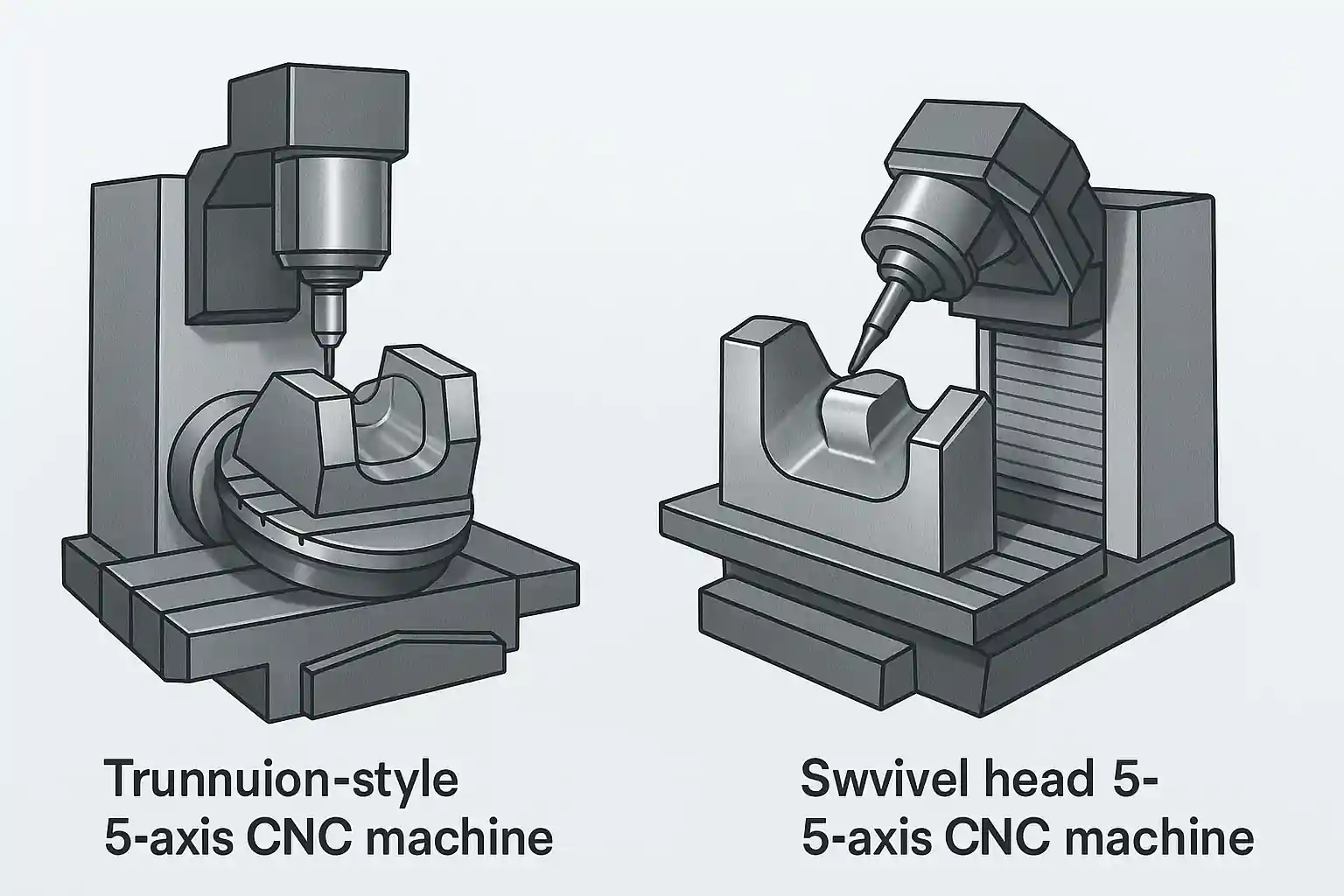

Trunnion vs. Swivel Head: Two Distinct 5-Axis Designs

When evaluating 5-axis CNC machines, the most fundamental distinction lies in their mechanical design. Most fall into two categories: trunnion-style and swivel head configurations. Each design offers unique benefits—and potential limitations—depending on the size, shape, and complexity of the parts you’re machining.

Trunnion-Style 5-Axis Machines: Compact Power for Complex Parts

Trunnion-style 5-axis machines incorporate a rotating and tilting table—often called an A/C-axis rotary table—mounted on a 3-axis machining center. The part is fixed to the table, which tilts and rotates to achieve simultaneous multi-axis movement while the cutting tool remains stationary in orientation.

Trunnion-style machines provide a rigid platform for complex part positioning and simultaneous 5-axis machining.

This architecture provides excellent rigidity and mechanical leverage, making it well-suited for aggressive material removal and high-speed contouring. Since the spindle orientation doesn’t change, tool paths can be more predictable, and tool life can often be extended. The rigid connection between tool and part allows for tighter tolerances, particularly on contoured surfaces, thin walls, or fine-featured mold cavities.

Trunnion setups also benefit from superior chip evacuation due to part rotation, which can reduce tool loading and improve surface finish. These machines are a staple in aerospace, medical, and moldmaking industries—anywhere complex geometry meets demanding tolerances.

However, there are limitations. As the trunnion table tilts, the available machining envelope shrinks, especially in the Z-axis. This can restrict the size or orientation of larger parts. Fixturing becomes more complex for awkward geometries, and parts may require custom fixtures or clamps to avoid collisions during tilt-rotate motions.

For shops machining small to medium-sized parts with high accuracy demands, the trunnion-style platform offers an excellent balance of performance and footprint efficiency.

Swivel Head Designs: Greater Flexibility and Tool Access

Swivel head (or articulating head) 5-axis machines achieve multi-axis movement by rotating the cutting spindle itself, rather than tilting the part. Typically, the head pivots around the A and B axes, allowing the tool to approach the workpiece from virtually any angle. The part remains fixed on a stationary table, simplifying fixture design and maximizing usable work volume.

This design excels in machining tall or heavy components—especially when rotating such parts is impractical or unsafe. Because the workpiece doesn’t move, there’s less risk of clearance issues, part deformation, or dynamic imbalance. Large aerospace structures, engine housings, and welded assemblies often benefit from this architecture.

Swivel head machines also provide excellent access to deep cavities, undercuts, and complex 3D surfaces. When combined with extended toolholders or long end mills, they allow the tool to “reach in” without needing the part to tilt or shift. This is especially useful in industries like energy, automotive, and die/mold where internal features are critical.

That said, moving-head designs typically sacrifice a small degree of rigidity compared to fixed-spindle systems—especially during heavy cuts or long-reach operations. Dynamic forces from the tool rotation can introduce deflection or vibration, which must be managed through toolpath strategy, feed rate optimization, or support tooling.

For applications that require maximum flexibility across a broad part range, or where workholding constraints limit part movement, swivel head machines offer unmatched adaptability.

Comparing Trunnion and Swivel Head Systems

Side-by-side visual comparison of trunnion-style and swivel-head 5-axis CNC machine configurations.

| Feature | Trunnion-Style | Swivel Head |

|---|---|---|

| Part Movement | Rotates/tilts on table | Stationary part |

| Spindle Rigidity | High (fixed head) | Moderate (moving head) |

| Ideal for | Small to medium precision parts | Large or tall/heavy parts |

| Fixture Complexity | Moderate to high | Simple |

| Deep Cavity Access | Limited | Excellent |

| Setup Flexibility | Lower | Higher |

| Machine Footprint | Compact | Typically larger |

Choosing the Right Configuration for Your Workflow

If your operations center on compact parts that demand high-speed machining and consistent dimensional accuracy, a trunnion-style setup offers excellent results. Swivel head machines, on the other hand, handle larger, heavier, or geometrically complex parts more efficiently.

Your decision should align with the dominant part types you process, as well as the floor space and fixture strategies available in your shop.

Summary and Practical Considerations

Trunnion machines provide superior rigidity and efficiency for smaller parts, while swivel head systems shine when flexibility and reach are required. Many modern shops choose one based on production needs—or invest in both for broader capability.

Not sure what fits your workflow? Reach out to our team for expert guidance in selecting the right 5-axis solution.

For a complete overview of 5-axis machining technology, including its principles, benefits, and common applications, we recommend reading our ultimate 5-axis machining guide.