Introduction: Ushering in a New Era of Precision Manufacturing

In the modern manufacturing landscape, the relentless pursuit of higher precision, more complex geometries, and shorter production cycles continues. It is against this backdrop that 5 axis machining technology has rapidly emerged as a pivotal force driving industrial progress. This advanced cutting method, powered by Computer Numerical Control (CNC) technology, produces parts of the highest quality, operating on principles similar to sculpting, progressively removing excess material from a solid block until the final desired object is obtained.

The core of 5-axis technology lies in its unique synchronous capability, allowing it to operate a cutting tool or workpiece simultaneously along five different axes. This functionality significantly enhances the precision, complexity, and efficiency of machining operations, thereby expanding manufacturing boundaries.

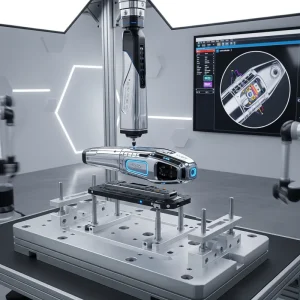

This image captures a typical scenario in advanced manufacturing, where 5-axis machining enables the precise and efficient production of complex parts. It highlights the role of automation and CNC technology in shaping the future of industrial production.

This is not merely an incremental improvement over traditional methods; it represents a fundamental paradigm shift from sequential, multi-setup processes to integrated, single-setup operations. This guide provides technical professionals with an in-depth understanding of 5-axis machining. It covers its fundamental principles, advantages, challenges, industrial applications, and best practices industrial applications, and key best practices for effective implementation and optimization. For a broader overview, you can also explore our article on 5-Axis CNC Machining: Advantages, Capabilities, and Applications.

1. Core Principles of 5-Axis Machining: The Art of Beyond-3D Movement

Explaining the Five Axes of Motion (X, Y, Z, A, B/C)

Traditional CNC machines primarily move along three linear axes: the X-axis (horizontal movement), the Y-axis (vertical movement), and the Z-axis (depth or movement towards/away from the workpiece). 5-axis machines retain these three fundamental linear axes while introducing two additional rotary axes:

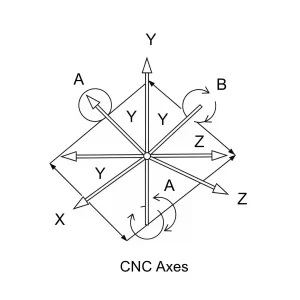

This principle diagram vividly explains the five axes of motion (X, Y, Z linear and A, B/C rotary) that define 5-axis machining. Understanding these axes of motion is fundamental to grasping the advanced capabilities of 5-axis CNC technology.

- A-axis: This rotary axis typically rotates around the X-axis, allowing the cutting tool or the workpiece itself to tilt. This capability facilitates machining from various angles and orientations.

- B-axis: The B-axis involves rotation around the Y-axis. Similar to the A-axis, the B-axis permits tilting and swiveling, providing greater freedom to approach the workpiece from varied perspectives.

- C-axis: In some configurations, the C-axis represents rotation around the Z-axis, commonly found in trunnion table setups. The “five” in 5-axis refers to the total number of directions the cutting tool can move. These two additional rotary axes facilitate advanced rotation and movement, ensuring optimal contact between the cutting tool and the material. This simultaneous operation is crucial, as it allows up to five faces of a part to be machined in a single clamping. To delve deeper into the fundamental axes, read our guide on What Are the 5 Axes in CNC Machining.

Why is Simultaneous Movement Crucial?

The integration of the A and B (or C) axes is not merely about adding more degrees of freedom. Its profound impact lies in enabling the cutting tool to maintain an optimal, often tangential, relationship with the workpiece surface throughout the machining process. This “tangential to the cutting surface” capability directly leads to improved machining quality and efficiency, allowing more material to be removed with each tool pass. Crucially, it mitigates the detrimental issue of zero linear velocity at the center point of a ball end mill—a common limitation in 3-axis machining that leads to poor surface finish and accelerated tool wear. This technical advantage is a core driver of 5-axis machining’s superiority: the machine can not only access more areas but also perform higher-quality cuts within those areas. This directly translates to superior surface finishes, significantly reducing or eliminating the need for costly secondary operations like polishing, and substantially extending tool life, leading to significant cost and quality benefits.

Main 5-Axis Machine Configurations

The fundamental distinction between different types of 5-axis machines lies in the placement of their rotary axes: either within a swiveling tool head that operates on stationary material or through a moving table that thereby moves the workpiece itself.

-

Integrated Trunnion Table

- (typically A-C rotary axis configuration): This configuration achieves its range of motion by moving the table, making it particularly suitable for securely clamping larger workpieces. It offers superior undercut capabilities, with a typical rotation range of +/-110 degrees, exceeding the rotational limits of many swivel-head designs. This design contributes to a larger effective work volume, as it does not need to account for the space occupied by a swiveling tool head. This configuration is often preferred by shops transitioning from 3-axis to 5-sided machining, as its approach is conceptually similar to their existing linear machining processes.

-

Swivel Head with Rotary Table

- (typically B-C rotary axis configuration): In this setup, the machine’s spindle head moves around a stationary table. It is best suited for machining heavier parts, given that the workpiece remains static on the table. The large, stationary table offers superior versatility, allowing for the addition of vises to facilitate finishing the sixth side of a part or performing traditional 3-axis work concurrently with 5-axis operations. As the swivel head itself tilts the tool, it minimizes tool interference with the machine’s spindle head, allowing for clearer tool access to the workpiece. This configuration also improves chip control when the machine is run horizontally.

-

Traveling Column Design:

- This 5-axis machine is characterized by enhanced rigidity and stability due to minimized movement of its primary machine components. This inherent stability significantly contributes to achieving superior repeated accuracy and design repeatability.

The detailed elaboration on different 5-axis machine configurations (trunnion vs. swivel head) and their specific advantages (e.g., handling heavier parts, superior undercut capabilities, maximizing work volume, optimizing chip control, and offering versatility) clearly indicates that the choice of a 5-axis machine is far from a one-size-fits-all decision. Instead, it represents a strategic decision that must be carefully guided by the typical characteristics of the parts to be machined (such as size, weight, geometric complexity, and the presence of specific features like undercuts) and overall production objectives (e.g., prioritizing maximum work volume versus the ability to machine extremely heavy components). For a more in-depth look at these configurations, refer to our article on Types of 5-Axis CNC Machines: Trunnion vs. Swivel Head Designs.

5-Axis vs. 3-Axis, 3+2 Axis Machining: Key Differences

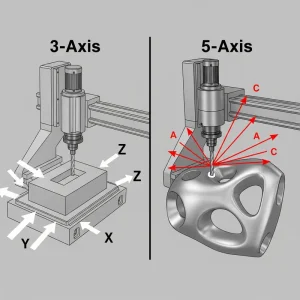

This diagram clearly illustrates the fundamental differences between 3-axis and 5-axis machining, emphasizing the expanded tool motion and workpiece accessibility enabled by the two additional rotary axes in 5-axis CNC machining. This capability is crucial for reducing setups and achieving higher precision.

| Feature/Aspect | 3-Axis Machining | 3+2 Axis Machining (Positional 5-Axis) | 5-Axis Machining (Simultaneous) |

|---|---|---|---|

| Number of Axes | X, Y, Z | X, Y, Z + 2 rotary axes | X, Y, Z + 2 rotary axes |

| Rotary Axis Function | None | Axes position part/tool to fixed angle, then 3-axis machining occurs | Axes move continuously and simultaneously during cutting, maintaining optimal tool-workpiece contact |

| Simultaneous Movement | No | No (positional, not continuous) | Yes (simultaneous) |

| Setup Requirements | Often requires multiple manual setups | Fewer than 3-axis, multi-sided parts often “done in one” | Most complex parts require only one setup |

| Tool Length/Rigidity | Often requires longer tools, leading to lower rigidity | Allows for shorter, more rigid cutting tools | Allows for shortest, most rigid tools |

| Surface Finish | Best for simple, flat surfaces and basic cuts | Capable of steep walls, undercuts in cavities, and intricate features | Ideal for extreme geometries, complex curved surfaces, intricate designs, contoured edges |

| Part Complexity | Low | Medium | High |

| Primary Applications | Flat surfaces, basic components (e.g., rectangular plates) | Roughing operations, positioning for faster feed rates, multi-sided part features | Finishing operations, aerospace, medical, military, energy components |

| Programming Complexity | Lower | Medium | Higher |

| Initial Cost | Lower | Lower than simultaneous 5-axis, higher than 3-axis | Highest |

| Cycle Time | Longer due to multiple setups | Reduced | Significantly reduced |

| Human Error Potential | Higher due to manual repositioning | Significantly reduced | Significantly reduced |

2. Why Choose 5-Axis? Unparalleled Advantages Explained

5-axis machining technology holds a central position in modern manufacturing due to a series of significant advantages that are difficult to achieve with traditional machining methods.

Unmatched Precision for Complex Geometries

5-axis machining is renowned for producing parts of the highest quality. The extended five axes of motion inherently provide significantly greater precision compared to traditional 3-axis machining. This technology excels at handling complex geometries and contours, enabling the efficient and accurate production of parts with smooth shapes and intricate contoured edges.

This image illustrates the extraordinary capability of 5-axis machining to produce complex geometries and intricate designs with unmatched precision. Such precision parts are critical for demanding sectors like aerospace components and advanced mechanical systems.

Its primary advantage lies in its ability to machine highly complex shapes, including those defined by Geometric Dimensioning and Tolerancing (GD\&T) specifications. This includes effortlessly creating the intricate curves, angles, and contours required for aerospace engine components, as well as complex multi-sided parts. As we will detail in the “Industry Focus” section, leading manufacturers like MINHE, with their state-of-the-art 5-axis simultaneous machining capabilities, can provide exceptional precision and efficiency for challenging geometries. This enables them to meet the demands for extreme precision in high-requirement industries such as aerospace and medical devices.

Significantly Reduced Setups and Cycle Times

5-axis machines embody a “one and done” approach, possessing the inherent ability to rotate the workpiece and access all its surfaces in a single operation, thereby eliminating the need for manual repositioning common in 3-axis machining. This capability drastically reduces the necessity for multiple setups and manual part handling, streamlining the entire manufacturing process and significantly boosting overall efficiency. The reduction in setups directly translates to shorter lead times and significantly reduced part production cycle times. Fewer repositioning steps not only save valuable time but also enhance overall operational efficiency, leading to faster production times and increased throughput. The “one and done” approach and the significant reduction in “workpiece repositioning” directly address a critical pain point inherent in traditional machining: human error and loss of precision introduced during multiple manual setups. By maintaining a consistent “zero” or “home” location throughout the machining process, 5-axis technology significantly improves “feature-to-feature accuracy”. This allows companies like MINHE, which offer efficient manufacturing services, to achieve fast turnaround times and provide cost-effective solutions to their clients.

Superior Surface Finish and Extended Tool Life

This detailed view highlights the dynamic cutting process in 5-axis machining, where optimized tool engagement leads to excellent surface finish and extended tool life. The precision of CNC machining is evident in the controlled material removal.

5-axis machining facilitates more efficient cutting angles, which directly contributes to achieving superior surface finishes and significantly extending tool life. Maintaining the cutting tool tangential to the cutting surface is crucial for optimizing machining quality and efficiency. A major advantage is its ability to avoid the detrimental issue of zero linear velocity at the center point of a ball end mill—a common occurrence in 3-axis machining that severely degrades surface quality. By positioning the part closer to the cutting tool, shorter, more rigid tools can be used. These shorter tools are inherently less susceptible to vibration at higher cutting speeds, which directly and positively impacts the final surface finish. The improved tool life is a direct result of the machine’s ability to maintain optimal cutting positions and a constant chip load. Achieving higher precision and superior surface finishes directly from the machining process often eliminates the need for subsequent secondary operations like grinding or polishing, saving both time and cost. MINHE’s capability in precision machining, achieving tolerances up to ±0.01mm, is a testament to the advantages of 5-axis machining in delivering superior surface finishes.

Enhanced Design Freedom and Part Complexity

The inherent ability to approach a workpiece from multiple angles provides unparalleled flexibility, enabling complex and previously challenging cuts to be executed. 5-axis machines possess the unique capability to cut and produce the most intricate and highest quality parts, including highly complex curved 3D surfaces. This technology is ideally suited for creating components that demand extremely complex geometries, exhibit high quality, require tight tolerances, or even for performing traditional machining operations on odd or tilted surfaces. The statement “ability to access areas that would pose challenges or be impossible for a 3-axis machine” indicates that this technology is more than an incremental improvement; it fundamentally enables entirely new manufacturing possibilities. Its breakthrough in “machining parts with extreme geometries complexity” and handling the “unique and geometrically complex nature of the parts” further confirms this. This positions 5-axis machining as a powerful enabler of innovation, freeing engineers and designers from the constraints of traditional manufacturing processes. For detailed guidance on designing such parts, refer to our article on Designing Parts for 5-Axis CNC Machining: Best Practices & Pitfalls.

Overall Cost-Effectiveness and Productivity Gains

Despite a higher initial capital outlay, 5-axis machining can prove to be a highly cost-saving and productive investment in the long run. It dramatically shortens the overall production process chain and simplifies production management, planning, and scheduling, especially when dealing with complex workpieces. The reduced need for multiple fixtures is a significant advantage, as parts can often be clamped and machined in a single operation. This directly translates to lower fixturing costs and reduced maintenance requirements. The technology also enhances overall productivity and the repeatability of manufactured parts. MINHE’s ability to offer “competitive pricing” while consistently delivering “high quality, high precision, and reliability”, and maintaining ISO 9001:2015 certification, highlights the overall cost-effectiveness of this advanced machining. This dual advantage of quality and cost-effectiveness is significantly appealing to clients, especially in cost-sensitive yet quality-critical industries.

3. Challenges and Considerations in 5-Axis Implementation

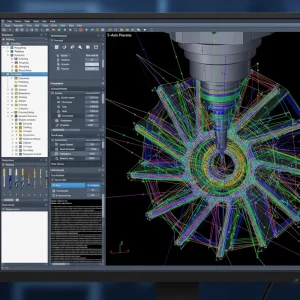

This detailed view showcases a complex CAM (Computer-Aided Manufacturing) software interface used in 5-axis machining. It displays precise multi-axis tool path planning for an intricate part, such as a turbine blade, highlighting the professionalism and technical depth required for 5-axis programming.

While 5-axis machining offers numerous advantages, its implementation also comes with certain challenges that require careful planning and investment from businesses.

Higher Initial Investment and Operating Costs

The acquisition cost of 5-axis CNC machines is higher, encompassing both the machine hardware and its foundational software. While the long-term return on investment often outweighs the initial outlay, the upfront price remains a significant concern for many potential adopters. To successfully adopt 5-axis technology, a meticulous cost-benefit analysis and a strong argument for Return on Investment (ROI) are absolutely crucial. The numerous advantages detailed in Section II (e.g., reduced setups, improved quality, extended tool life, simplified management) must be quantified to overcome this initial financial hurdle. For more details on pricing, refer to our 5-Axis CNC Machine Pricing, Services, and Buying Guide.

Complexity in Programming and Tool Path Generation

Programming 5-axis machines is inherently more challenging, demanding a higher level of programming expertise and operational execution. The abstract nature and specialized requirements of managing additional rotary axes and spatial trajectories add to this complexity. The use of high-quality Computer-Aided Manufacturing (CAM) software (e.g., CAM Software Services or CAM Software Guide if applicable) is essential for generating efficient tool paths and proactively anticipating potential collisions. Post-processors play a critical role in translating the design data generated by CAM programs into the specific G-code that CNC machines can interpret and execute. This translation capability significantly enhances the versatility and ease of use of the entire machining operation. Mastery of advanced programming techniques, including G-code, M-code, and custom macro programming, is vital for the efficiency and precision of 5-axis operations. To learn more about optimizing tool paths, check out our article on 5-Axis Toolpath Optimization: Strategies for Precision and Efficiency.

Demands on Operator Skill and Training

Operating 5-axis machinery places higher demands on operator skills. The operator’s proficiency and knowledge are key factors in preventing costly collisions during the machining process. Ongoing training in CAM software usage, CNC machine control, and adherence to safety best practices is crucial for minimizing the risk of human error. The range of critical skills required for a 5-axis operator is extensive: advanced technical skills (including familiarity with various cutting tools, materials, machining techniques, metrology, and machine maintenance and troubleshooting), strong mathematical aptitude (covering arithmetic, trigonometry, geometry, and algebra for interpreting blueprints and creating tool paths), meticulous attention to detail, strong problem-solving abilities, effective communication skills, proficient time management, the ability to perform effectively under pressure, and a high degree of adaptability.

Machine Rigidity and Specific Application Limitations

Compared to 3+2 axis machining, continuous 5-axis machines typically have comparatively lesser axis rigidity, which often makes them better suited for finishing operations involving more complex shapes. It is important to note that not all parts necessarily require full 5-axis simultaneous machining; in some cases, 3+2 positional CNC machining can prove to be a more efficient and appropriate solution. Furthermore, 5-axis machining may not be the optimal or even viable solution for all applications. Consider exploring options for a small 5 axis cnc machine if space or specific application needs are a concern.

4. Materials and Applications: The Broad Horizon of 5-Axis Machining

5-axis CNC machining is highly versatile, capable of processing a wide range of materials and playing an indispensable role across numerous demanding industries.

Common Machinable Materials

5-axis CNC machining is capable of processing both metal materials and plastic materials.

- Metal Materials: Common metals include titanium, aluminum, copper, as well as bronze, stainless steel, tool steel, and cast iron.

- Plastic Materials: Frequently machined plastics include ABS plastic, nylon, polycarbonate, as well as acrylic, acetal/Delrin, HDPE, PEEK, PEI (Ultem), PET, and polystyrene.

- Composite Materials: This technology is also applicable to various composite materials. Notably, MINHE possesses expertise in machining aluminum alloys, employing optimized cutting parameters to ensure excellent machining results. This further demonstrates their deep, material-specific technical proficiency.

Common Materials for 5-Axis Machining

| Material Category | Specific Examples | Suitability/Common Applications |

|---|---|---|

| Metals | Titanium, Aluminum Alloys, Copper, Bronze, Stainless Steel, Tool Steel, Cast Iron | High strength-to-weight ratio, high-temperature resistance, biocompatibility, general industrial components, high-strength applications |

| Plastics | ABS, Nylon, Polycarbonate, Acrylic, Acetal/Delrin, HDPE, PEEK, PEI (Ultem), PET, Polystyrene | Prototyping, functional components, medical devices, electronic components, high-performance applications |

| Composites | Various composite materials | High strength, lightweight, specific environmental resistance |

Key Industry Applications

5-axis CNC machining is a brilliant solution that has profoundly transformed advanced industrial sectors.

-

Aerospace:

- This industry demands components that are not only structurally sound but also extremely lightweight and aerodynamically efficient. 5-axis machines excel at creating smooth shapes and intricate contoured edges, which are crucial for aerospace applications. Specific applications include complex geometry machining for engine components (like turbine blades and impellers, ensuring optimal performance and fuel efficiency), efficient production of aircraft structural parts (like fuselage frames and wing ribs, guaranteeing precision, strength, and perfect alignment), and facilitating the exploration of new materials (such as composites) and advanced lightweight designs. MINHE explicitly lists this sector as a core focus.

-

Medical Devices:

- This field requires components with extremely high precision, stringent quality, and tight tolerances. 5-axis machining plays a critical role in producing precise medical devices, implants, and various healthcare equipment, which are often small and geometrically complex. For medical equipment manufacturers, this technology leads to significant cost savings and increased productivity.

-

Automotive Components: 5-axis machining

- is widely used in the automotive industry for manufacturing parts with complex shapes and demanding geometries.

-

Industrial Equipment:

- This broad category also benefits from the precision and complexity-handling capabilities of 5-axis machining.

-

Electronics & Semiconductors:

- Producing intricate and high-precision components for these industries is another key application area for 5-axis technology.

-

Military/Defense: 5-axis CNC machining

- is crucial for manufacturing components for precise military equipment, including submarine parts, turbine and compressor blades, high-performance engine parts, smart weapons, advanced sensors, and stealth applications.

-

Energy Production:

- The energy sector frequently requires complex and advanced components for systems like solar power systems and power stations. These parts are machined with 5-axis technology to ensure exceptional durability and stability in demanding operational environments.

-

The consistent highlighting of high-stakes industries—

- aerospace, medical, military, automotive, and energy—where “precision and complexity play pivotal roles”, indicates a strong, almost symbiotic relationship between the demands of these sectors and the capabilities of 5-axis technology. MINHE’s explicit strategic focus on these specific industries further reinforces this critical alignment.

5. Best Practices: The Path to 5-Axis Excellence

To fully harness the potential of 5-axis machining and effectively navigate its complexities, a series of best practices must be followed.

Leveraging Advanced CAM Software and Post-Processing

Advanced Computer-Aided Manufacturing (CAM) software is essential for efficiently programming complex tool paths and proactively anticipating potential collisions. Key features within CAM software, such as automatic tool orientation adjustments and dynamic collision detection, are indispensable for maintaining operational safety and achieving desired precision. CAM programs are responsible for mapping design data

into precise tool paths and machine movements. A crucial component, the post-processor, subsequently translates the CAM data into the specific G-code that CNC machines can interpret and execute. This translation capability significantly enhances the versatility and ease of use of the entire machining operation. Proficiency in leading CAD/CAM software platforms (e.g., AutoCAD, SolidWorks, Mastercam) is vital, as it substantially improves design accuracy and overall production efficiency.

Optimizing Tool Selection and Innovative Workholding Solutions

Using cutting tools that are excessively long or unsuitable for a specific 5-axis machine or operation significantly increases the risk of collisions with the workpiece or other machine components. Therefore, it is strongly recommended to carefully select tools with appropriate length and the correct angle to perform the required work. Shorter cutting tools are inherently less susceptible to vibration at higher cutting speeds, a characteristic that directly contributes to superior surface finishes. Implementing innovative workholding solutions is crucial for ensuring comprehensive and unobstructed access to the workpiece. This approach minimizes setup times and significantly enhances machining accuracy. Employing versatile and adaptable fixtures that permit unrestricted tool paths is essential, facilitating the execution of complex machining operations. Improper clamping techniques can lead to workpiece movement during machining, potentially resulting in collisions with the tool or spindle. Operators must ensure that parts are properly clamped and that the fixture itself does not interfere with the programmed tool path.

Collision Avoidance and Machine Calibration Strategies

Confirming machine calibration is a foundational step; understanding the system’s unique kinematic configuration (e.g., table-table, spindle-spindle, or table-spindle type) is crucial, as it directly influences how axes move and potential interference zones. Performing comprehensive simulations prior to initiating production runs is a non-negotiable best practice. Precisely defining and maintaining the machine’s accuracy and motion stability is paramount. Setting appropriate rotational and linear axis limits within the CNC machine control software is vital for preventing unexpected movements that could lead to collisions.

Employing well-planned roughing processes is crucial for reducing unnecessary movements and minimizing abrupt changes in direction, thereby mitigating collision risks. Implementing pre-operation checklists before running programs on the CNC machine is an excellent safety practice. Thorough checks of the tool path, part fixture, and tooling are imperative before commencing the machining cycle to prevent costly errors. Modern 5-axis machines are increasingly equipped with real-time monitoring systems and advanced sensors capable of detecting potential collisions and automatically stopping the machining process before damage occurs. Regular calibration checks are essential to ensure all axes remain perfectly aligned, thereby preserving machining accuracy.

The Importance of Operator Training and Continuous Skill Development

The operator’s knowledge and expertise are fundamental to successfully avoiding collisions in complex 5-axis operations. Providing ongoing training in effective CAM software usage, proficient CNC machine control, and adherence to established safety best practices is crucial for significantly reducing the incidence of human error. The demanding nature of this role requires a broad range of skills: including advanced technical capabilities, strong mathematical aptitude (e.g., trigonometry, geometry, and algebra for precise tool path calculations), meticulous attention to detail, strong problem-solving abilities, effective communication, efficient time management, the ability to perform effectively under pressure, and a high degree of adaptability. Proficiency in CAD/CAM software and advanced programming techniques is particularly important for modern 5-axis professionals.

Essential Skills for 5-Axis CNC Professionals

| Skill Category | Specific Skills |

|---|---|

| Technical Skills | Familiarity with various cutting tools, materials, and machining techniques; understanding of metrology and precision measurement tools (e.g., micrometers, calipers); knowledge of machine maintenance and troubleshooting techniques; ability to perform routine maintenance tasks (e.g., lubrication, cleaning, tool changing). |

| Programming Skills | Mastery of advanced programming techniques (G-code, M-code, custom macro programming); proficiency in leading CAD/CAM software (e.g., AutoCAD, SolidWorks, Mastercam); multi-axis machining expertise; deep understanding of material properties to optimize tool and parameter selection. |

| Analytical & Problem-Solving | Ability to analyze and interpret complex technical drawings and specifications; capability to identify and troubleshoot issues with CNC machines and software; ability to collaborate effectively with engineers and team members to develop and implement solutions. |

| Soft Skills | Meticulous attention to detail; clear and effective communication (with colleagues, designers, clients); strong time management (prioritizing tasks, optimizing machine utilization); ability to work effectively under pressure and make informed decisions; high adaptability and willingness to embrace change; fostering a growth mindset focused on continuous learning. |

| Mathematical Aptitude | Solid foundation in arithmetic operations (addition, subtraction, multiplication, division); proficiency in working with decimals, fractions, and percentages; knowledge of trigonometry and geometry for interpreting blueprints and creating tool paths; familiarity with algebraic formulas and equations for calculating speeds, feeds, and other machining variables. |

6. Industry Focus: MINHE’s Expertise in 5-Axis Machining

This image offers a glimpse into a modern, high-precision manufacturing facility, featuring multiple 5-axis CNC machines actively engaged in complex machining operations. It embodies the advanced capabilities and organized environment typical of expert partners like MINHE.

As a leading manufacturer with over 15 years of experience in precision CNC machining, MINHE fully embodies the powerful potential of 5-axis machining technology and its value in practical applications.

Overview of MINHE’s Capabilities and Experience

Since 2008, MINHE has specialized in the manufacturing of precision parts, covering the entire spectrum from prototyping to mass production, consistently delivering high-precision, high-quality, and reliable CNC machining solutions to global clients. As highlighted in the “Core Principles of 5-Axis Machining” section of this guide, 5-axis machining is key to achieving complex geometries. MINHE, leveraging its state-of-the-art 5-axis simultaneous machining technology, is capable of providing exceptional precision and efficiency for challenging and complex components. Furthermore, MINHE excels in precision manufacturing, consistently achieving tight tolerances of up to ±0.01mm. They possess expertise in machining aluminum alloys, employing optimized cutting parameters to ensure excellent machining results. MINHE’s extensive operational history of “over 15 years of experience” and its specialization in “precision parts from prototype to mass production” indicate a mature and highly robust operational capability. Their explicit mention of “optimized cutting parameters” specifically for aluminum alloy machining further underscores their meticulous, material-specific technical know-how. For potential clients, MINHE represents a low-risk, high-reliability manufacturing partner. If you’re looking for a reliable 5 axis CNC machining center (Please verify if this page exists; if not, remove or replace with another service link) or need 5 axis CNC machining services, MINHE can provide cost-effective solutions.

Commitment to Quality: ISO 9001:2015 Certification and Advanced Inspection

In the sections “Why Choose 5-Axis?” and “Best Practices,” we emphasized the importance of quality control. MINHE is a prime example of this philosophy in practice. As an ISO 9001:2015 certified CNC machining facility, MINHE adheres to internationally recognized quality management standards. They utilize advanced Coordinate Measuring Machine (CMM) inspection technology and maintain a rigorous 100% quality control policy, meticulously ensuring that all manufactured products meet precise specifications. Client testimonials consistently highlight MINHE’s ISO certification and robust quality control processes as key factors instilling complete confidence in their services.

Comprehensive Service Offerings and Industry Solutions

MINHE provides a wide range of professional CNC machining services designed to meet the stringent requirements of various industries, including aerospace, automotive, medical, industrial equipment, and electronics & semiconductors. As discussed in the “Materials and Applications” section of this guide, these are industries with extremely high demands for precision and reliability. MINHE excels at providing cost-effective manufacturing solutions tailored to specific client needs, whether for small batch production or large-scale manufacturing. MINHE is committed to building long-term partnerships with clients through transparent communication, flexible solutions, and reliable service. To learn more about our specific service capabilities, visit our 5-Axis CNC Machining Services page.

Client Testimonials and Global Reach

MINHE’s clients consistently praise the high quality, precision, and reliability of their CNC machining services. For instance, Tiffany Bright from Seven Investment highlights that MINHE has “consistently delivered high-quality CNC machined parts” with “outstanding precision and attention to detail”. She also commends the team’s “professional approach and quick response time,” making MINHE a “trusted manufacturing partner”. Richard Green from Seven Consulting notes MINHE’s “excellent manufacturing capabilities and reliable service,” specifically mentioning that their “expertise in precision CNC machining has helped us meet our strict quality requirements,” and that their “ISO certification and quality control processes give us complete confidence”. MINHE’s geographical location is in Dongguan, China, and they are dedicated to providing professional CNC machining solutions to global clients. This global service capability, combined with positive client feedback, further solidifies MINHE’s position as a reliable partner in the precision manufacturing sector. For those looking for a 5 axis CNC machine for sale or to understand the 5 axis CNC machine price, contacting MINHE will provide tailored solutions.

Conclusion: Mastering 5-Axis, Shaping the Future

5-axis machining technology is undoubtedly a revolutionary advancement in modern precision manufacturing. It not only elevates part precision and complexity but also delivers significant efficiency and cost benefits to manufacturers by reducing setups, optimizing production processes, and extending tool life. While its higher initial investment and greater demands on operator skills pose certain challenges, these can be effectively overcome through strategic planning, investment in advanced software, and continuous workforce training. Industry leaders like MINHE, with their over 15 years of extensive experience, mastery of advanced technologies like 5-axis machining, stringent quality management systems, and a customer-centric collaborative approach, exemplify how to effectively leverage this technology to deliver exceptional value in high-stakes industries. Choosing the right 5-axis machining partner means you gain not just a supplier, but a strategic ally capable of navigating complexity, enabling innovative designs, and ultimately shaping the future of manufacturing.

Ready to Elevate Your Manufacturing with 5-Axis Precision?

MINHE leverages over 15 years of expertise to provide unparalleled 5-axis CNC machining solutions. Whether your project demands intricate designs, tight tolerances, or cost-effective production, our team is ready to deliver.

Contact MINHE Today to Discuss Your Project