What services we provide

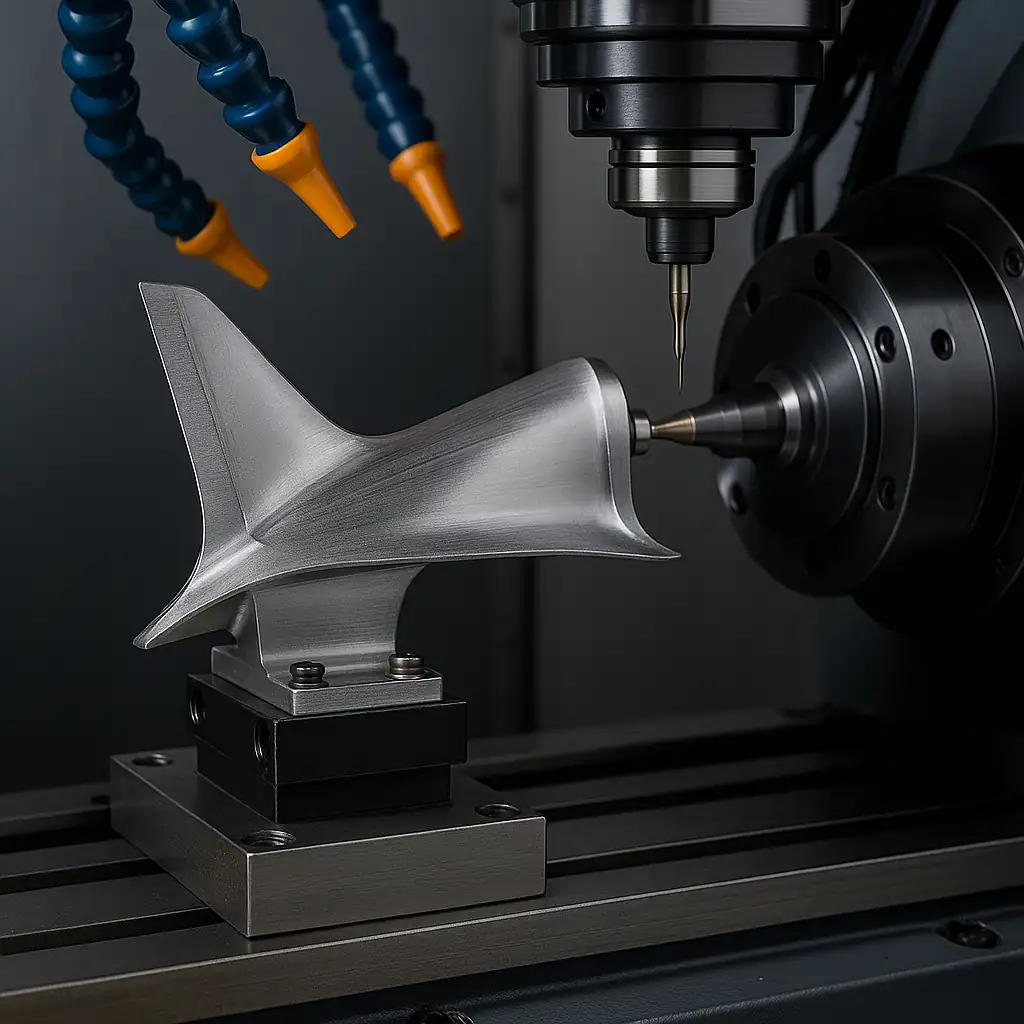

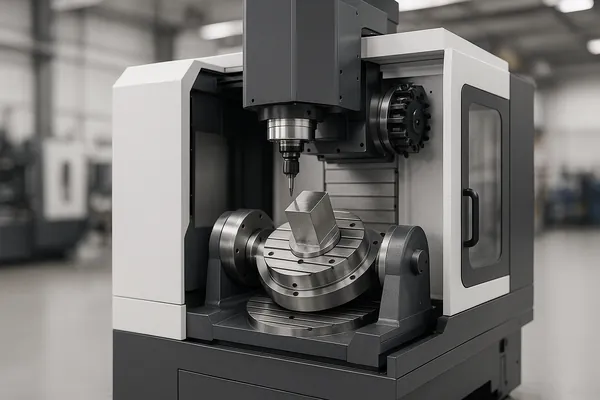

Advanced 5-Axis Technology

Simultaneous 5-axis machining for complex geometries and difficult-to-machine features. State-of-the-art equipment for maximum precision and efficiency.

Single-Setup Manufacturing

Complete complex parts in one setup, reducing errors and improving efficiency. Perfect for complex aerospace and medical components.

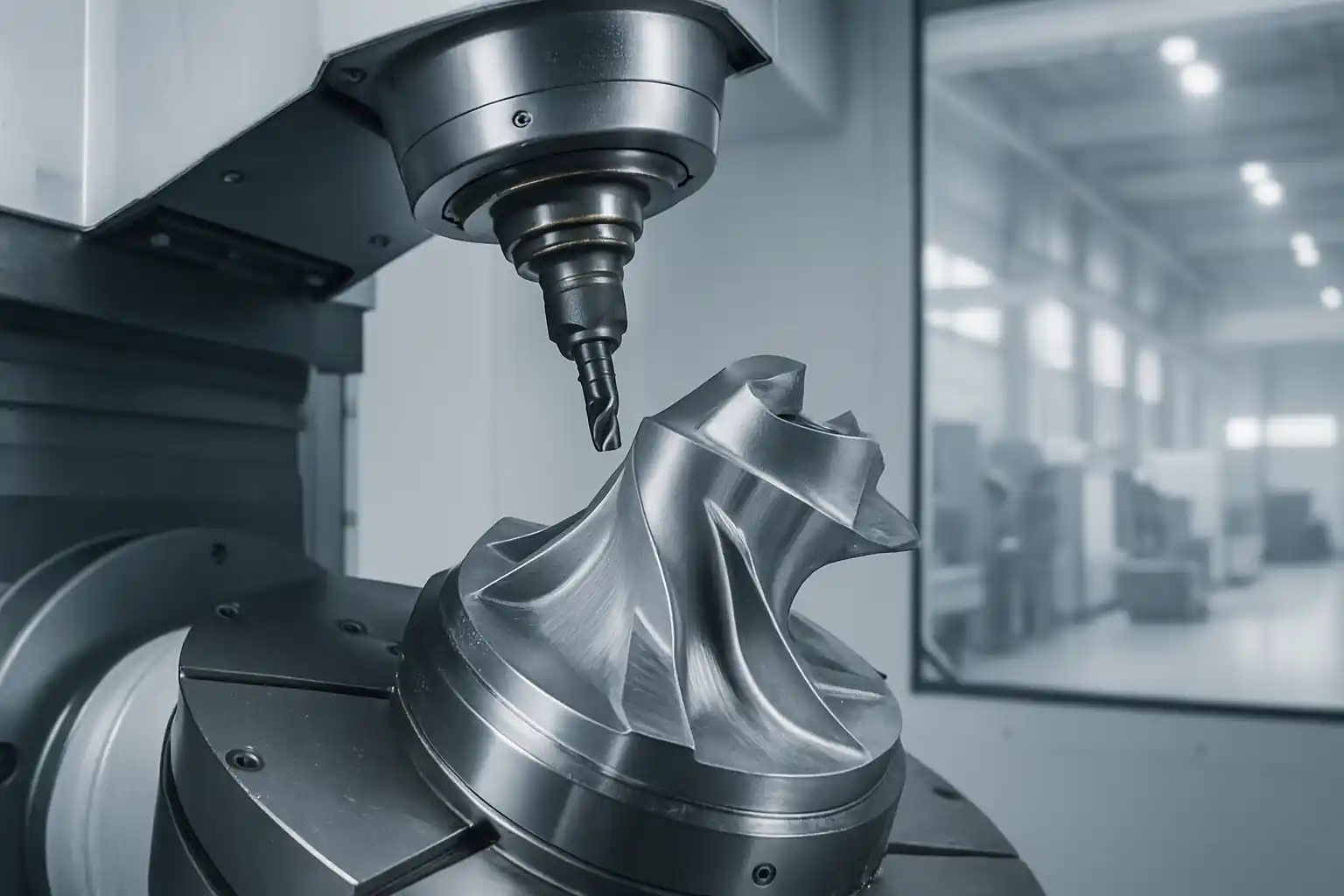

Impeller & Turbine Expertise

Specialized in machining turbine blades, impellers, and complex curved surfaces. High-precision finishing for critical components.

High-End Solutions

Perfect for medical implants, optical components, and precision instruments. Advanced programming for optimal surface quality.

Advanced Applications

Expert in aerospace components, medical devices, and high-end equipment parts. Comprehensive solutions for demanding industries.

Material

| Material | Machinable Grades |

|---|---|

| Stainless Steel |

303 304 316L 410 416 420 17-4PH Duplex 2205 |

| Carbon/Alloy Steel |

1018 1045 4140 4340 8620 Tool Steel (D2, A2, H13) |

| Aluminum Alloy |

2024 5052 6061 6082 7050 7075 |

| Copper/Brass |

Brass (C36000) Bronze (C932) Beryllium Copper Red Copper (T2) |

| Superalloys |

Inconel 625 Inconel 718 Hastelloy |

| Engineering Plastics |

Acetal (Delrin) Nylon PEEK Teflon (PTFE) UHMW-PE PVC Polycarbonate ABS |

CNC General Tolerance

| Parameter | Value (Metric) | Value (Imperial) |

|---|---|---|

| Maximum Part Size | X: 500 mm Y: 400 mm Z: 350 mm |

X: 20 in Y: 16 in Z: 14 in |

| Minimum Part Size | 5 mm x 5 mm x 5 mm | 0.2 in x 0.2 in x 0.2 in |

| Minimum Feature Size | Hole: Ø0.5 mm Wall: 0.5 mm |

Hole: Ø0.02 in Wall: 0.02 in |

| General Tolerance | ±0.025 mm | ±0.001 in |

| Positional Tolerance | ±0.015 mm | ±0.0006 in |

| Flatness Tolerance | 0.02 mm | 0.0008 in |

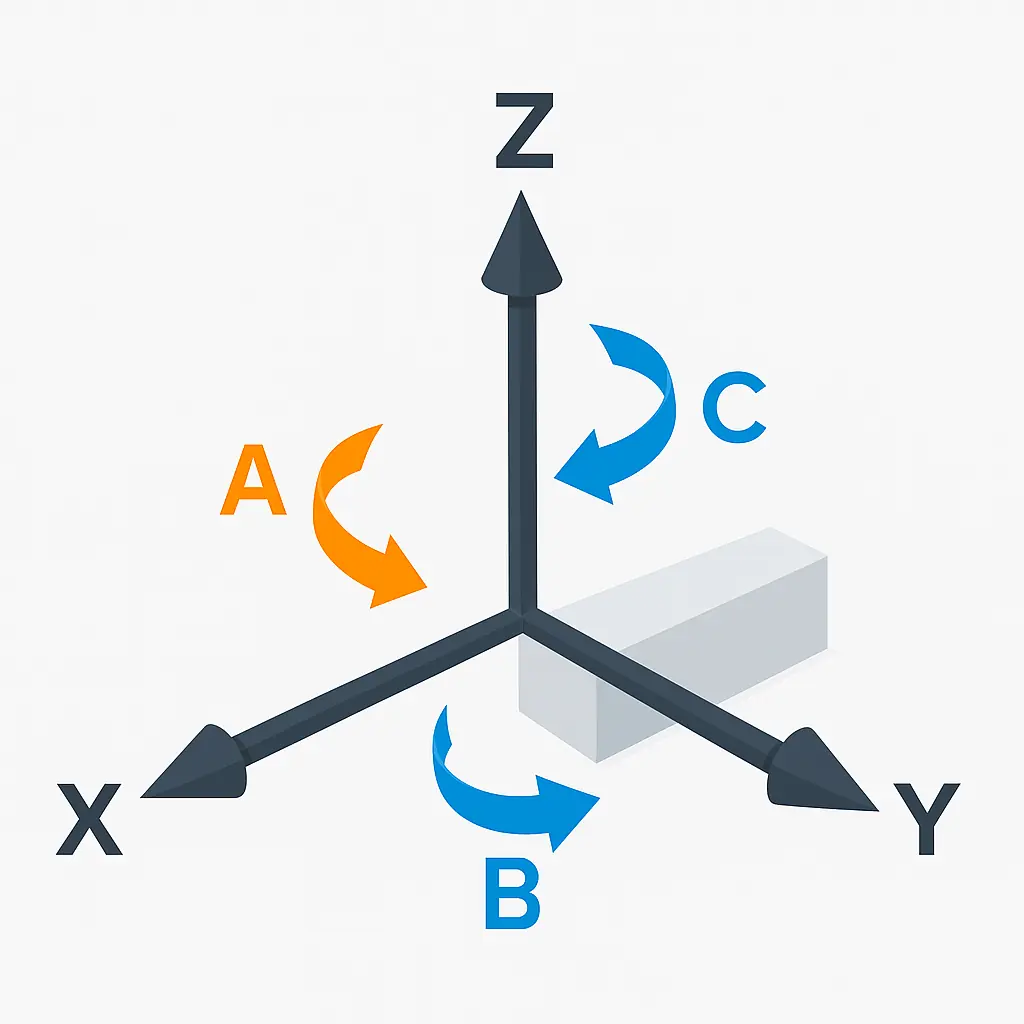

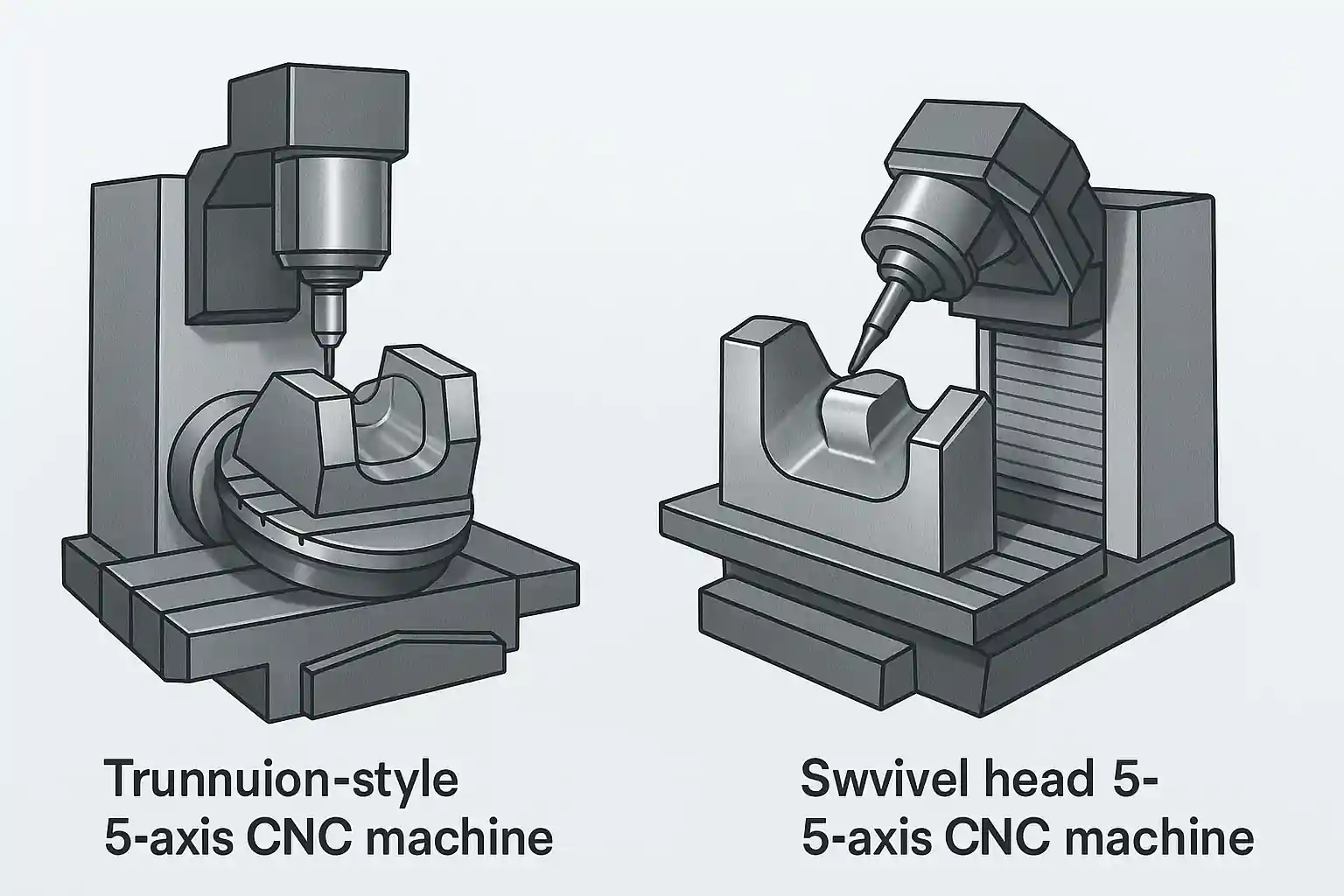

What is 5-Axis Machining?

5-axis machining is an advanced CNC milling process that allows a cutting tool and a workpiece to move simultaneously along five different axes. Unlike traditional 3-axis machining, a 5-axis machine can cut complex, multi-sided parts in a single setup without the need for manual repositioning. This process is highly efficient for creating intricate, contoured parts, significantly improving precision, reducing production time, and delivering a superior surface finish.