What Manufacturers Should Know Before Outsourcing 5-Axis CNC Machining

When faced with complex geometries, tight tolerances, or urgent project timelines, manufacturers frequently turn to professional 5-axis CNC machining services. Rather than simply being an additional manufacturing option, these services can significantly elevate product quality, reduce production time, and ensure competitiveness in demanding industries. This article explores what you should expect from outsourcing 5-axis CNC machining, covering core capabilities, industry applications, benefits, and critical cost factors.

Core Capabilities of Professional 5-Axis CNC Machining Services

5-axis CNC machining goes beyond traditional 3-axis processes by adding simultaneous multi-axis movements, enabling unprecedented manufacturing flexibility and precision. Key capabilities include:

- Complex Geometry Machining: With simultaneous 5-axis interpolation, intricate designs and complex shapes can be created in fewer setups, significantly reducing production time and enhancing part accuracy.

- High Precision and Tighter Tolerances: These advanced machining processes routinely achieve tolerances as precise as ±0.001 inches (±0.025 mm), essential for industries like aerospace, medical device manufacturing, and precision tooling.

- Superior Surface Finish: Smooth and continuous multi-axis toolpaths result in exceptional surface quality, greatly reducing or even eliminating the need for secondary finishing operations.

- Integrated Multi-Operation Capability: Milling, drilling, threading, and other operations can be integrated into a single setup, streamlining workflow, minimizing handling errors, and maximizing throughput.

Real-World Applications Across Industries

Professional 5-axis machining services are utilized extensively across high-demand industries. Examples of real-world applications include:

- Aerospace: Precision-machined turbine blades, impellers, and structural aircraft components.

- Medical Devices: Surgical instruments, orthopedic implants, and dental prosthetics that require intricate geometries and high precision.

- Tooling and Mold Making: Complex injection molds and precision die-casting dies produced with remarkable accuracy.

- Energy Sector: Critical components such as turbine housings, valve bodies, and advanced pump components requiring tight tolerances and reliability.

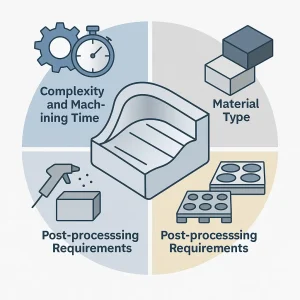

Visual breakdown of key cost drivers in 5-axis CNC machining, such as complexity, material choice, and production volume.

Strategic Benefits of Outsourcing 5-Axis CNC Machining

Deciding between in-house production and outsourcing 5-axis CNC machining services can significantly impact your project’s success and profitability. Outsourcing to experienced providers offers several strategic advantages, making it an increasingly popular choice:

- Cost Efficiency: Eliminate substantial upfront capital investments associated with acquiring high-end machining equipment and avoid continuous maintenance expenses. Outsourcing shifts these costs onto specialized providers, allowing your business to focus resources elsewhere.

- Scalability and Flexibility: Easily adjust production capacity based on project demands without worrying about idle equipment or workforce fluctuations. Professional machining service providers can readily accommodate changes in your production volumes.

- Access to Specialized Expertise: Leverage the skills of highly trained engineers and machinists who have extensive experience handling challenging and intricate 5-axis machining tasks. This ensures your projects benefit from industry-leading knowledge and best practices.

- Reduced Lead Times: Experienced service providers optimize manufacturing processes, employing advanced CAM software and optimized toolpath strategies to achieve faster turnaround times, helping you meet even the tightest deadlines.

Understanding the Cost Factors of 5-Axis Machining Services

While 5-axis CNC machining services offer numerous advantages, they come at a premium compared to traditional machining methods. To effectively manage your project’s budget, it’s essential to consider several influencing cost factors:

- Complexity of Parts and Machining Time: Intricate designs with tight tolerances or multi-faceted features naturally demand more machining time and meticulous setups, impacting overall cost.

- Choice of Materials: Hard-to-machine materials such as titanium, stainless steel, or hardened alloys typically incur higher machining and tooling expenses compared to more machinable materials like aluminum or engineering plastics.

- Production Volume and Order Frequency: Low-volume or prototype runs usually entail higher per-part costs due to setup overhead. Conversely, larger orders benefit from economies of scale, reducing per-unit costs significantly.

- Additional Processing Requirements: Post-processing services, including surface finishing, special coatings, or rigorous inspections, add incremental costs that must be factored into the total project budget.

This infographic illustrates how 5-axis CNC machining is applied in high-demand industries such as aerospace turbine blades, surgical implants, precision molds, and pump components—highlighting the process versatility and industry-specific use cases.

This infographic illustrates how 5-axis CNC machining is applied in high-demand industries such as aerospace turbine blades, surgical implants, precision molds, and pump components—highlighting the process versatility and industry-specific use cases.

Selecting the Right 5-Axis CNC Machining Provider

Choosing the appropriate machining partner goes beyond simply comparing quotes. Consider these crucial criteria to identify the best provider for your specific needs:

- Proven Industry Experience: Seek providers with demonstrated success in your target sectors, such as aerospace, medical, automotive, or mold making, ensuring adherence to industry-specific standards and requirements.

- State-of-the-Art Equipment: Confirm your chosen provider employs modern, well-maintained CNC machines and advanced software, guaranteeing reliable, high-precision outcomes.

- Rigorous Quality Control: Ensure your provider maintains strict quality assurance practices, backed by recognized certifications like ISO 9001 or AS9100, providing assurance of consistent quality and reliability.

- Effective Communication and Support: Select partners known for responsive communication, transparent project tracking, and robust technical support, facilitating seamless collaboration and addressing issues promptly.

Common Questions from First-Time Buyers

First-time users of 5-axis CNC machining services often have specific questions regarding the process:

How can I ensure my parts are optimized for 5-axis machining?

Engage with your service provider’s engineering team early in the design phase. They can help optimize your designs, improving manufacturability, precision, and cost-efficiency.

Is 5-axis CNC machining only cost-effective for large production runs?

No, small-scale production or even prototypes often benefit significantly from 5-axis capabilities due to reduced setups and improved accuracy, justifying the investment even at lower volumes.

What lead times should I realistically expect?

Typical lead times range from several days for prototype runs to a few weeks for more extensive or intricate production runs. Clearly communicating your timeline expectations early ensures accurate delivery schedules.

Ready to leverage the full potential of professional 5-axis CNC machining services? Contact our specialists today for expert guidance and receive a detailed, tailored quotation for your project.

Related Resources

If you’re exploring 5-axis solutions in depth, here are a few helpful guides:

For a complete overview of 5-axis machining technology, including its principles, benefits, and common applications, we recommend reading our ultimate 5-axis machining guide.