Efficiency

High-strength alloys like 7075 and 2024 provide exceptional strength while remaining far lighter than steel. This combination enables aerospace-style optimization where components must be as strong as possible but remain lightweight.

In CNC machining, this allows:

- lightweight yet stiff brackets

- rigid frames that resist bending under load

- high-performance parts for UAVs and performance vehicles

Material Cost and Machining Stock Estimation

Because raw material is priced by weight, density directly affects procurement cost. Higher-density alloys result in heavier stock, influencing:

- BOM cost

- machining time (via material removal volume)

- shipping and logistics cost

Accurate density data improves quoting accuracy for both prototypes and mass production.

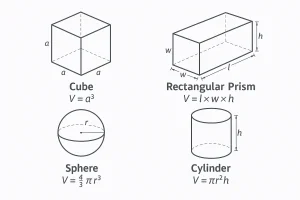

How to Calculate the Weight of Aluminum Parts

Accurate weight calculation is an essential step in design, cost estimation, and CNC machining planning. By knowing the density of the selected alloy, engineers can evaluate raw material requirements, assess structural loads, and estimate shipping or logistics costs. The basic formula for calculating weight is:

Weight (kg) = Volume (cm³) × Density (g/cm³) ÷ 1000

The following examples show how this formula is applied in common machining scenarios.

Aluminum Plate (Fixture Base)

- Material: 6061

- Size: 500 × 300 × 20 mm

- Volume: 3000 cm³

- Weight: 8.1 kg

This method is typically used for base plates, tooling blocks, and rectangular CNC stock.

Aluminum Round Bar (Turning Stock)

- Material: 7075

- Size: Ø50 mm × 200 mm

- Weight: ≈ 1.10 kg

Useful for estimating raw material for lathe operations or turned components.

Complex Extrusions

For irregular extrusion profiles, weight is calculated using:

Weight = Cross-sectional area (from CAD) × Length × Density

Alternatively, suppliers often provide kg/m specifications for each extrusion model.

These calculations help determine machining allowance, material procurement quantities, and expected final part mass, supporting more accurate quoting and production planning.

Applications Where Density Is Critical

Aluminum is used broadly across manufacturing, but certain applications depend on its low density more than others. In these scenarios, reducing mass directly improves payload capacity, energy efficiency, acceleration response, or structural behavior under dynamic load. Aluminum’s density is therefore not just a material property—it becomes an essential design parameter.

Aerospace Structures

Aircraft ribs, brackets, frames, and interior structural components rely on aluminum to keep overall mass within strict limits. Alloys such as 2024 and 7075 offer high strength while keeping weight low enough to maintain fuel efficiency and thrust-to-weight performance.

Electric Vehicle Battery Trays and Housings

Vehicle range is heavily affected by total mass. Using aluminum for battery enclosures and underbody trays reduces structural weight while providing sufficient stiffness, corrosion resistance, and thermal conduction for heat management.

Robotic End-Effectors and Motion Assemblies

In high-speed automation, reducing inertia is essential for fast acceleration and precise control. Aluminum tools, adapter plates, and brackets help lower moving mass, reduce servo motor load, and improve cycle time in robotic systems.

Heat Sinks and Thermal Components

Thermal modules in power electronics and communication equipment frequently use aluminum because it offers strong heat dissipation at one-third the weight of copper. This prevents excessive mass on PCBs or housings while maintaining reliable thermal performance.

Conclusion

Most aluminum alloys fall within a density range of 2.66–2.83 g/cm³, with small variations caused by different alloying elements and manufacturing routes. Although these differences may appear minor, they significantly affect part weight, machining stock requirements, structural stiffness, and the dynamic response of moving assemblies.

A solid understanding of aluminum density allows engineers to make better material choices, estimate machining stock more accurately, and optimize designs for lightweight performance. This becomes especially important in sectors where payload, energy consumption, or motion efficiency are critical.

If you require CNC machining for 6061, 7075, 5052, 5083, A380, ADC12, MIC-6, or any other aluminum alloy, you are welcome to upload your CAD files. Our engineering team will provide a detailed evaluation and a fast production quote.