Understanding Compact 5-Axis CNC Machines

In modern manufacturing, 5-axis CNC machines have become increasingly accessible—not just for industrial factories, but also for smaller workshops. Among the most popular options are compact machines categorized as either small 5-axis CNC machines or desktop 5-axis CNC units. While both offer multi-axis capabilities in limited space, their construction, performance, and intended use vary significantly.

Understanding the functional differences between these two types is essential before making an investment, especially if you’re considering production demands, part sizes, and budget.

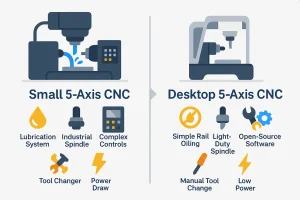

Visual guide comparing the size and configuration of small vs. desktop 5-axis CNC machines

Key Features of Small 5-Axis CNC Machines

Small 5-axis CNC machines are typically built for light industrial use. They feature rigid cast frames, higher spindle power, and larger work envelopes than desktop models. These machines often support tool changers, coolant systems, and professional-grade controllers, making them suitable for precise prototyping or low-volume production.

For workshops handling aluminum, steel, or composite materials, small 5-axis systems offer the balance of footprint and functionality. They’re also ideal for businesses looking to scale up from 3-axis setups without committing to a full-size machining center.

Who Should Choose a Desktop 5-Axis CNC Machine?

Desktop 5-axis CNC machines are ideal for makers, researchers, and startups who require compact, affordable, and precise milling capabilities. These machines shine in environments where space is limited and batch sizes are small—such as educational labs, jewelry prototyping, or electronics enclosures.

Despite their size, many desktop units support simultaneous 5-axis movement and run on advanced CAM software. They’re a solid entry point for learning complex toolpaths or producing micro-scale components. However, they may lack the rigidity and cutting force needed for heavy-duty metals or continuous use.

For hobbyists or R&D teams, a desktop 5-axis CNC is often more practical than investing in a larger industrial machine.

When a Small 5-Axis CNC Machine Makes More Sense

Small 5-axis CNC machines strike a balance between power and footprint. Unlike desktop models, these machines are built for light-to-medium production runs and are capable of handling tougher materials like aluminum or stainless steel with better rigidity and spindle performance.

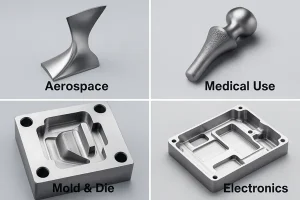

They’re often found in aerospace prototyping, dental labs, and high-precision machine shops. A small 5 axis CNC machine offers greater tool flexibility, larger work envelopes, and integrated automation options like tool changers or probing systems.

For workshops aiming to scale production while managing space constraints, this class of machine offers a reliable long-term investment without jumping straight to full industrial systems.

When a Desktop 5-Axis CNC Is the Better Choice

Desktop 5-axis CNC machines are ideal for education, research labs, and hobbyists. Their compact size and lower price point make them accessible for rapid prototyping and light-duty precision tasks. While they typically lack the rigidity and power of small industrial units, their portability and ease of use offer unique advantages.

A desktop 5 axis CNC machine is perfect for cutting plastics, wax, soft metals, and even circuit boards. They’re also a great choice for designers or engineers validating part geometries before committing to larger production runs.

However, buyers should be aware of limitations in spindle speed, cutting force, and work envelope. These systems are best suited for non-critical applications or early-stage development work.

For more on production-scale options, explore our guide to 5-axis CNC machine capabilities and services.

Comparing Maintenance and Operation Costs

Beyond the initial price tag, ongoing costs play a critical role in choosing between small and desktop 5-axis CNC machines. Small industrial machines may require more robust maintenance—such as lubrication systems, spindle calibration, or axis alignment checks—but they’re built for longevity under daily use.

Side-by-side cost breakdown of small vs. desktop 5-axis CNC systems

In contrast, desktop machines often have simpler maintenance routines but may need more frequent replacement of wear components due to lighter construction.

Power consumption, tooling options, and software licensing also vary. Small CNCs might support standard tool holders and industrial CAM software, while desktops often rely on proprietary or open-source solutions with limited expandability.

Be sure to factor in the cost of a 5 axis CNC machine beyond the purchase—this includes software updates, training, and support.

Related reading: Choosing the Right 5-Axis Toolpaths for Efficiency

Best Use Cases for Each Machine Type

Visual comparison of small and desktop 5-axis CNC machines used in different workshop settings

Understanding where each type of machine shines helps clarify the decision. A small 5 axis CNC machine is ideal for:

-

- Job shops needing flexibility for custom or low-volume parts

-

- Businesses machining metal components with tight tolerances

-

- Operators seeking better tool compatibility and durability

Meanwhile, a desktop 5 axis CNC excels in:

-

- Prototyping labs and product development teams

-

- Educational institutions teaching CNC principles

-

- Makers working with softer materials like wax, plastic, or aluminum

Matching the machine’s strengths to your typical job types ensures better ROI and performance.

Want to explore how 5-axis machining supports complex parts? Read our 5-Axis CNC Machining Guide.

Common Pitfalls to Avoid When Choosing

Many first-time buyers make costly mistakes when selecting between a desktop and a small 5-axis CNC machine. Common issues include:

-

- Overestimating capacity needs: Investing in a larger machine than necessary can inflate costs and underutilize resources.

-

- Ignoring software and support: A powerful machine is only as useful as its software ecosystem and technical support availability.

-

- Focusing only on price: While budget matters, the cheapest option may result in limited performance, frequent repairs, or early obsolescence.

Carefully reviewing technical specs, vendor reliability, and long-term goals helps ensure the machine fits both your workflow and your future needs.

Looking to optimize your toolpaths once you choose a machine? Our article on 5‑Axis Toolpath Optimization shares key strategies.

Final Thoughts and CTA

Choosing between a desktop and small 5-axis CNC machine depends on your project scope, workspace, and growth plans. If you’re a workshop looking for a cost-efficient prototyping tool, a desktop model may suffice. However, if you’re aiming for production-level capability or complex geometries, a small industrial 5-axis CNC might be your better investment.

Need help selecting the right machine for your business? Contact us for personalized guidance, or explore our other posts on 5-axis CNC machining and toolpath strategies to plan your next step.

Looking for a structured overview of 5-axis machining principles, machine types, and design tips?

Check out our Complete 5-Axis CNC Machining Guide for more insights.